0 troubleshooting table, Operating and installation instructions cona, S - ball float steam traps – ARI Armaturen CONA S PN40 EN User Manual

Page 13

Rev. 0040805002 1404

Page 13

Operating and installation instructions

CONA

®

S - Ball float steam traps

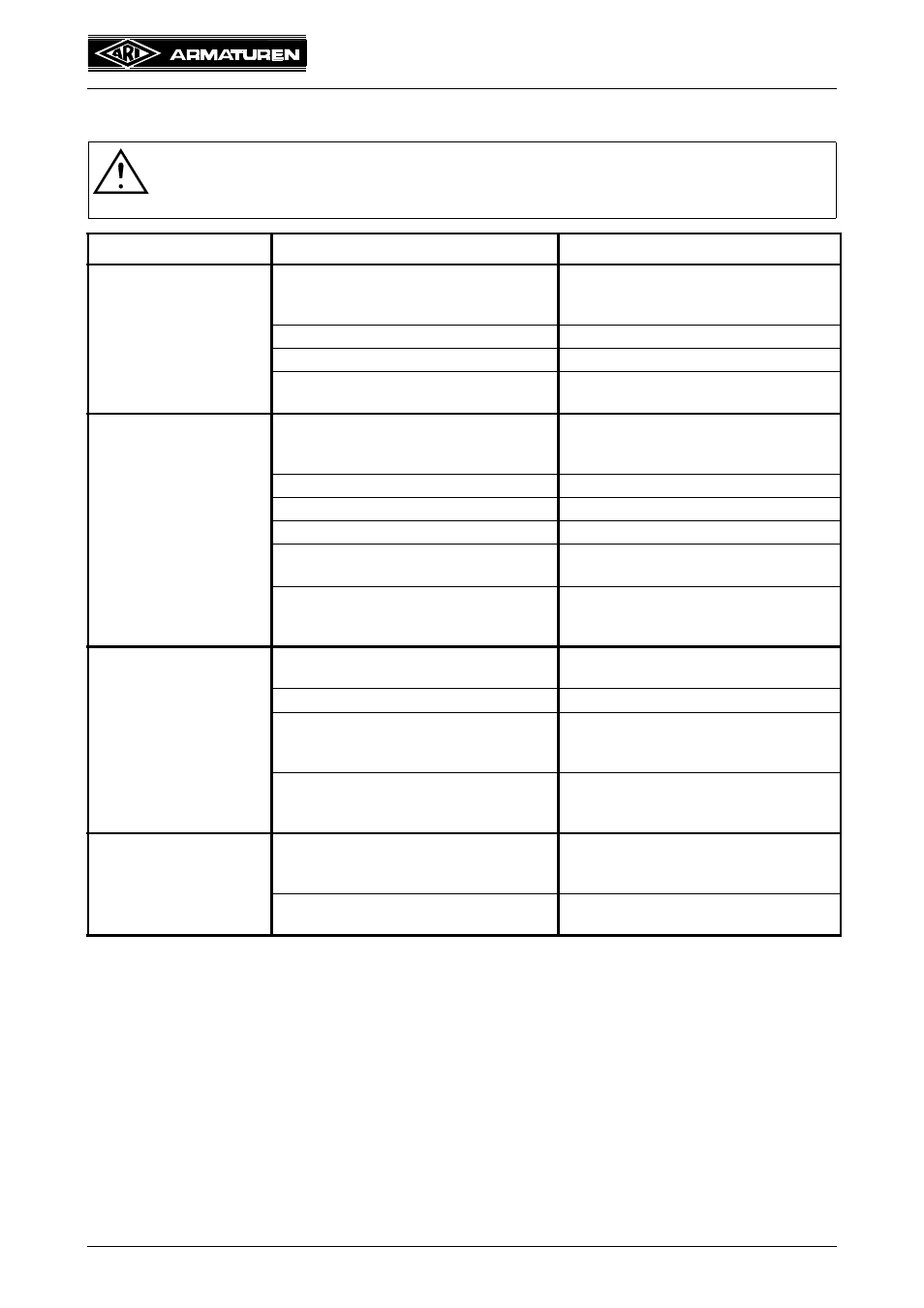

9.0 Troubleshooting table

ATTENTION !

- refer to item 10.0 and 11.0 prior to dismantling and repair work !

- refer to item 6.0 before restarting the plant !

Fault

Possible cause

Corrective measures

No flow

Installed in wrong flow direction

Fit valve in direction of flow arrow.

Note installation position; refer to item

5.5.1!

Flange covers not removed

Remove flange covers

Ball float (Pos. 24.16) defective

Check lifting force; refer to item 7.1

Condensate cannot get to steam trap

due to bad pipeline routing.

Note installation position;

refer to item 7.4

Reduced flow

Wrong installation position

Correct installation position; refer to item

5.5.1! Correct installation position; refer

to item 7.2

Strainer clogged (Pos. 2)

Clean strainer; refer to item 7.1

Piping system clogged

Check piping system

Wrong controller size choosen

Correct selection acc. to flow diagram

Changed upstream pressure or back

pressure operating conditions

Correct selection acc. to flow diagram

Ball float (Pos. 24.16) prevented from

swivelling, particularly in horizontal instal-

lation position

Use pressure compensation line option;

refer to item 7.4

No closure, or internal

leakage

Controller clogged

Clean strainer and controller;

refer to item 7.1

Controller worn out

Change controller; refer to item 7.1

Controller incorrectly screwed into body Check seal face between body and con-

troller, tighten controller correctly; refer

to item 7.5

Controller operated above safe operating

pressure

Observe operating limits as per data

sheet, i.e. possibly select different con-

troller

External leakage

Hood (Pos. 16) not properly tightened

with hex. nut (Pos. 28) or cheese-head

screw (Pos. 27)

Tighten; refer to item 7.5

Flat gasket (Pos. 17) defective.

Replace sealing;

see 7.1