6 marking, 0 installation, 1 general notes on installation – ARI Armaturen FA800 EN User Manual

Page 7

Rev. 0040504003 2310

Page 7

Operating and installation instructions

Pneumatic actuators - FA160-800

4.6 Marking

5.0 Installation

5.1 General notes on installation

The following points should be taken into account besides the general principles governing

installation work:

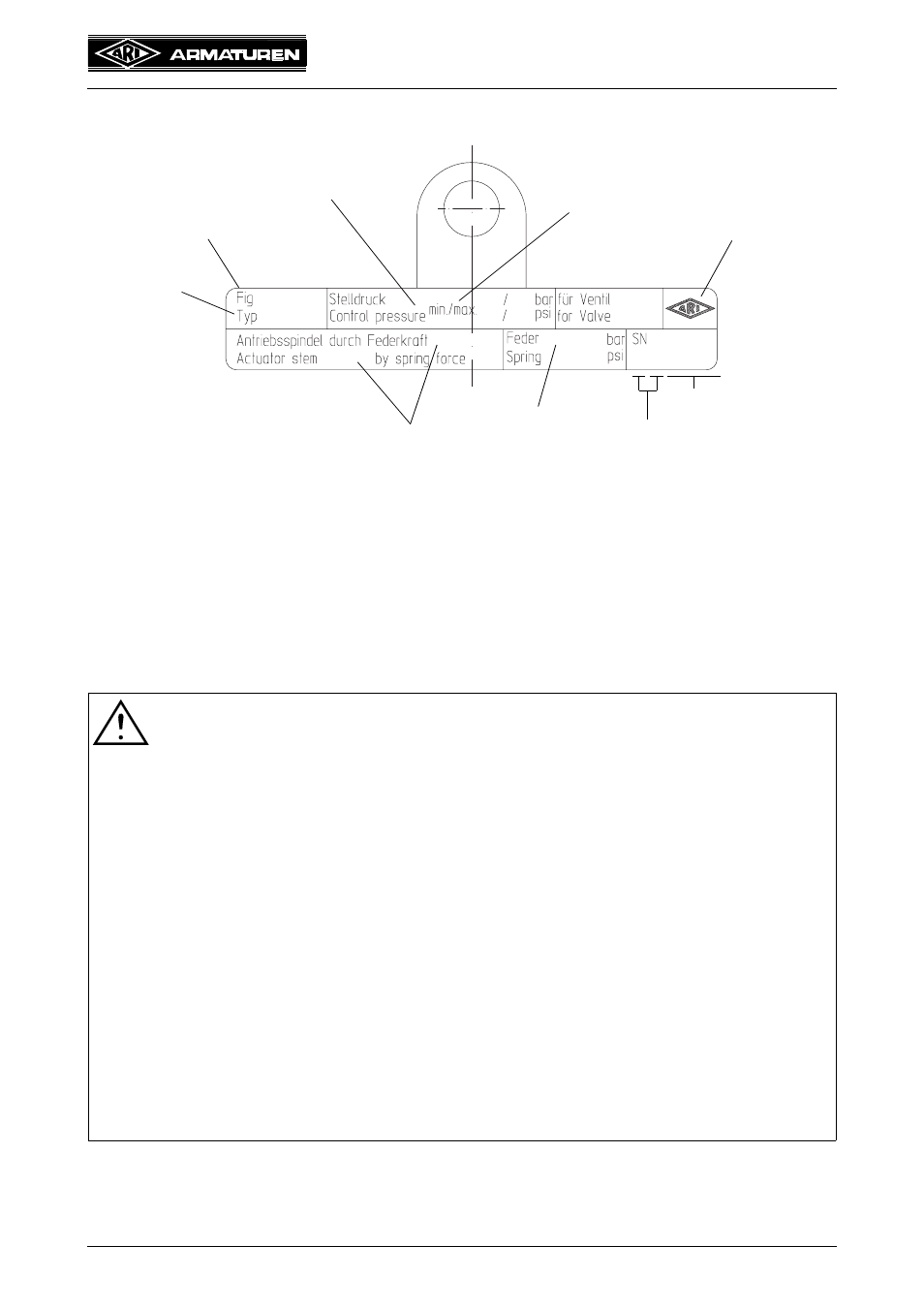

Fig. 4: Nameplate

- Address of manufacturer: refer to item 11.0 Warranty / Guarantee

ATTENTION !

- Observe the information provided in the operating manual of the applicable

valve.

- Observe the information provided in the operating manuals of all components

(for ex. position adjuster, filter reduction station, interlocking relay ...).

- Valve (all included) with traverse.

- Observe the applicable current driving power and the provided line length of the

chosen line cross section.

- The control air must be in accordance with the instructions given on the

nameplates of the actuator unit.

- The air quality should be in accordance with DIN IEC 60654-2.

- Personnel with knowledge of the rules and regulations is required for the

construction of the compressed air system.

- Only FABA-Supra valves with a two-piece stem can be retrofitted with an FA

actuator.

- Use an actuator that is suitable for the FABA-Supra valve installed (DN) as well

as for the prevailing operating conditions (refer to the rating plate).

- The plant should be shut down (i.e. in a pressureless state!) for safety reasons

prior to mounting the actuator to the FABA-Supra valve.

Manufacturer

Operating mode

Figure-Number

Type

min. necessary

operating pressure

Serial-No.

Year of manufacture clear speach

(1. and 2. position)

max. permissible

operating pressure

Spring range