Troubleshooting – Ashcroft 4480 - Pneumatic Transmitter User Manual

Page 8

8

GeneraI

Many complaints of faulty transmitter operation have, on

investigation, proven to be due to faulty installation. For this

reason, the following possible causes of trouble should be

considered whenever trouble develops after a new installa-

tion or change in conditions:

Note: To facilitate maintenance and adjustment, the trans-

mitter should be mounted to provide easy access.

a. In critical installations where the pressure tap is at a

different elevation from the transmitter, correction

must be made for liquid “head” or ‘’leg.”

b. Supply air should be filtered and dried.

c. Supply air pressure should be within the specified

ranges.

d. The transmitter should be mounted vertically, to

ensure correct action of components and to maintain

calibration position. If angular mounting is necessary,

the transmitter should be recalibrated in the position

to be used, in order to ensure maximum accuracy.

e. Extremes of ambient temperature should be avoided.

The transmitter should not be subjected to tempera-

ture above 150°F. If process temperatures exceed this

limit, protect the transmitter by means of a siphon or

diaphragm seal.

Note: Since most pressure take-offs are dead end service,

with resultant cooling, it is unlikely that the transmitter

itself will be subjected to temperatures exceeding

150°F, except in extreme cases.

f.

If very low temperatures are encountered, care must

be taken to eliminate any possibility of moisture in the

air lines.

g. For all installations, both the transmitter and the

receiver should be checked together, as a unit, before

operation.

Troubleshooting Procedures

To assist in correcting installation or operational deficiencies,

refer to the following listing of possible troubles and suggest-

ed corrective actions

CAUTION

Dash pot is air actuated. Do not use oil.

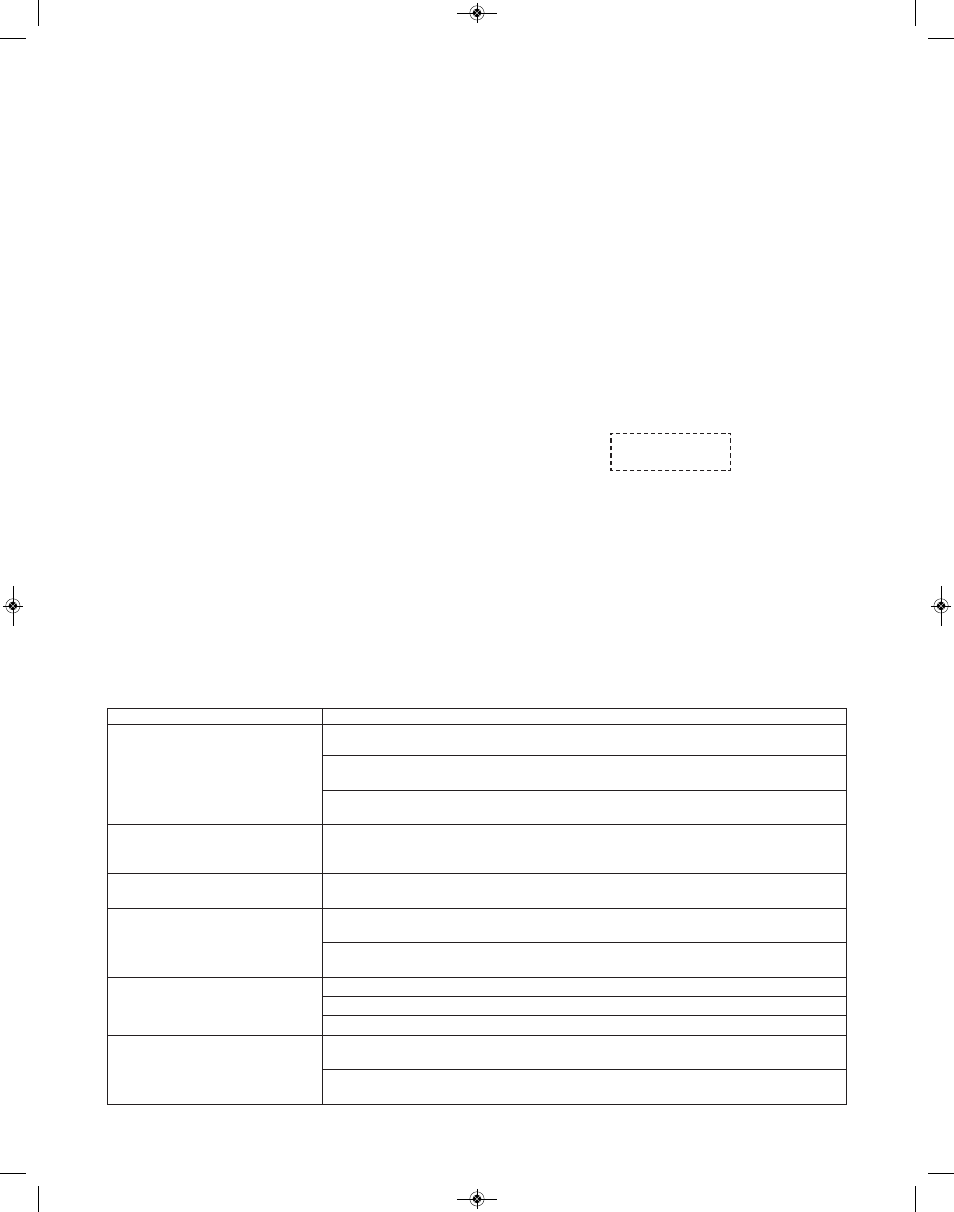

TROUBLE

CORRECTIVE ACTION

1. Pulsation at receiver.

1. Check output line from transmitter to receiver for leaks. Tighten all faulty connections;

repair or replace defective tubing.

2. Remove hex cap on relay and clean seat and seat valve, removing any dirt or foreign

matter which may have entered from air lines.

3. Check for contact between vane and nozzle. Bend vane slightly to center It between

nozzles.

2. Pulsation at input to transmitter.

1. Install pulsation dampener or needle valve slightly ahead of bourdon tube, throttling down

the dampener or valve until pulsation stops but still maintaining an opening in

the line.

3. Vibration on transmitter panel.

1. Brace or shock-mount the transmitter as necessary. Vibration should be eliminated insofar

as possible to prevent loss of calibration of the transmitter.

4. Loss of calibration.

1. Check for and eliminate severe piping strains. (Note: Ashcroft transmitters are designed

and constructed to eliminate normal piping strains.)

2. Check for and eliminate wedging between base casting and plate by screws, nuts, or

other foreign objects.

5. Receiver not corresponding

1. Check for and eliminate leaks in output line.

to transmitter.

2. Check for and eliminate foreign matter in output line.

3. Check to be certain that transmitter is connected to proper receiver.

6. Gross non-linearity in output.

1. Check for interference which may be compressing tubing from relay to input nozzle.

Position tubing to prevent interference.

2. Check for lack of contact between flexure assembly and adjusting disc. Replace flexure

assembly if not in contact with disc.

TROUBLESHOOTING

I&M008-10061-1-01 250-1969-C_I&M008-10061-1/01 250-1969-C 12/20/13 9:09 AM Page 8