Safety precautions and guidelines for use – ROHM RPP / RPP-A 2-jaw parallel gripper User Manual

Page 7

Safety Precautions and Guidelines for Use

2-jaw parallel grippers

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 7 of 37

5. Strength of the workpiece to be clamped

In order to ensure reliable gripping of the workpiece with the applied load forces, the clamped material must be

strong enough to withstand the gripping force.

Non-metallic materials such as plastic or rubber, etc. may only be clamped after testing and under particular

observation!

6. Installation and adjustment work

During clamping or alignment movements, etc., short distances are travelled in short times, in some cases with high

forces.

The drive system provided for the gripper actuation must therefore always be switched off during installation and

adjustment work. If the clamping movements are essential during set-up mode, however, then for clamping strokes

longer than 4 mm

- A fixed or temporarily installed workpiece holder must be installed on the device, or

- An independently actuated holding device must be installed,

or

- A workpiece loading aid must be provided,

or

- The set-up operations must be performed in hydraulic, pneumatic or electric jog mode (corresponding control

must be possible!).

The type of this set-up aid depends fundamentally on the machine tool employed and may have to be procured

separately!

The machine owner must ensure that during the whole clamping process, any danger to persons from the

movements of the clamping means is ruled out. For this reason, either 2-hand controls for actuation of the clamping

movement or - even better - corresponding guards must be provided.

7. Tightening and replacement of bolts

If bolts are replaced or loosened, faulty replacement or tightening may result in dangers for persons and materials.

For this reason, the tightening torque recommended by the bolt manufacturer and corresponding to the bolt grade

must always be used for al mounting bolts unless expressly specified otherwise.

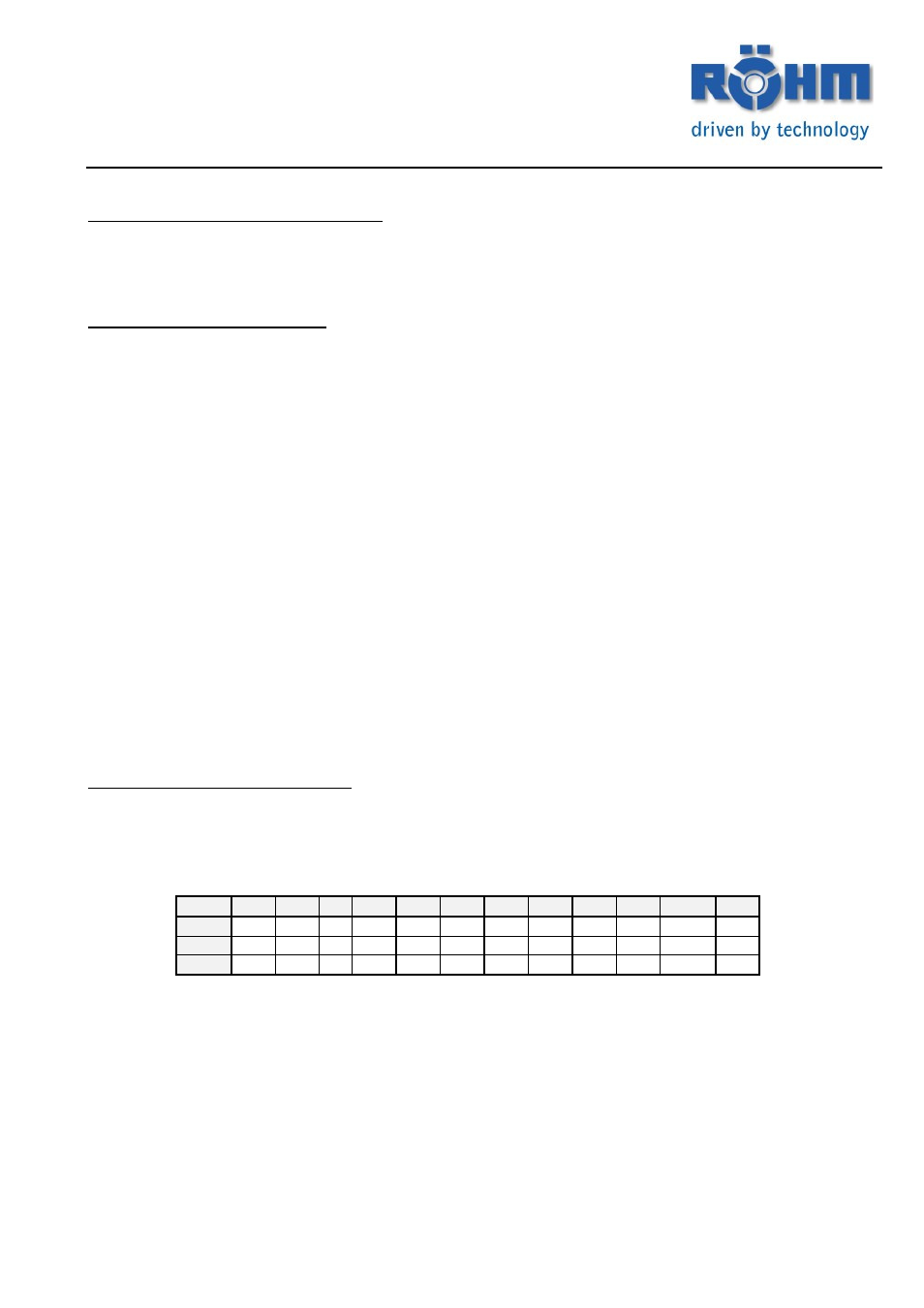

The following tightening torque table applies for all the standard sizes M5 - M24 for grades 8.8, 10.9 and 12.9:

Grade

M5

M6

M8

M10

M12

M14

M16

M18

M20

M22

M24

8.8

5,5

9,5

23 46

80

130 190 270 380 510 670

Nm

10.9

8,1

13

33 65

110 180 270 380 530 720 960

Nm

12.9

9,5

16

39 78

140 220 330 450 640 860 1120 Nm

All figures in Nm

If replacing the original bolts, always use bolt grade 12.9 in case of doubt. The grade 12.9 must always be used for

the mounting bolts of clamping inserts, top jaws, fixed stops, cylinder covers and comparable elements.

All mounting bolts which due to their intended use have to be frequently loosened and tightened again (e.g. due to

tooling work) must be coated with lubricant (grease paste) every six months in the thread area and on the head

contact surface.