3 measuring multiple sdi-12 sensors, Maintenance, Measuring multiple sdi-12 sensors – Campbell Scientific CS451/CS456 Pressure Transducer User Manual

Page 27: 3. sdi-12 commands

CS451/CS456 Submersible Pressure Transducer

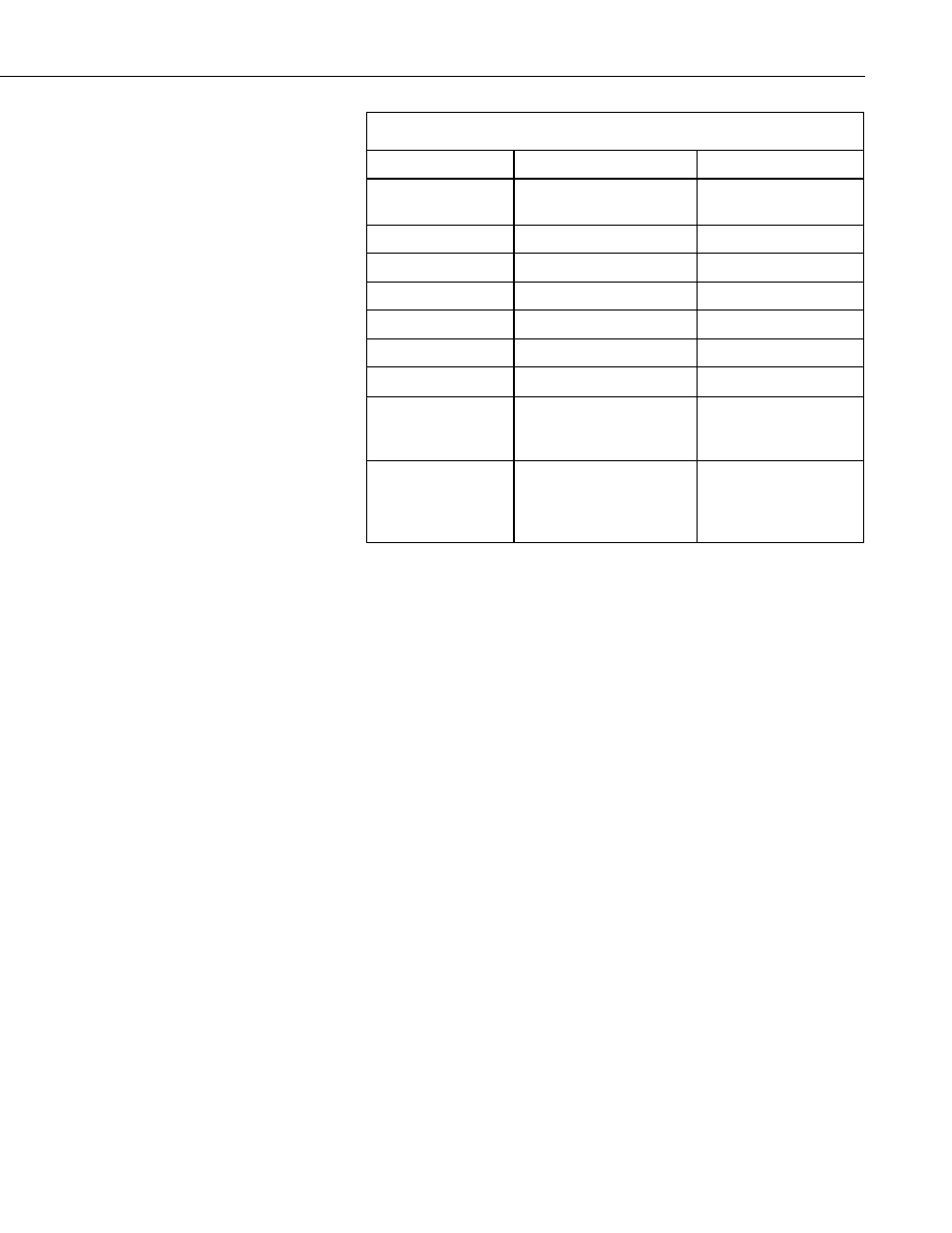

TABLE 8-3. SDI-12 Commands

SDI-12 Command

Command Function

Values Returned

aM!

Configured settings

Pressure/Level,

Temperature

aM1!

PSIG, °C

Pressure, Temperature

aM2!

PSIG, °F

Pressure, Temperature

aM3!

kPa, °C

Pressure, Temperature

aM4!

kPa, °F

Pressure, Temperature

aM5!

Sensor’s Serial Number

Serial Number

aM6!

Ohms, ohms, °C

∆

R, Rb, Temperature

aM7!

Configured settings

(provides data in less than

0.8 seconds)

Pressure/Level

aM8!

Configured settings

(provides average of data

based on user selected

samples)

Pressure/Level,

Temperature

As measurement data is transferred between the probe and datalogger digitally,

there are no offset errors incurred with increasing cable length as seen with

analog sensors. However, with increasing cable length, there is still a point

when digital communications break down, resulting in either no response or

excessive SDI-12 retries and incorrect data due to noise problems. (Using

SDI-12 commands like

aMC!, which adds a CRC check, can significantly

improve incorrect data issues.)

8.3 Measuring Multiple SDI-12 Sensors

Up to ten CS451/CS456 sensors or other SDI-12 sensors can be connected to a

single datalogger control port. Each SDI-12 device must have a unique SDI-12

address of 0 and 9, A to Z, or a to z. See Appendix D, SDI-12 Sensor Support,

for more information.

9. Maintenance

Campbell Scientific recommends that the CS451/CS456 be factory recalibrated

and checked every 24 months. Before a CS451/CS456 sensor is sent to

Campbell Scientific, the customer must get an RMA (returned material

authorization) number, and fill out the Declaration of Hazardous Material and

Decontamination form.

The CS451/CS456 has no user-serviceable parts. Cable can be damaged by

abrasion, rodents, sharp objects, twisting, crimping or crushing, and pulling.

Take care during installation and use to avoid cable damage. If a section of

cable is damaged, it is recommended that you send your sensor back to replace

the bale harness assembly.

17