Transport wheels, Auto-cable fold, Cables – Summers 4-Rank Superweeder User Manual

Page 23: Hydraulic tine angle

Fig. 8

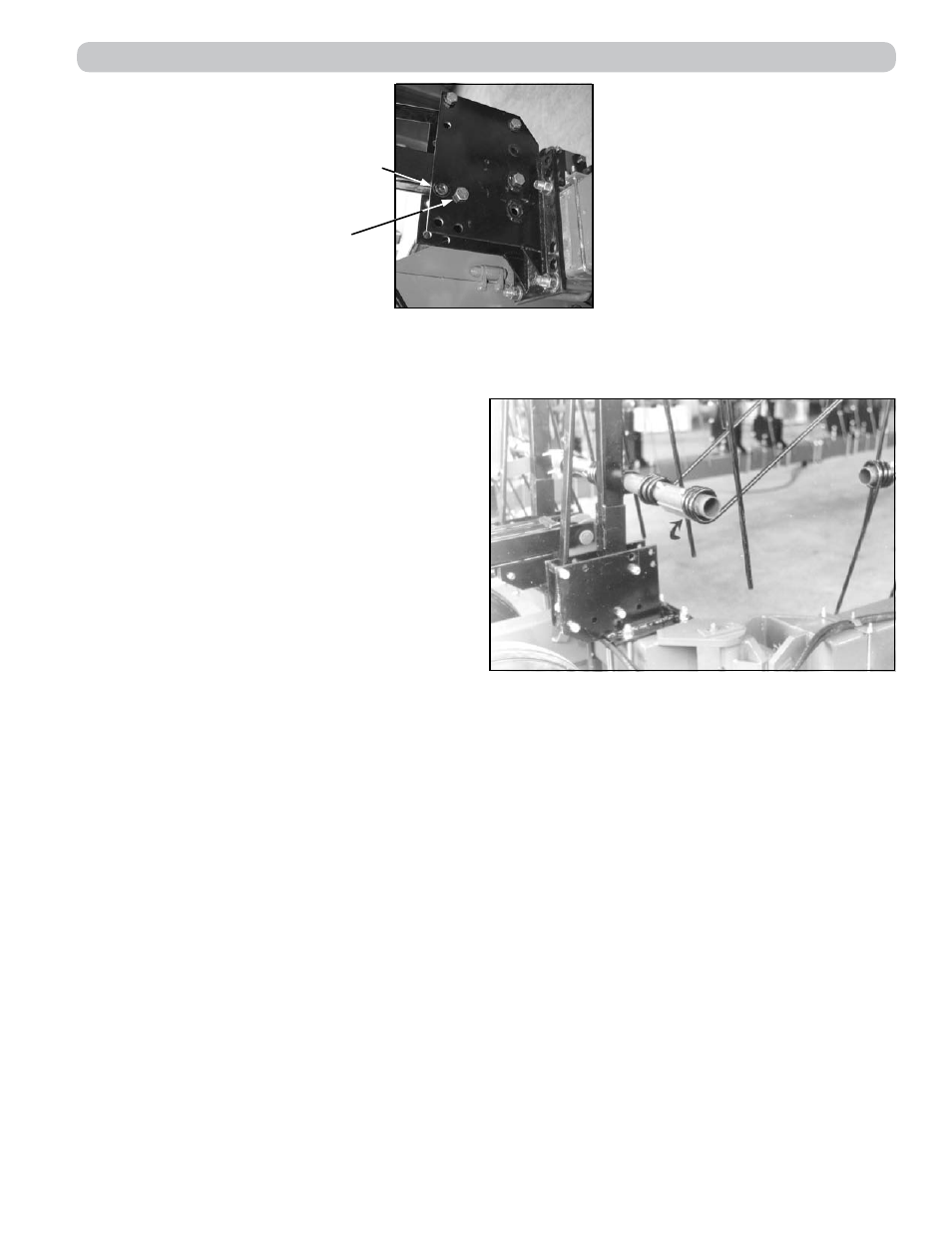

The two front outside teeth on the center section (closest to knuckles) must be secured with PN

8HD6150 (ANGLE, tooth stop) and 1/2” X 3-3/4” cap screws as shown in Fig. 9. This prevents

interference in transport position.

TRANSPORT WHEELS

Locate transport wheel assemblies over end har-

row section on 36 through 60 ft. machines with

pivot tube in higher position. Install between end

section and second section on 72 ft. and over sec-

ond section on 84 ft., both with pivot tube in lower

position. Secure with 7/8” U-bolts and hardware.

Transport axle “toe-in” can be adjusted with the

outside stop set bolt (8X0665, Page 2-8). Adjust

inside stop bolt 3/8” away from pivot plate when

resting on outside stop bolt. This adjustment will

allow transport wheel to pivot inward while unfold-

ing. Double lock stop bolts with 3/4” jam nuts provided.

AUTO-CABLE FOLD

Mount Auto-Fold pivot brackets ahead of welded stop. Do not fully tighten U-bolts. Attach left and

right cable fold arms to pivot brackets with 1-1/4” X 14” pins and hardware.

Adjust pivot brackets to provide clearance between the cable fold arm bottom guide and hitch tube.

This adjustment is made with 3/4” X 2-1/4” bolts (8X0112, Page 2-8). This adjustment will allow cable

fold arms to pivot freely into transport position. Fully tighten mounting U-bolts after adjustment is made.

Attach tension springs with 3/4” eye bolts and lock nuts. Tighten eye bolts until spring coils begin to

separate.

CABLES

Install cable brackets and cable assemblies. Adjust cables so wings slightly lead the center. Tighten

attachment U-bolt. Recheck tightness after first hour of field use. Install rear cables as shown on

page 2-14. 72’ and 84’ SuperHarrow Plus ONLY: Install Cable Guides as shown on Page 2-15.

HYDRAULIC TINE ANGLE OPTION:

See following Set-Up Instructions and parts breakdown pages 2-16 through 2-24 and layout on

Wing Section Lower Stop Bolt Location

Center Section Stop Bolt Location

(shown installed)

Fig. 9: ANGLE, tooth stop

SECTION 2 - SUPERHARROW PLUS

2-11