Maintenance – ROTHENBERGER ROGROOVER 2 - 12 User Manual

Page 34

33

ENGLISH

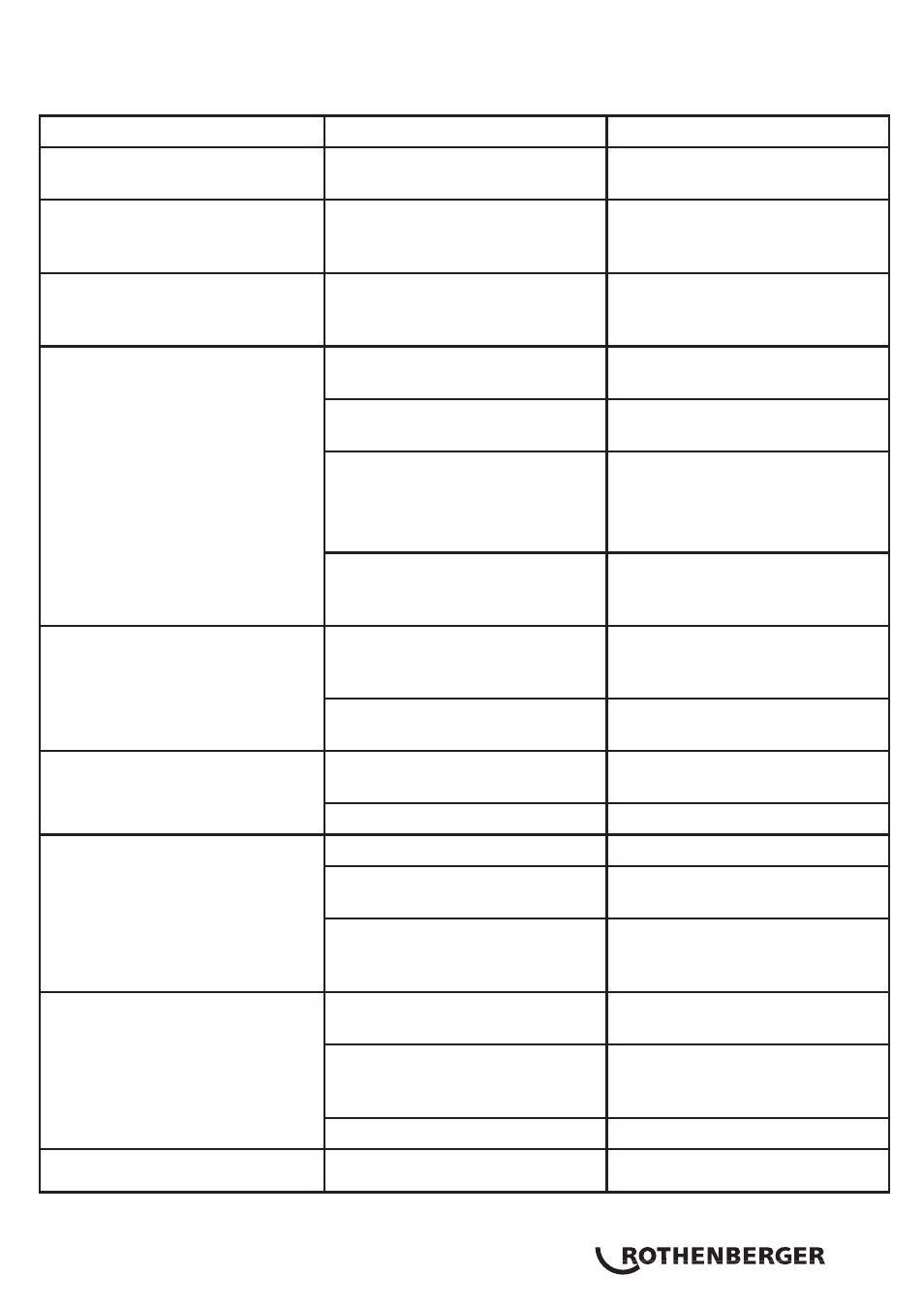

Problem

Possible cause

Solution

The groove is too narrow or too

wide

The roller set does not correspond

to the tube diameter

Replace the roller set for one which

corresponds to the tube diameter

The groove zigzags

The groove is not parallel to the surface

of the tube end

The tube has not been cut square

Cut the tube square

The groove diameter is not uniform

throughout the entire circumference

of the tube

The tube is elliptic

Use a circular tube

The countersinking at the end of

the tube is too large

The roller set does not correspond

to the tube diameter

Replace the roller set for one which

corresponds to the tube diameter

The deviation angle of the tube is

too large

Adjust the tube deviation to 0

The tube support is too large

Adjust the tube support height to

obtain a deviation in degrees below

the horizontal plane

The operator is making the upper

roller advance too rapidly

Reduce the pumping speed (refer to

the relevant operating instructions)

The tube slides or slips in the lathe

screw

The lathe screw fluting is blocked

by metal, worn or flat

Clean or replace the lathe screw

The upper roller is advancing very

slowly

Make the upper roller advance

more rapidly inside the tube

The tube is coming out

Inappropriate direction and height

of the tube support

Vary the direction and height of the

tube support

Rough surface of the steel tube

Polish the surfaces

There is no pressure in the hydraulic

cylinder When actuating the pump

handle nothing happens

Insufficient hydraulic oil

Add hydraulic oil

Dirty oil is blocking the orifice

Replace the hydraulic oil and clean

the circuit

Oil is leaking from the valve

Remove the screw and springGently

hit the small steel ball to make it

come out

The piston advances when actuating

the cylinder handle however recedes

when releasing the handle

Dirty oil is blocking the orifice

Replace the hydraulic oil

Oil is leaking from the valve

Remove the screw and spring

Gently hit the small steel ball to

make it come out

Oil is leaking from another point

Locate the problem and correct

Insufficient hydraulic cylinder pressure

The relief valve spring is broken

Replace the safety valve

MAINTENANCE