Dake Model Zip 28 User Manual

Page 12

12

8. Blades:

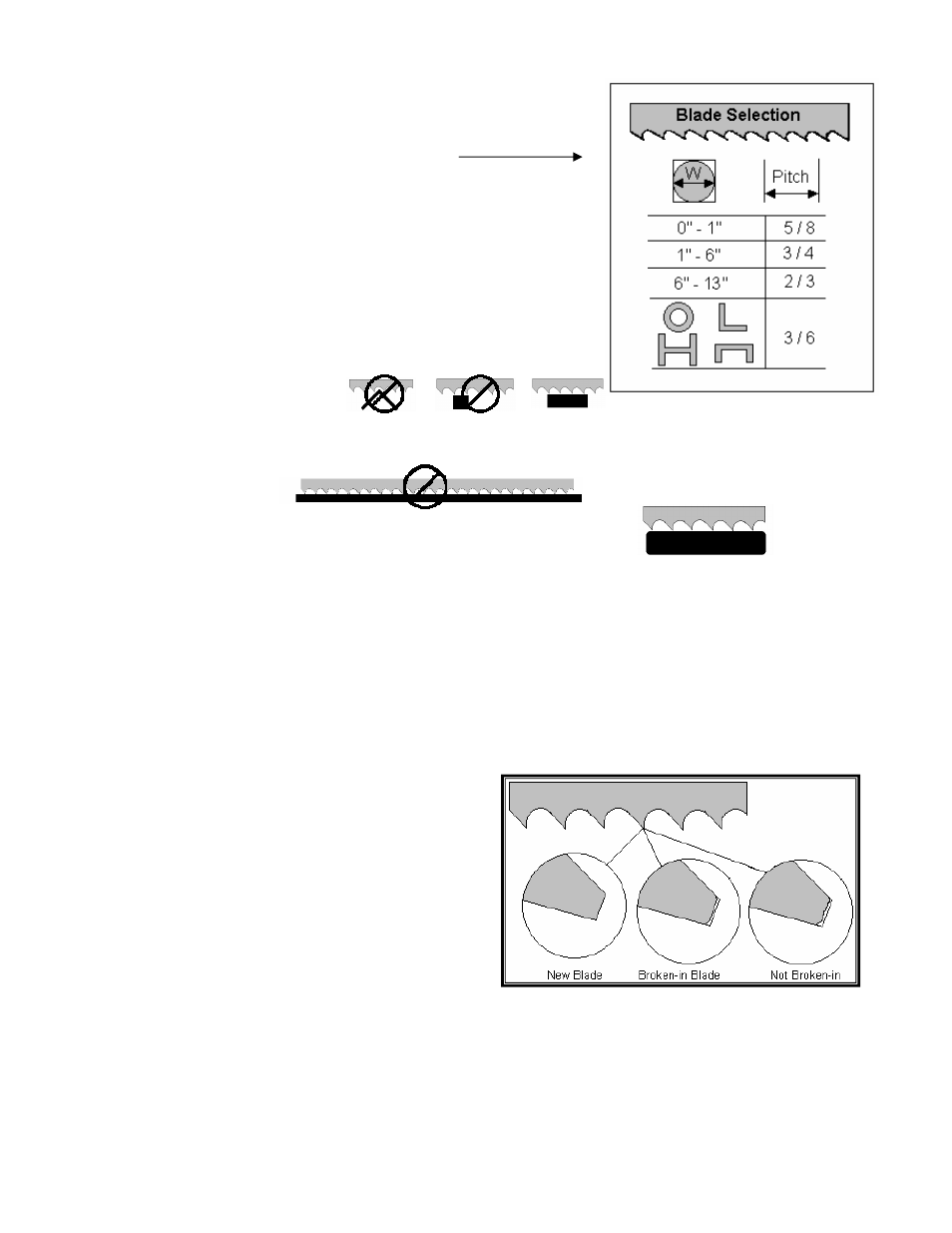

8.1 Simplified selection chart at right.

1. Rules of thumb for blade selection

Four important numbers to keep in mind are the

Rule of thumb numbers. These numbers are

3, 6, 12 and 24:

Number 3: Represents the minimum

Number of teeth you want working at one

time. If the blade is too coarse for the work,

The teeth can straddle the work; this will strip

Teeth from the blade.

Number 24: The maximum number of teeth you would want in the cut at one time. Too fine a

tooth blade will clog with chips again resulting in stripped teeth.

Number 6 to 12: The ideal number of teeth working at one time.

8.2 Blade breaks in:

1. It is recommended that the blade manufactures break procedure is followed.

Proper blade break-in is as important to good blade life as choosing the right blade. The best

analogy I have heard for blade break-in is the pencil story. If you sharpen a pencil to a nice

sharp point and attempt to write with it, the lead breaks off because it is too sharp to glide

over the paper. If you take the same pencil with the same sharp point and lightly rub it over

the paper you hone or soften the point, resulting in a pencil that can be used for a long period

of time.

The same is true with a bandsaw blade.

When it is new it has very sharp point over

the length of the blade that will tear the

material, chatter and chip or round off the

teeth in a hurry. Breaking in the blade

allows for tips of the teeth to be honed into

a usable tooth that produces good cuts and

longevity.

Blade break-in will vary depending on the

type of material you are cutting. Softer

materials such as carbon steel or aluminum

will require a longer break-in cycle than that of harder materials. Structurals and pipe will

require a longer break-in period because the actual square inches are reduced due to the

interruptions of the material. From the charts listed earlier you can determine if the break-in

will be for softer or harder material

A simplified rule of thumb break-in procedure that applies to most applications:

1. Set blade speed to normal cutting fpm.