Karcher HDS-C 7-11 Steel User Manual

Page 25

-

9

ƽ

Danger

Risk of burns due to hot oil or hot parts of

the plant. Allow pump to cool down for 15

minutes before oil change.

Note

Please dispose off used oil only in the col-

lection points provided for them. Please

hand over old oil, if any, only at such plac-

es. Polluting the environment with used oil

is a punishable offence.

1 Oil container lid

2 Oil drain screw

Keep a collection basin for old oil ready.

Remove the lid of the oil container.

Unscrew the oil drain screw and collect

used oil.

HDS-C 7/11, HDS-C 9/15: Replace O

Ring 11x2 (order no: 6.362-458.0) and

turn in the oild drain screw.

HDS-C 8/15-E: Replace copper washer

14x18 (order no. 7.362-005.0) and turn

in the oil drain screw.

Slowly fill in new oil until the "MAX"

marking on the oil container.

Close the oil container with the lid.

Deliver the old oil to the respective col-

lection centres.

Loosen covering nut and take off hose.

Take out sieve.

Note

If necessary turn in screw M8 appr. 5 mm

inwards and therewith pull out sieve.

Clean sieve in water.

Push sieve inwards.

Put on hose.

Tighten covering nut firmly.

There will be calcium deposits in the plant if

the softening plant (optional) is accidentally

out of operation for a long time. Calcium de-

posits in the plant can lead to following dis-

ruptions:

–

higher pipe resistances,

–

reduced heat transfer at the heat ex-

changers,

–

failure of components spoilt on account

of calcium deposits.

In the interest of environmental safety, use

only tested and approved decalcifying

agents (calcium dissolution acids with test

marking) to decalcify. The high pressure

unit should be decalcified using the Kärch-

er calcium solvent.

ƽ

Danger

Only persons trained by Kärcher are au-

thorised to decalcify the plant. Risk of ex-

plosion due to combustible gases! Do not

smoke during decalcification; ensure prop-

er ventilation. Risk of burns injury on ac-

count of acid. Wear protective glasses and

protective gloves.

Unscrew the hand-spray gund and in-

sert the hose in the drainage duct so

that the water can flow freely.

Set the hot water temperature to 40 °C.

Shut off water supply.

Start the washing programme with hot

water until the swimmer container for

fresh water is almost empty.

Add 0.5 litre calcium solvent to the

swimmer tank for fresh water.

Leave the water inlet open until the

swimmer tank for fresh water is full

again.

Switch on the plant briefly and then let

the calcium solvent react. Repeat this

process every 4 to 5 minutes until the

swimmer tank for fresh water is almost

empty.

Open the water inlet and let the wash-

ing programme with hot water run for 5

minutes until the tank is rinsed.

Connect the hand-spray gun to the high

pressure hose.

Caution

Danger of damage to the fuel pump. Do not

interchange the forward and backward flow

pipes for fuel. This can cause the fuel

pump to dry run and get damaged.

Pull out the fuel hoses on the fuel pump.

Remove the fuel tank from the plant.

Rinse the fuel tank thoroughly (allow

the fuel tank rinsed with water to dry

properly).

Dispose off fuel residues according to

environment safety laws.

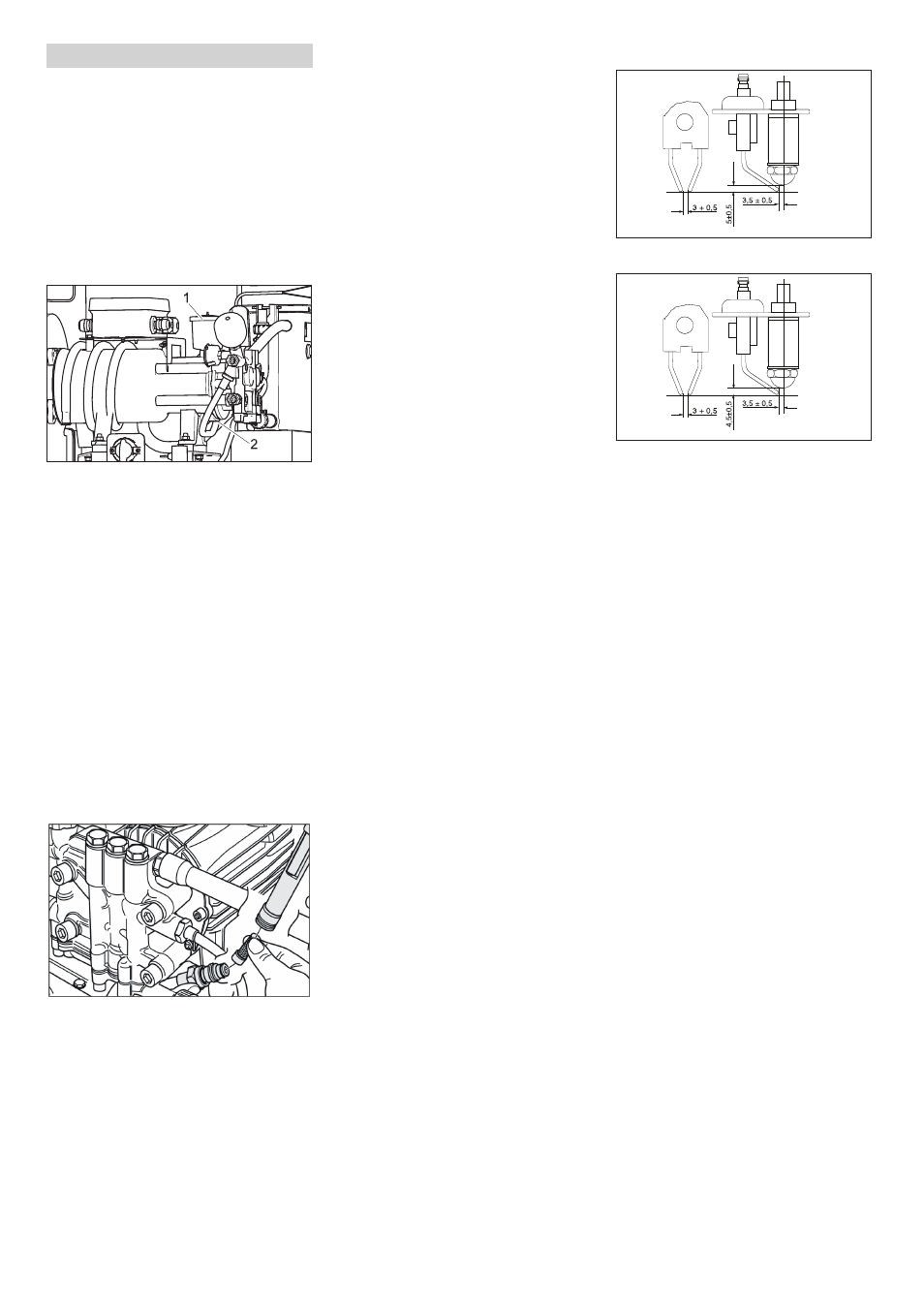

The correct setting of the ignition elec-

trodes is very important for the burner to

function properly. The settings have been

indicated in the above drawing.

Maintenance Works

Oil change

Clean sieve in the water shortage safe-

guard (only HDS-C 7/11, HDS-C 9/15)

Decalcify the heating spiral (only HDS-C

7/11, HDS-C 9/15)

Clean fuel tank (only HDS-C 7/11, HDS-C

9/15)

Electrode setting SB-HDS 7/11

Electrode setting SB-HDS 9/15

25

EN

- HDS-C 9-15 Inox HDS-C 8-15 E Inox HDS-C 9-15 Steel HDS-C 8-15 E Steel HDS-C 7-11 Inox Nettoyeur haute pression HDS-C 9-15 Steel Nettoyeur haute pression HDS-C 9-15 Inox Nettoyeur haute pression HDS-C 8-15 E Inox Nettoyeur haute pression HDS-C 7-11 Inox Nettoyeur haute pression HDS-C 7-11 Steel Nettoyeur haute pression HDS-C 8-15 E Steel HDS-C 9-15 Stal nierdzewna HDS-C 7-11 Stal nierdzewna HDS-C 7-11 HDS-C 8-15 E HDS-C 8-15 E Stal nierdzewna HDS-C 9-15 HDS-C 9-15 Stahl lackiert HDS-C 7-11 Edelstahl HDS-C 8-15 E Stahl lackiert HDS-C 8-15 E Edelstahl HDS-C 9-15 Edelstahl HDS-C 7-11 Stahl lackiert