Dake Model Zip 28 User Manual

Page 11

11

7. Maintenance and routine adjustments.

7.1 Maintenance Daily:

1. Top off coolant as needed.

2. General cleaning of machine. Clean chips and debris from machine.

3. Check condition of the saw blade.

4. Check all guards and interlocks.

7.2 Weekly Maintenance:

1. Clean all chips from coolant filter cover. (Blue cover on top rear of machine)

2. Clean band wheels.

7.3 Monthly Maintenance:

1. Check tightness of band wheel bolts.

2. Check guides for wear debris for adjustment.

3. Check guards and interlocks.

4. Replace coolant. Clean coolant reservoir and pump pick up screen.

NOTE: Gear box is maintenance free.

7.4 Routine Adjustments:

1. If slop develops in vise, tighten vise slide screws.

2. Calibration of guides or preset tensioning bolt. (See 6.1 –3)

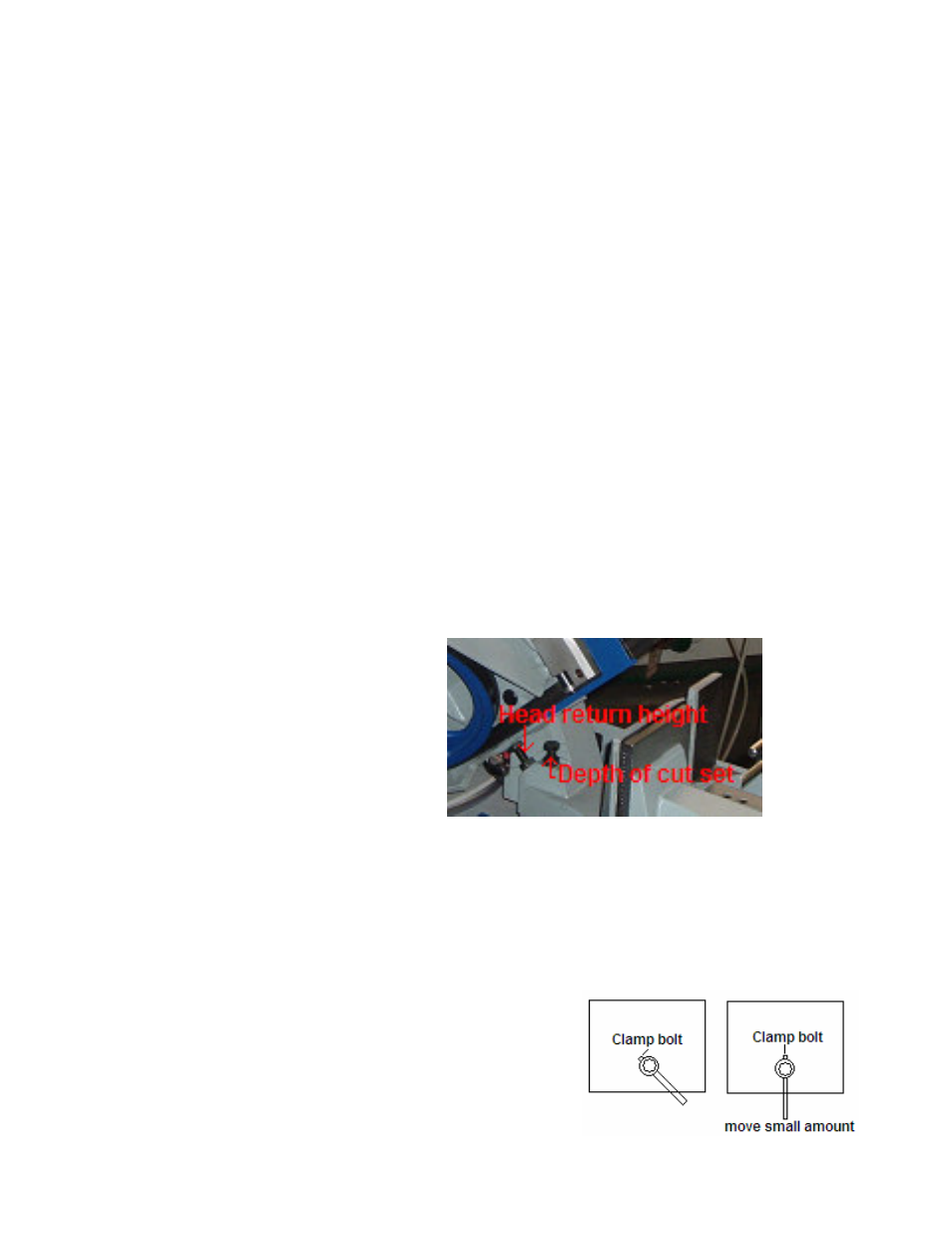

3. Head height and depth of cut.

Per photo on the right there are two

Adjusting screws with lock nuts. One

Bolt in the back is for setting max.

Height of the head return. This can

Be set so the head does not go up

As high, if material being cut is

Smaller diameters. The other bolt

In the front limits the depth of cut,

And can be set to prevent cutting

Into the vise casting. Simply loosen

Lock nuts adjust bolts to where you need them and tighten lock nuts down.

4. Angle stop calibration see paragraph E in section 2.

5. If head lock lever is loose and will not tighten head in position remove from access panel

(As you did during mounting of saw to base) set the lever in the tighten position. With the

lever all the way to the right loosen the large clamp bolt on the locking lever casting. Drop

handle down slightly on the shaft and move toward the left a very small amount. (A

couple of teeth on the shaft are sufficient), push the lever back up onto the shaft and

tighten clamp bolt. Reinstall access panel.