4 specifications, Cable specifications, Specifications – AMETEK 957 SSI Brik User Manual

Page 17

17

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

FACTORY AUTOMATION

®

If your LDT is not operating properly, the LDT’s cable may

have an open or short, or the power supply is not supply-

ing sufficient power. To verify this, perform the following

steps:

1. Turn the power supply off.

2. Remove the mating connector from the LDT.

3. Turn the power supply on.

4. Using a digital voltmeter, check from the Power Sup-

ply Common to the Power Supply + on the mating

end of the cable for a level between +7 and +30

VDC.

If reading is between 7 and 30 VDC, turn power supply off

and go to step 7. If reading is below 7 VDC, either your

power supply is not providing enough power or the LDT’s

cable possibly has a short/open. Readings of no voltage

or minimal voltage (less than 5 volts) may be due to short/

open in the cable. If reading is

NOT between 7 and 30

VDC, go to step 5. If reading is above 30 VDC, adjust pow-

er supply or replace.

5. Turn the power supply off.

6. Check the continuity of the individual wires of the

cable between the power supply and the LDT. Check

for continuity from one end of the cable to the other.

Also verify that no shorts exist between pins.

7. Reconnect the mating connector to the LDT.

8. Turn power supply on.

9. Using a digital voltmeter, check the power supply’s

“+” and “-” terminals for a voltage between 7 and 30

VDC.

Low voltage readings may indicate a power supply with a

wattage (current) rating that is too low. (Each LDT requires

approximately 1.3 watts). If the cabling checks out in step

6 and your voltage is below 7 VDC, check your power sup-

ply current rating. If voltage is between 7 to 30 VDC and

the LDT is still inoperative, contact factory.

* See Section 3.4: Specifications for more information on

power consumption.

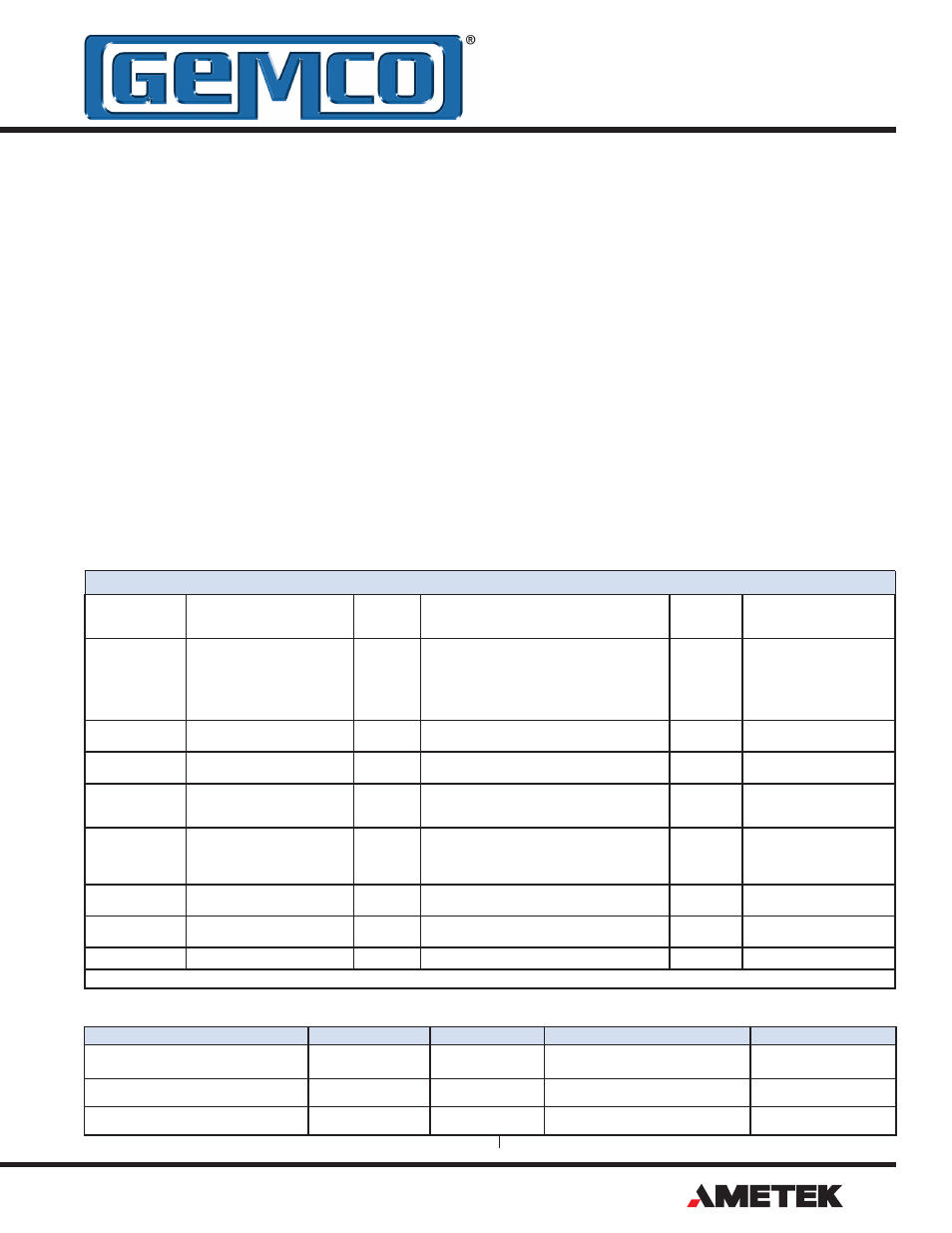

3.4 Specifications

Cable Specifications

Specifications

Connector Interface

6 Pin 12mm

Integral cable ass'y, 7 Pin or 8 Pin

DIN

Shock

1000 Gs

IEC 60068-2-27

Output Type

24, 25 or 26 Bit, Binary or Gray

Code (optional parity and error

bit), Position Updates

Displacement

1” to 180"

Vibration

30 Gs

IEC 60068-2-6

Resolution

English or Metric Units

Metric: 1, 5, 10, 20 micron (5

micron standard)

English: .00005", .0001", .0005",

.001"

Consult Factory for Others.

Dead Band

2.65" (67.31 mm) standard

Update Time

Measuring Length

300 750 1000 2000 5000mm

Measurements/sec. 4.0 2.4 2.0

1.1

0.5k

Hysteresis

0.008”

Null Zone

2.00" (50.8 mm) standard

Approvals

CE (EMC)

Non-linearity

< 0.01% or +/- 0.005”, whichever

is greater, (+/- 0.003" Typical)

Enclosure Rating

IP67, IEC 600529

Input Voltage

7 to 30 VDC

Diagnostics

Tri-Color LED beside connector/

cable exit, See 'LED Output Sum-

mary Table' on page 13

Measured Variables

Single Magnet Displacement, Consult

Factory for Velocity or Differential

Operation

Current

Draw

1.3 watts, (53mA at 24 VDC) typical*

Operating

Temperature

-40° to 185° F ( -40° to 85° C)

Interface Specifica-

tions Input SSI Clock

RS-422, 470 Ohm termination

resistance

Storage

Temperature

-40° to 221° F

(-40° to 105° C)

Output Data Pulse

Resistance

RS-422, 2.0V min. @ 100 Ohm

termination

Repeatability

Equal to Output Resolution

SSI Clock Frequency

Minimum 70 kHz Maximum 150 kHz

NOTE: Specifications subject to change and are based on a typical 48” stroke. *1.3 watt typical at 1ms interrogation time. Faster interrogation times increase power consumption.

Cable Type

Gauge

Jacket

Temp

Bend Radius

Connector Options "S", "M", "B", "C"

24

PVC

-50° to 105° C

Moving Applications - 2.36"

Fixed applications - 1.18"

High Temp Integral Cable "H" option

22

Teflon

-70° to 200° C

Moving Applications - 4.6"

Fixed applications - 2.3"

Connector Option "E"

22

Polyurethane

-50° to 105° C

Moving Applications - 2.3"

Fixed applications - 1.2"