Chapter 3: wiring, 1 wiring connections, Power supply/ground connections – AMETEK 957 SSI Brik User Manual

Page 7: Cable connectors

7

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

FACTORY AUTOMATION

®

Chapter 3: Wiring

Once the LDT has been installed, wiring connections can

be made. There are two groups of connections you will

need to make. They are as follows:

• Power Supply Connections (including ground and

shield)

• LDT Input/Output Connections

Power Supply/Ground Connections

The 957SSI is available with many different connector/wir-

ing options. Refer to part numbering on unit in question

for proper wiring. See Section 3.5 for part numbering and

figures 3.3 - 3.8 for wiring details.

The 957SSI standard cable is a 6 Pin, 12mm, cordset.

It has 6 conductors of 24ga, with an aluminum/poly-

ester/aluminum foil with drain wire plus an over-

all braid of tinned copper shield. Cable O.D. is .23

(5.7mm ). To reduce electrical noise, the shield must be

properly used. Connect the cable’s shield to the controller

system GND.

Always observe proper grounding techniques such as sin-

gle point grounding and isolating high voltage (i.e. 120/240

VAC) from low voltage (7-30 VDC cables). Whenever pos-

sible, this cable should be run in conduit by itself. The

power supply common, the cable shield and a good earth

ground should be connected together at the location of

the power supply common. See figure 3-1 Power Supply

Wiring.

WARNING Do not route the Brik™

output cable near high voltage

sources.

3.1 Wiring Connections

UNIPOLAR

Single ended

power supply

+7 to +30 VDC

+ COM

Power+

Common

Figure 3-1 Power Supply Wiring

In order for the 957SSI to operate properly, the LDT’s ex-

ternal power supply must provide a voltage between +7

to +30 VDC. The power supply must be rated at 150mA

minimum. The power supply should provide less than 1%

ripple and 10% regulations. (The power supply should be

dedicated to the LDT to prevent noise from external loads

from affecting the position readings.)

Cable lengths

AMETEK recommends that the maximum cable length be

10 meters. Cables greater than 33 feet are available; how-

ever, proper care must be taken during installation.

Any extension to the existing cabling should be mount-

ed in a junction box free of any other cabling, the cable

should be a twisted shielded pair with a braided shield.

The shield should pass straight thru this enclosure and not

tied to ground. When grounding the LDT, a single earth

ground should be connected to the power supply common.

The LDT power supply common should be connected to

the power supply common (-) terminal. The LDT’s shield

should be tied to the earth ground at the power supply.

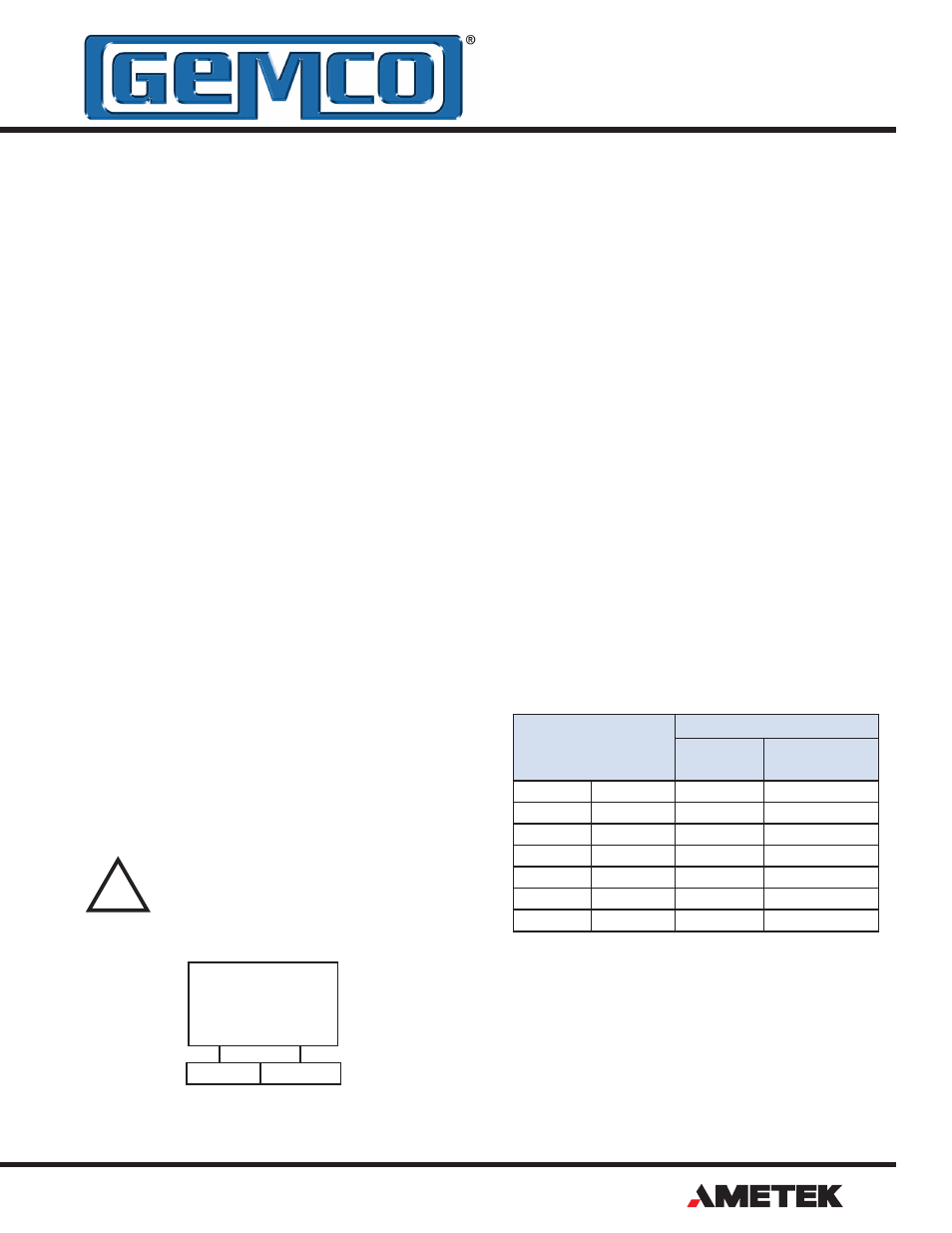

Cable length limitations are based on SSI clock fre-

quencies. Apply good industry practices for long cable

runs - keep cable away from high power AC lines and all

motor drive cables.

Cable Connectors

The 975SSI is available with various cable connection op-

tions. See figure 3-2 for standard options. Should a differ-

ent connector be required for an application, please con-

tact the factory at 800-635-0289.

!

Note: Minimum SSI clock frequency rate is 70 kHz.

Cable Length

Controller Data Sampling

Falling

Edge

Rising Edge

6 ft

1.83 m

750 kHz

1500 kHz

30 ft

9.14 m

650 kHz

1300 kHz

100 ft

30.48 m

500 kHz

1000 kHz

150 ft

45.72 m

400 kHz

800 kHz

300 ft

91.44 m

270 kHz

540 kHz

600 ft

182.88 m

160 kHz

320 kHz

1200 ft

365.76 m

90 kHz

180 kHz