Transport wheels, Auto-cable fold, Cables – Summers 4-Rank Superweeder User Manual

Page 55

SECTION 3 - SUPERHARROW 2650

3-11

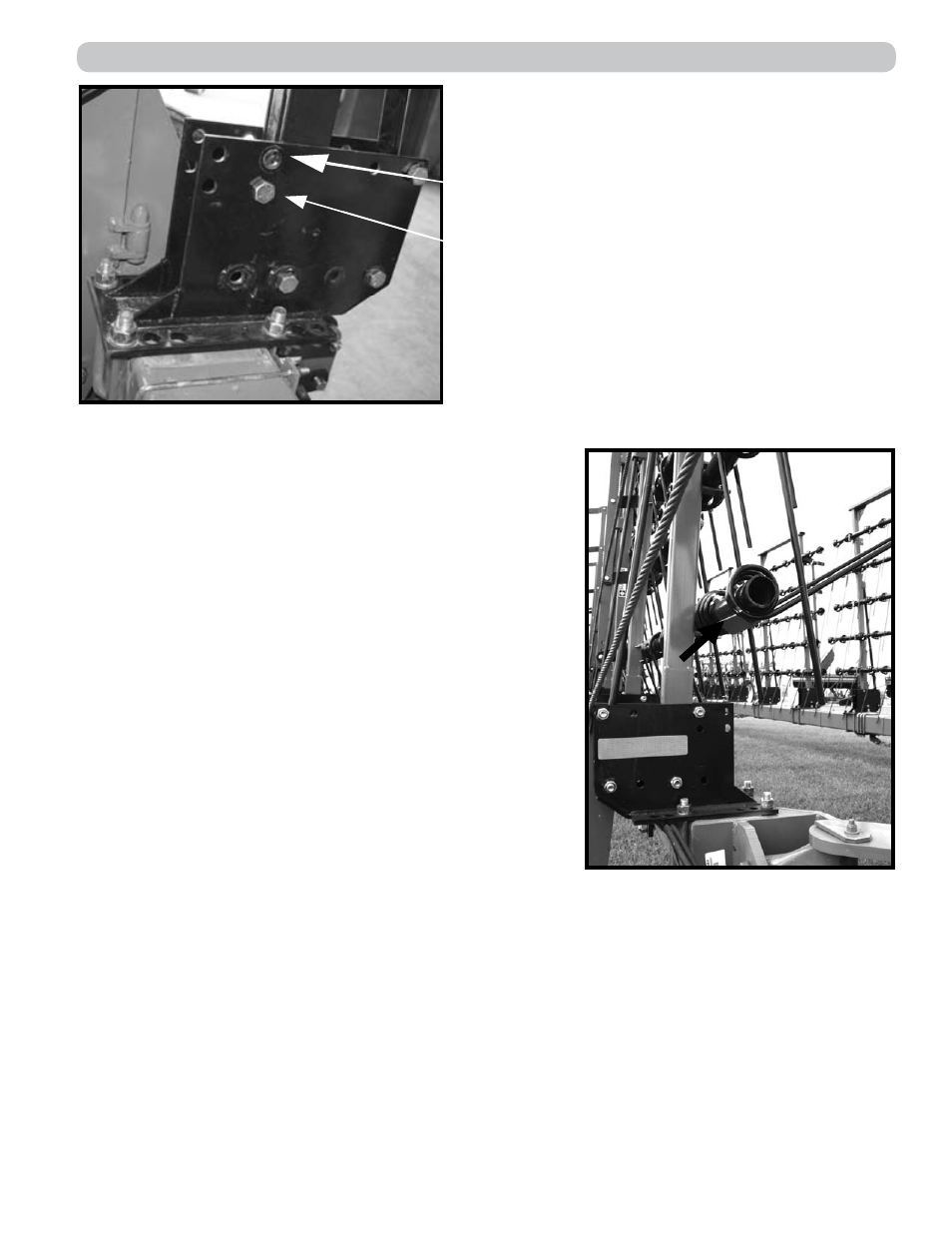

The two front teeth on the wing (closest to knuckles) must be secured

with PN 8HD6150 (ANGLE, tooth stop) and 1/2” X 3-3/4” cap screws as

shown in Fig. 9. This prevents interference in transport position.

TRANSPORT WHEELS

Locate transport wheel assemblies over end harrow section on 56 ft. ma-

chine with pivot tube in higher position. Install between end section and

second section on 72 ft. and 88 ft., both with pivot tube in lower position.

Secure with 7/8” U-bolts and hardware.

Transport axle “toe-in” can be adjusted with the outside stop set bolt

(8X0665, Page 3-5). Adjust inside stop bolt 3/8” away from pivot plate

when resting on outside stop bolt. This adjustment will allow transport

wheel to pivot inward while unfolding. Double lock stop bolts with 3/4”

jam nuts provided.

AUTO-CABLE FOLD

Mount Auto-Fold pivot brackets ahead of welded stop. Do not fully tighten

U-bolts. Attach left and right cable fold arms to pivot brackets with 1-1/4”

X 14” pins and hardware.

Adjust pivot brackets to provide clearance between the cable fold arm

bottom guide and hitch tube. This adjustment is made with 3/4” X 2-1/4”

bolts (8X0112, Page 3-7). This adjustment will allow cable fold arms to pivot freely into transport position. Fully tighten

mounting U-bolts after adjustment is made.

Attach tension springs with 3/4” eye bolts and lock nuts. Tighten eye bolts until spring coils begin to separate.

CABLES

Install cable brackets and cable assemblies. Adjust cables so wings lead the center by 2 degrees. Tighten attachment

U-bolt. Recheck tightness after first hour of field use. Install rear cables as shown on page 3-13 through 3-15. 72’ and 88’

SuperHarrow 2650 ONLY: Install Cable Guides as shown on next page.

Wing Section Lower Stop Bolt Location

Center Section Stop Bolt Location

(shown installed)

Fig. 8

Fig. 9: ANGLE, tooth stop