Ec declaration of conformity – Karcher HDS-C 7-11 Steel User Manual

Page 29

-

13

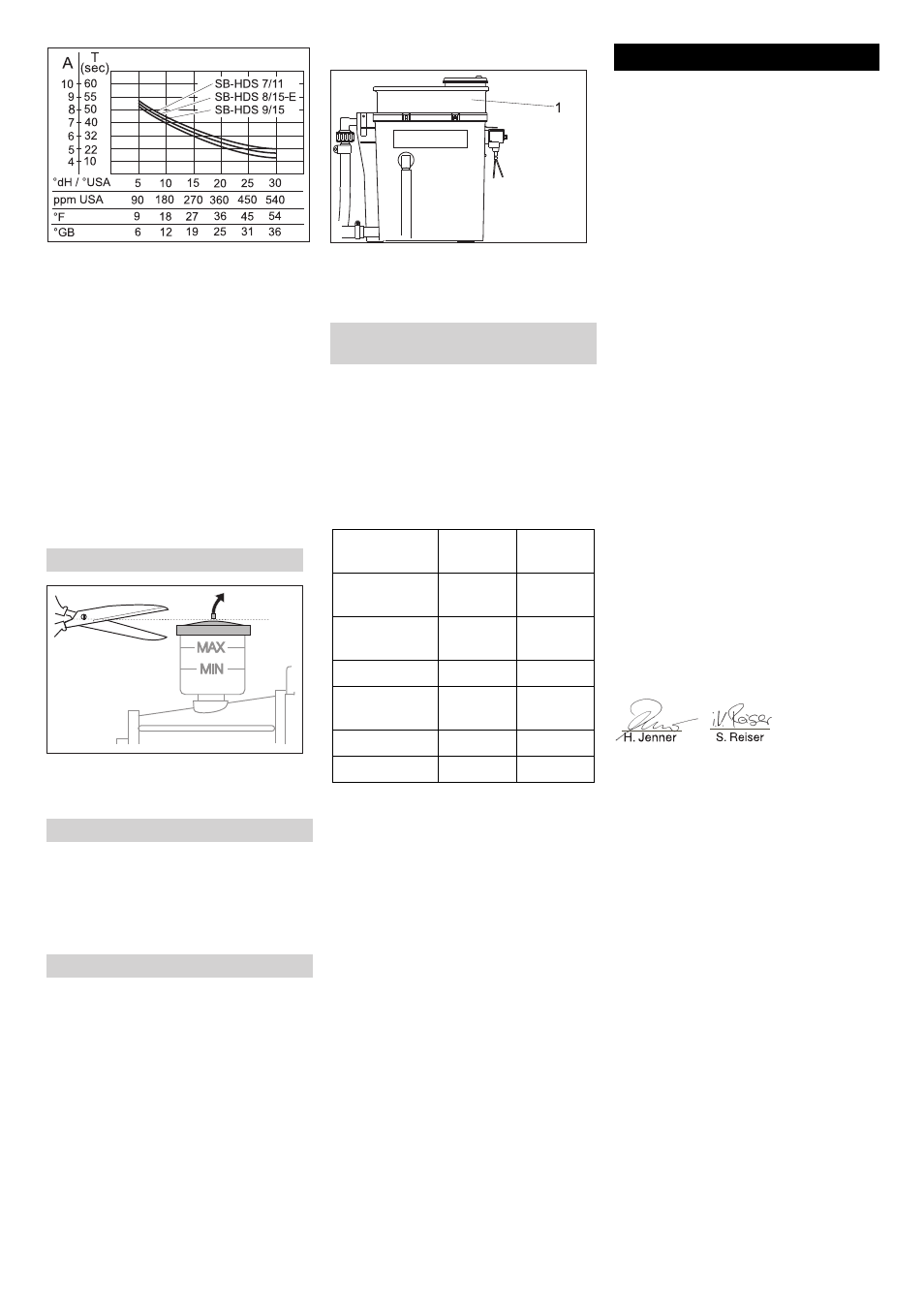

Locate the local water hardness in the

diagram.

Extend the vertical line upward until the

curve for the corresponding point has

been reached.

Draw a horizontal line from the intersec-

tion and read the setting value (A).

Adjust the speed potentiometer in the

switching cabinet to the value that you

have ascertained (A).

Example: For a water hardness of 18 °dH

on the scale for the SB-HDS 9/15, set the

speed potentiometer to position 5.5. This

results in a pause of 27 seconds, i.e. the

solenoid valve will open briefly every 27

seconds.

Close the switching cabinet.

Oil level has to be between MIN and

MAX.

Cut off the top of the oil container.

It is proposed to use the detergent contain-

er without cover. During transport, the con-

tainer can be closed using the delivered lid.

If the container should be kept closed dur-

ing operations, then make a hole of 25mm

diameter in the lid.

Open the detergent container and fill in

detergent.

Only HDS-C 7/11, HDS-C 9/15: Open

the fuel tank and fill in fuel.

1 Dosing container

Remove the cover of the dosing con-

tainer and fill in RM 110.

Close the lid again.

Set main switch to “1”.

Select cleaning programme 3.

Set the switch for continuous opera-

tions/ coin verifier to continuous opera-

tions.

Check burner setting. Rectify the burn-

er settings if the measured values devi-

ate from the values given below.

Note

On finishing checking, close the door of the

plant and check the burner function when

the entire plant is closed. If the burner ex-

tinguishes due to lack of air, you can take

the following steps:

Remove the stopper from the floor of

the plant.

Partially remove the sealing on the door

sides. Also reduce the sealing starting

from the bottom until 20 to 30 cm.

Set the continous operation/ coin verifi-

er switch to coin verifier (only for ABS

Münzprüfer).

We hereby declare that the machine de-

scribed below complies with the relevant

basic safety and health requirements of the

EU Directives, both in its basic design and

construction as well as in the version put

into circulation by us. This declaration shall

cease to be valid if the machine is modified

without our prior approval.

The undersigned act on behalf and under

the power of attorney of the company man-

agement.

Authorised Documentation Representative

S. Reiser

Alfred Kärcher GmbH Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Phone: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, 2011/05/01

Ceck the oil level

Preparing the detergent container

Filling in detergents

Fill in hardening liquid

Initial start-up HDS-C 7/11, HDS-C 9/

15

HDS-C 7/

11

HDS-C 9/

15

Fuel pressure,

approx.

1,1 MPa

(11 bar)

1,1 MPa

(11 bar)

Blower pres-

sure, approx.

2,5 hPa

(2,5 mbar)

4,0 hPa

(4,0 mbar)

CO

2

10...11%

10...11%

Emission tem-

perature

160...180

°C

180...200

°C

Emission loss

max. 9%

max. 9%

Soot values

max. 1

max. 1

EC Declaration of Conformity

Product:

High-pressure cleaner

Type:

1.319-xxx

Relevant EU Directives

2006/42/EC (+2009/127/EC)

2004/108/EC

2000/14/EC

Applied harmonized standards

EN 60335–1

EN 60335–2–79

EN 55014–1: 2006 + A1: 2009

EN 55014–2: 1997 + A2: 2008

EN 61000–3–11: 2000

EN 61000–3–12: 2005

EN 62233: 2008

Applied conformity evaluation method

2000/14/EC: Appendix V

Sound power level dB(A)

HDS-C 7/11

Measured:

70

Guaranteed: 71

HDS-C 8/15

Measured:

70

Guaranteed: 71

HDS-C 9/15

Measured:

87

Guaranteed: 88

CEO

Head of Approbation

29

EN

- HDS-C 9-15 Inox HDS-C 8-15 E Inox HDS-C 9-15 Steel HDS-C 8-15 E Steel HDS-C 7-11 Inox Nettoyeur haute pression HDS-C 9-15 Steel Nettoyeur haute pression HDS-C 9-15 Inox Nettoyeur haute pression HDS-C 8-15 E Inox Nettoyeur haute pression HDS-C 7-11 Inox Nettoyeur haute pression HDS-C 7-11 Steel Nettoyeur haute pression HDS-C 8-15 E Steel HDS-C 9-15 Stal nierdzewna HDS-C 7-11 Stal nierdzewna HDS-C 7-11 HDS-C 8-15 E HDS-C 8-15 E Stal nierdzewna HDS-C 9-15 HDS-C 9-15 Stahl lackiert HDS-C 7-11 Edelstahl HDS-C 8-15 E Stahl lackiert HDS-C 8-15 E Edelstahl HDS-C 9-15 Edelstahl HDS-C 7-11 Stahl lackiert