Dake Model Zip 28 User Manual

Page 5

5

3. Stock stop installation can be done at any time. This is used to deadhead your material against

for cutting repeat lengths. This can be removed if not being used. The stock stop screws into the

vise base on the right hand side of the vise. (Figure 7) The stop is measured using a tape or

template from the blade to the face of the stock stop. It is adjusted by loosening the pinch bolts

on the stop block.

Figure 7

4. Add coolant. Mix the coolant as outlined in the instructions furnished with the coolant

concentrate. Usually mixed 10:1. Use only a high quality water soluble coolant. NOTE: Do not

use cutting oils!

Premix the coolant and pour small amounts directly into the blue filter screen on the back of the

saw. (Approx. 3 gallons) Do not over fill because on the right rear side there is a weep hole that

excess coolant will flow out of onto the floor. Slowly add coolant and check in the weep hole

using a small wire or pencil and stop filling when you are about ¼” from the weep hole. (Figure 8)

Figure 8

2. Component features, functions and adjustments:

A.

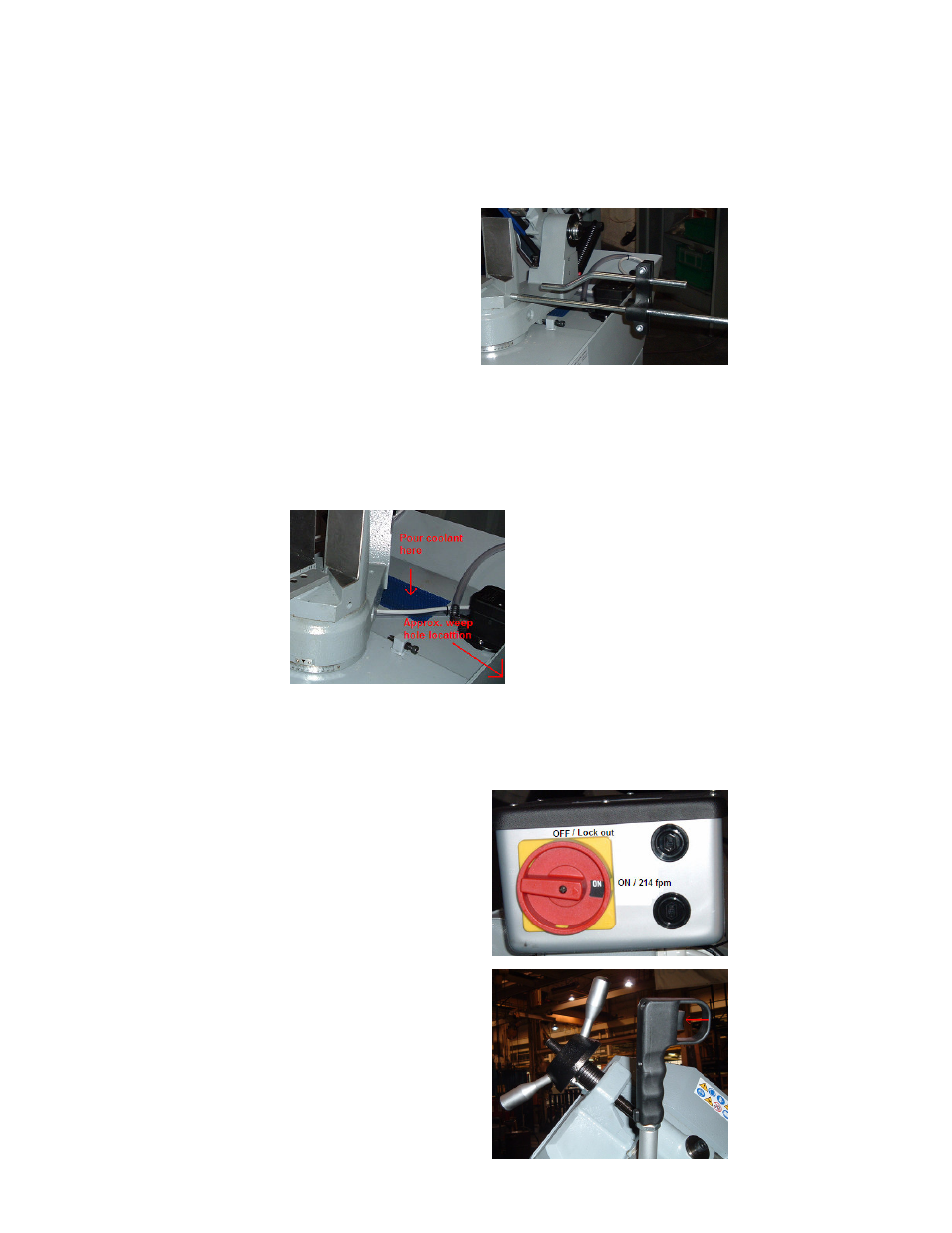

Electrical Box. Off with lock out / on @ 214 fpm.

NOTE: With switch on the motor does not run!

B.

Trigger Switch. Dead man style safety switch.

Trigger is pulled to make motor run.

(Both blade and coolant motors)