Dake Model Zip 28 User Manual

Page 6

6

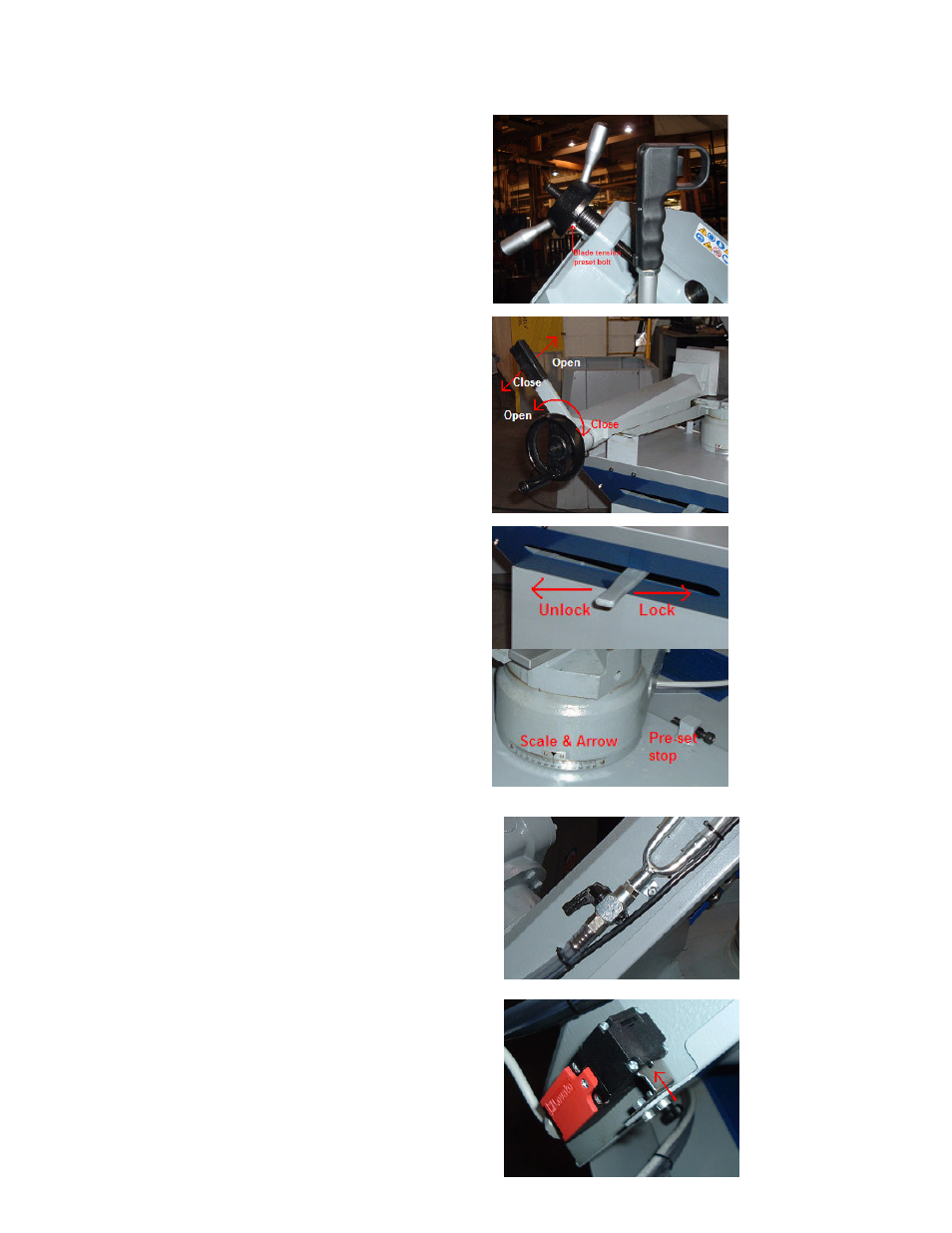

C.

Blade tensioning handle. Mechanical

Blade tensioning handle is turned clockwise

To tighten blade; Handle will hit preset bolt

At the proper tension for the blade size.

NOTE: If different size blade is used, length or

Thickness this bolt will need to be re-calibrated

Using a blade pressure gauge to achieve proper

Preset tension.

D.

Quick Release Vise. Using the handle wheel

Adjustment of the material can be made by

Opening or closing the vise up to the material.

Once the vise jaws come with-in a 1/16 – 1/8”

Of the material the quick release cam handle

Can be used to open or close the vise to the

Material for fast action.

E.

Head Lock Lever. The head lock lever

When released allows the rotation of the

Cutting head up to 60

°

for mitering. Move

The lever to the left to unlock the head and

Right to lock it at any angle. For angle set

Up align arrow to the angle required on

The scale at the bottom of the rotation

Point of the vise. There is preset

Adjustable stops at 90

°

(0

°

) and 60

°

These can be calibrated by turning the

Stop bolts in or out to get correct angle.

F.

Coolant Flow Control. This valve is located on the

Bandsaw cutting head on the top of the casting

Towards the rear of the saw head. This valve controls

The amount of coolant distributed during cutting.

When adjusting be sure coolant flow is sufficient to

Both guides.

G.

Interlock. This interlock is mounted on the rear of

The cutting head and will disable the saw when the

Blade cover is open. This prevent accidental starting

Or running of the machine during blade changes.