Installation – Ashcroft 4480 - Pneumatic Transmitter User Manual

Page 4

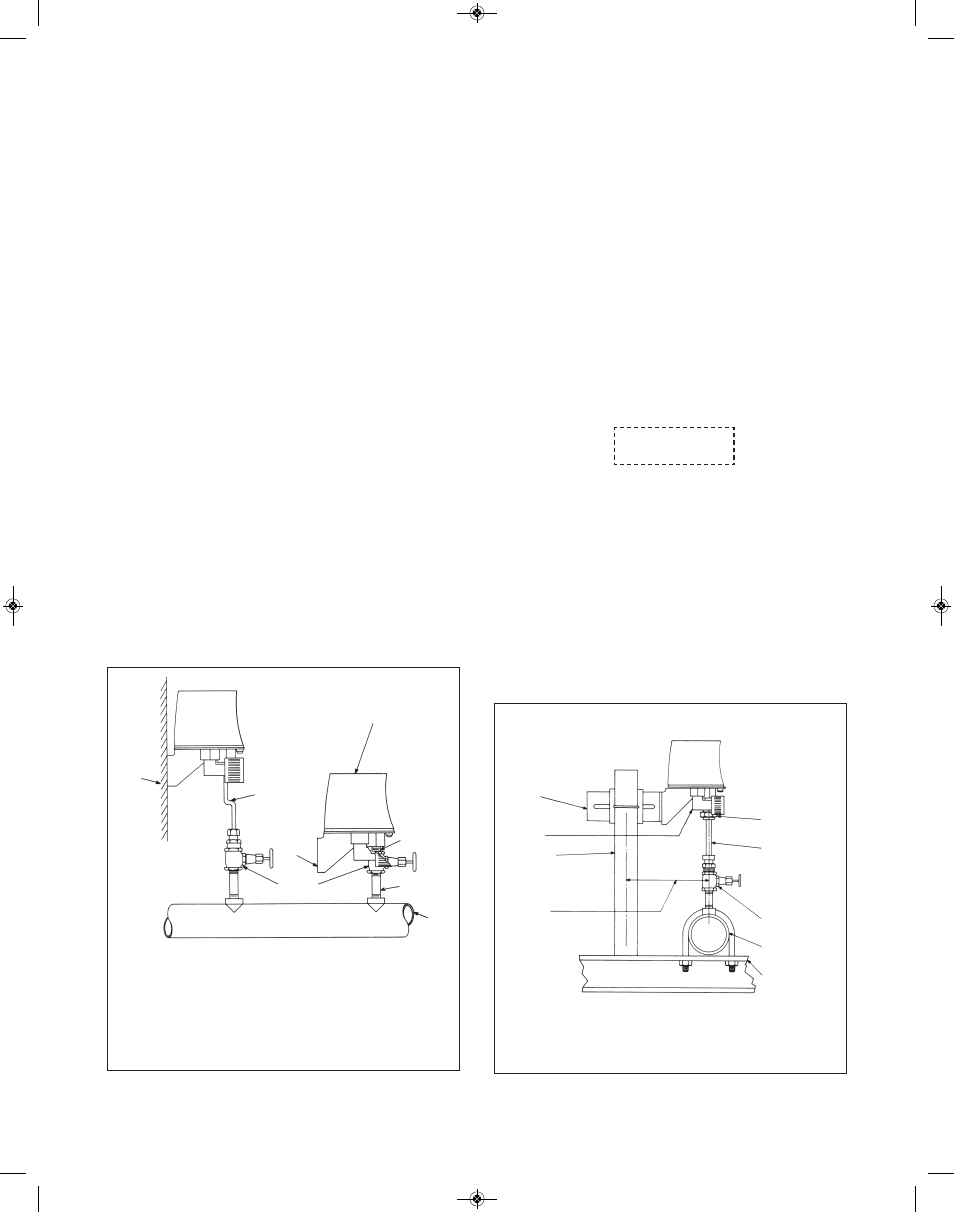

ON STEAM LINES A

SYPHON MUST BE USED.

ON HIGH TEMPERATURE

LINES TWO FEET OF

PIPE SHOULD BE USED

TO INSURE COOLING OF

THE LIQUID. TUBING IS

RECOMMENDED IN

PLACE OF PIPE ABOVE

THE VALVE.

UNION

SHUT-OFF VALVE

ADJUSTABLE

BRACKET

1

⁄

4

NPTF AIR

SUPPLY AND

OUTPUT

CONNECTIONS

2˝ PIPE

SUPPORT POST

CENTER OF SUP-

PORT TO CENTER

OF PIPE LINE

ADJUSTABLE

BETWEEN 5

1

⁄

16

˝

AND 12

13

⁄

16

˝

PIPE SUPPORT

GOOD INSTALLATION PRACTICE DICTATES THAT THE INSTALLATION SHOULD BE FREE OF VIBRATION AND PIP-

ING STRAIN. IF THERE IS VIBRATION IN THE PIPE LINE. THE 2˝ PIPE SUPPORT SHOULD BE MOUNTED ON

SOME INDEPENDENT MEMBER AND THE PRESSURE CONNECTION TO THE TRANSMITTER SHOULD BE TUB-

ING WITH SUFFICIENT FLEXIBILITY TO DAMPEN THE VIBRATION.

PIPE LINE

Figure 5. Pipe-Mounted Pressure Transmitter Installation

4

PIPE LINE

Mounting

Ashcroft pressure transmitters are designed for bracket

mounting (refer to Fig. 4), to ensure free action of all compo-

nents, thereby maintaining accurate calibration. The transmit-

ters may be pipe mounted, wall mounted or stem mounted.

Typical methods of mounting are shown in Figures 4 and 5.

Applicable dimensions are given in the illustrations.

For most trouble-free performance, transmitters should be

mounted vertically. Some loss of accuracy may result from

angular mounting; this may be minimized by recalibration after

mounting.

The transmitters have been designed to withstand severe pul-

sation and vibration. However, in keeping with good instrument

practice, it is recommended that they be installed so as to min-

imize vibration and pulsation.

Ambient Conditions

Ashcroft transmitters are temperature compensated for the

normal range of ambient temperatures. Extremes of ambient

temperature may result in inaccuracies. The transmitter should

not be subjected to temperatures exceeding 150˚F. If the

process temperature will exceed this limit, install a diaphragm

seal or suitable length of pipe to protect the transmitter from

excessive temperatures. If very low temperatures will be

encountered, make certain to eliminate any possibility of mois-

ture in the air lines. Condensation and vaporization of moisture

in air lines cause unpredictable variations in accuracy. For low

ambient temperature installation, a case heating device is rec-

ommended.

STEM MOUNTING NOT

SUITABLE FOR STEAM

OR WHERE THE PIPE

LINE IS VIBRATING OR

VERY HOT

TUBING WITH

BENDS FOR

FLEXIBILITY.

FOR STEAM, A

SYPHON MUST

BE USED WITH

THE TUBING.

WALL OR

COLUMN

BRACKET

MAY BE

REMOVED

SHUT-OFF

VALVES

1

⁄

2

˝

CONNECTION

1

⁄

2

˝ OR

LARGER PIPE

Figure 4. WaIl and Stem-Mounted Pressure Transmitter Installation

NOTES:

PULSATIONS SHOULD BE DAMPENED BY SUITABLE THROTTLING DEVICES.

AS USED ON PRESSURE GAUGES AND LISTED IN THE ASHCROFT GAUGE

ACCESSORY CATALOG

DIAPHRAGM SEALS MAY BE INSTALLED DIRECTLY TO THE TRANSMITTER OR

WITH A CAPILLARY LINE. (BOURDON TUBE ELEMENTS ONLY.

SUPPLY AND OUTPUT AIR CONNECTIONS ARE

1

⁄

4

NPT FEMALE.

DRAIN OR VENT VALVES SHOULD BE INSTALLED ABOVE THE SHUT OFF

VALVE ON HIGH PRESSURE GAS OR DANGEROUS LIQUID INSTALLATIONS.

INSTALLATION

Steam Pressure Measurement

When a transmitter is used for steam pressure measurement,

a siphon filled with water must be installed between the line

and the input element. When the system is subject to occa-

sional vacuum, provide a length of piping which cannot be

emptied by the vacuum. Install a drain cock or plug at the bot-

tom of this leg to provide for cleaning out sediment. Refer to

the Calibration section for the method of zeroing the transmit-

ter to compensate for the “head” effect of introducing the con-

densate water leg.

Pressure Connection

The process pressure connection is the center connection at

the bottom of the transmitter. Always use a wrench on the flats

of the process connection to avoid applying strain to socket

mounting screws and the internal mechanism.

CAUTION

Avoid piping strains in accordance with good installation prac-

tice except in the case of stem mounting, it is preferable to use

flexible tubing for the last length of piping leading to the

transmitter.

I&M008-10061-1-01 250-1969-C_I&M008-10061-1/01 250-1969-C 12/20/13 9:09 AM Page 4