Wiring connections, Input and power/output connections, Troubleshooting – Red Lion IRMA User Manual

Page 3

3

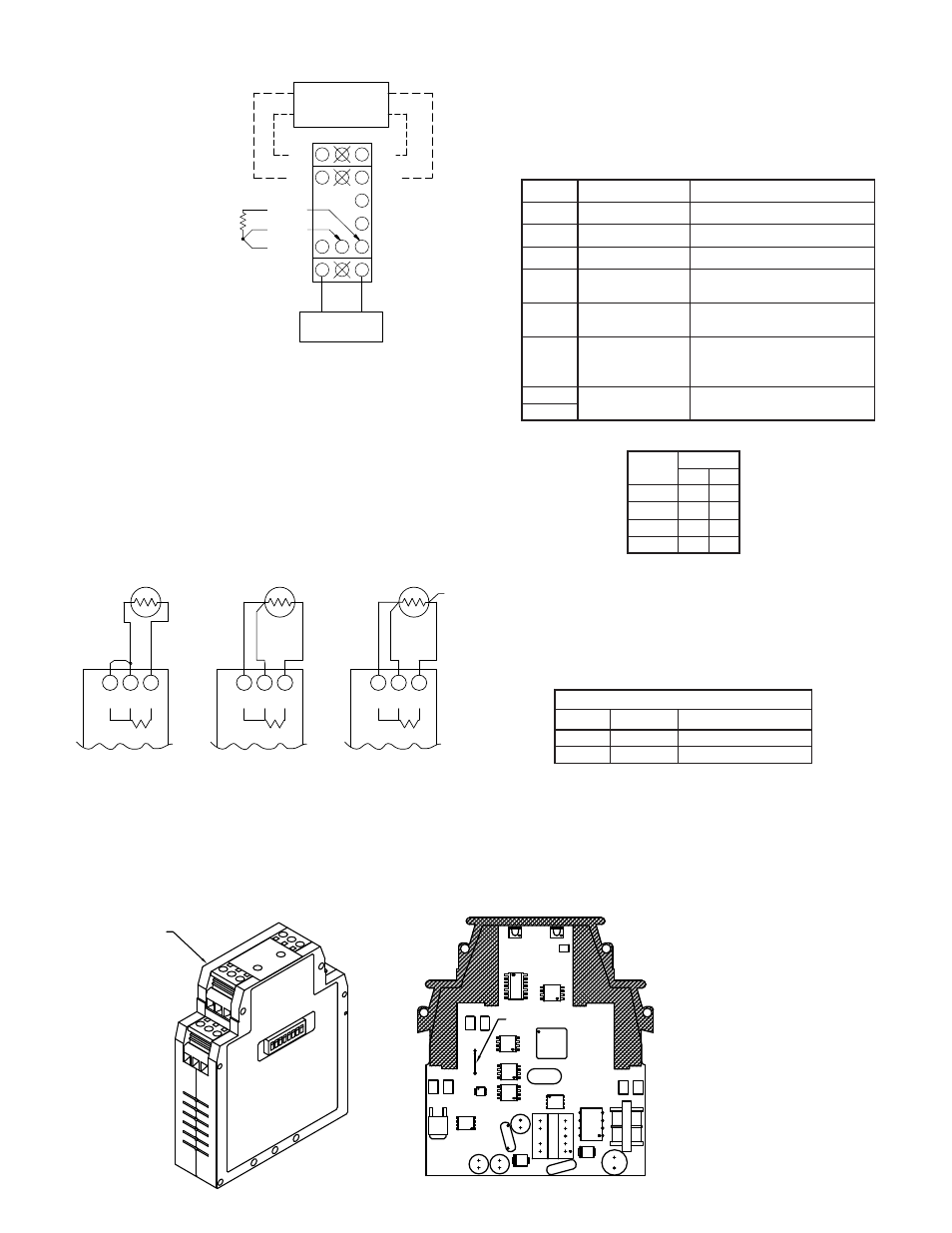

WIRING CONNECTIONS

All conductors should meet

voltage and current ratings for

each terminal. Also, cabling

should conform to appropriate

standards of good installation,

local codes and regulations. It

is recommended that power

supplied to the unit be

protected by a fuse or circuit

breaker. When wiring the unit,

use the numbers on the label

to identify the position

number with the proper

function. Strip the wire,

leaving approximately 1/4" (6

mm) of bare wire exposed

(stranded wire should be

tinned with solder). Insert the

wire into the terminal, and

tighten the screw until the

wire is clamped tightly.

INPUT AND POWER/OUTPUT CONNECTIONS

INPUT

When connecting the RTD or resistance device, be certain that the

connections are clean and tight. Attach the device to terminals #8 and #9. Install

a copper sense lead of the same gauge as those used to connect the device.

Attach one end of the wire at the probe where the lead connected to terminal #8

is attached and the other end to terminal #7. This configuration will provide

complete lead wire compensation. If a sense wire is not utilized, then Terminal

#7 should be shorted to terminal #8. To avoid errors due to lead wire resistance,

field calibration should be performed with a series resistance equal to the total

lead resistance in the system. Always refer to the probe manufacturer’s

recommendations for mounting, temperature range, shielding, etc.

OUTPUT

Connect the output signal wires to the desired output terminals. For voltage

output, use terminals #4 and #6; for current output, use terminals #1 and #3

observing proper polarity. Only one output may be used at a time. The unit is

factory set for a 4 to 20 mA output. The voltage output will track the current

output linearly within ±2.5% deviation of range endpoints.

To select 0 to 20 mA, output you must open the case and cut the wire jumper.

The jumper is located to the left side of the board as shown in the drawing.

POWER

Connect DC power to terminals #10 and #12 observing proper polarity. Be

certain DC power is within the 9 to 32 VDC specifications.

POWER LED

The IRMA has a green LED located on the front to indicate that power is

applied to the unit.

DIP SWITCH SETTING DESCRIPTIONS

Range switch settings (ON = 1 OFF = 0)

FACTORY SETTINGS

The unit is shipped from the factory calibrated for a 4 to 20 mA output using

a type 385 RTD in range 0. The IRMA should be Field calibrated by the

operator for the application environment it will be used in. If the unit is not

recalibrated by the operator, the following table lists the temperature ranges for

each RTD type.

TROUBLESHOOTING

For further technical assistance, contact technical support at the appropriate

company numbers listed.

Remove this

side of the

unit case.

WIRE JUMPER

ERROR

POWER

VDC+

10

RTD(S)

7

V+

4

I+

1

VDC-

RTD(+)

12

11

9

8

6

5

V-

3

2

I-

POWER SUPPLY

9 to 32 VDC

VOLTAGE METER

OR

CURRENT METER

MONITORING INSTRUMENT

RTD(-)

8

7

9

RTD

S

-

+

-

RTD

+

7

S

8

9

RTD

7

S

8

+

9

-

3-WIRE RTD

4-WIRE RTD

N.C.

2-WIRE RTD

SWITCH

LABEL

DESCRIPTION

1

OUTPUT CAL

Output Calibration

2

FIELD CAL

Field Calibration

3

BASIC CAL

Basic Calibration

4

385/392

RTD Type

5

OPEN SEN UP/DN

Open Sensor Detection -

Upscale (ON) / Downscale (OFF)

6

RTD/OHMS

Select Input Type -

Ohms (ON) / RTD (OFF)

7

8

RANGE

Sensor Range - 2 switch

combination setting

DIP SWITCH

RANGE

7

8

0

0

0

1

0

1

2

1

0

3

1

1

TYPE

385

RANGE

0

NOMINAL FACTORY FIELD CALIBRATION

TEMPERATURE RANGE

150°C to 606°C

392

0

150°C to 595°C