2 requirements at the place of installation, 3 installation instructions concerning actuators – ARI Armaturen STEVI 451 EN User Manual

Page 8

Page 8

Rev. 0040306000 0410

Operating and installation instructions

3-way control valves - STEVI

®

450 / 451

5.2 Requirements at the place of installation

The place of installation should be easily accessible and provide ample space for

maintenance and removing the actuator. Stop valves should be installed before and behind

the control valve to enable maintenance working without draining the piping system. The

valve should preferably installed vertically with the actuator at the top. Inclined or horizontal

installation without supports is permissible only with light actuators.

For this installation position, the two distance columns (or joke) have to be above each

other in the vertical plane.

Safe actuator weights for a horizontal installation position with reference to the stem,

without structural support, are as follows:

20 kg for DN 15 - 32

25 kg for DN 40 - 65

35 kg for DN 80-100

40 kg for DN125-150

55 kg for DN125v-150v

The pipes must be lagged to protect the actuators from excessive heat. Sufficient space

must be left for the maintenance of the stem packing.

To ensure that the control valves function correctly, the pipe run should be straight for at

least 2 x DN upstream and 6 x DN downstream of the valve.

5.3 Installation instructions concerning actuators

Normally, control valves are supplied complete with actuator fitted.

It is not permitted to mantle / dismantle actuators with valves operating at service conditions

(temperature and pressure) the actuators must be assembled as describe in the operating

instructions during conversion and maintenance.

During assembly work, the plug is not be turned on its seatring at closing pressure.

When retrofitting actuators, the maximum permissible force for valve actuation must be

taken into account:

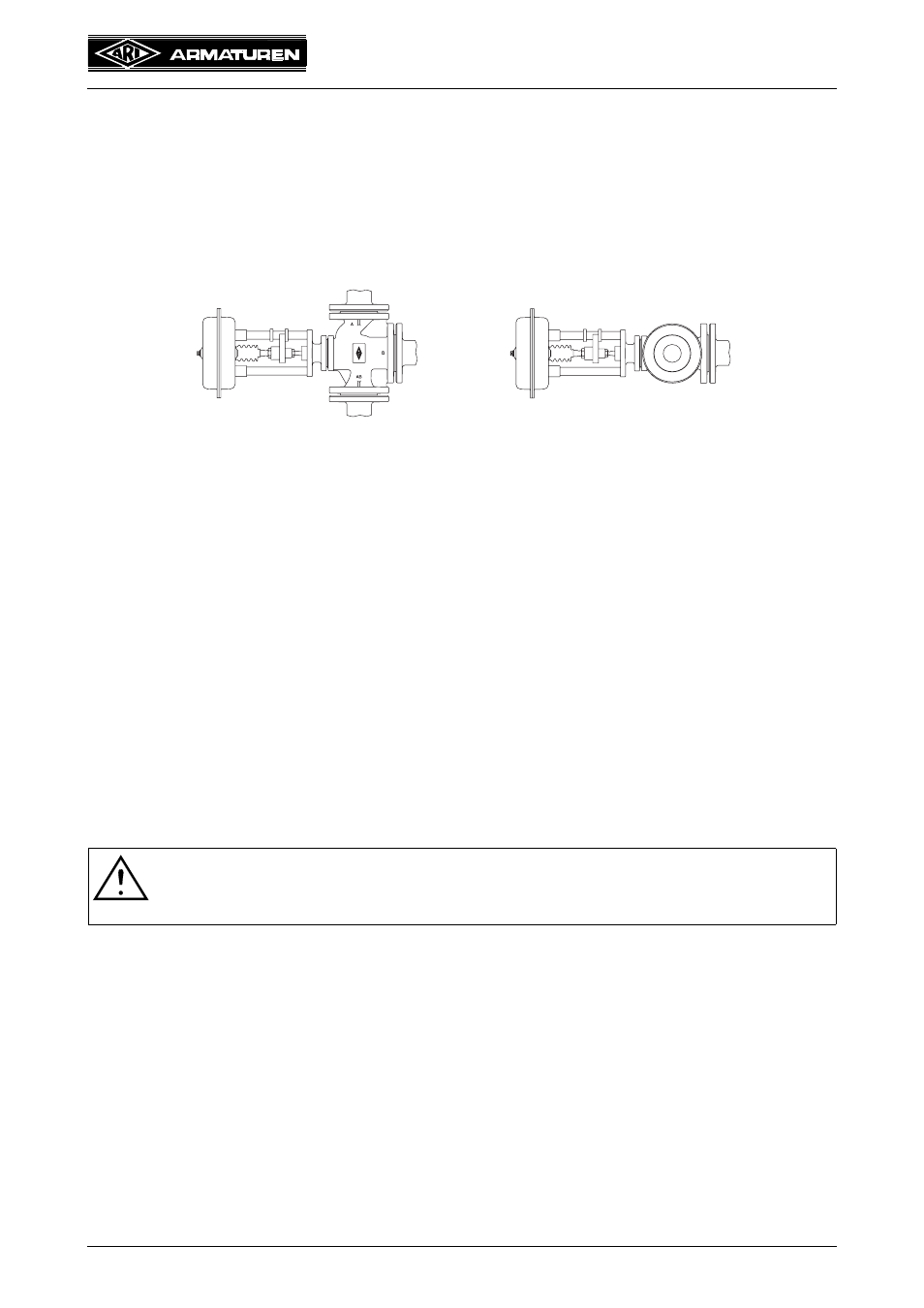

Fig. 10: Pipeline vertically

Fig. 11: Pipeline horizontally

ATTENTION !

Care must be taken with the bellow type valves when actuators are mounted or

removed. (Hold the valve-stem against turning with an open-end wrench!)

Series 450

Series 451

12 kN for DN 15- 50

18 kN for DN 15-100

29 kN for DN 65-100

37 kN for DN125-150 / 125v-150v

40 kN for DN125-150

59 kN for DN125v-150v