Function descriptions, Emc installation guidelines, Open sensor detection – Red Lion IRMA User Manual

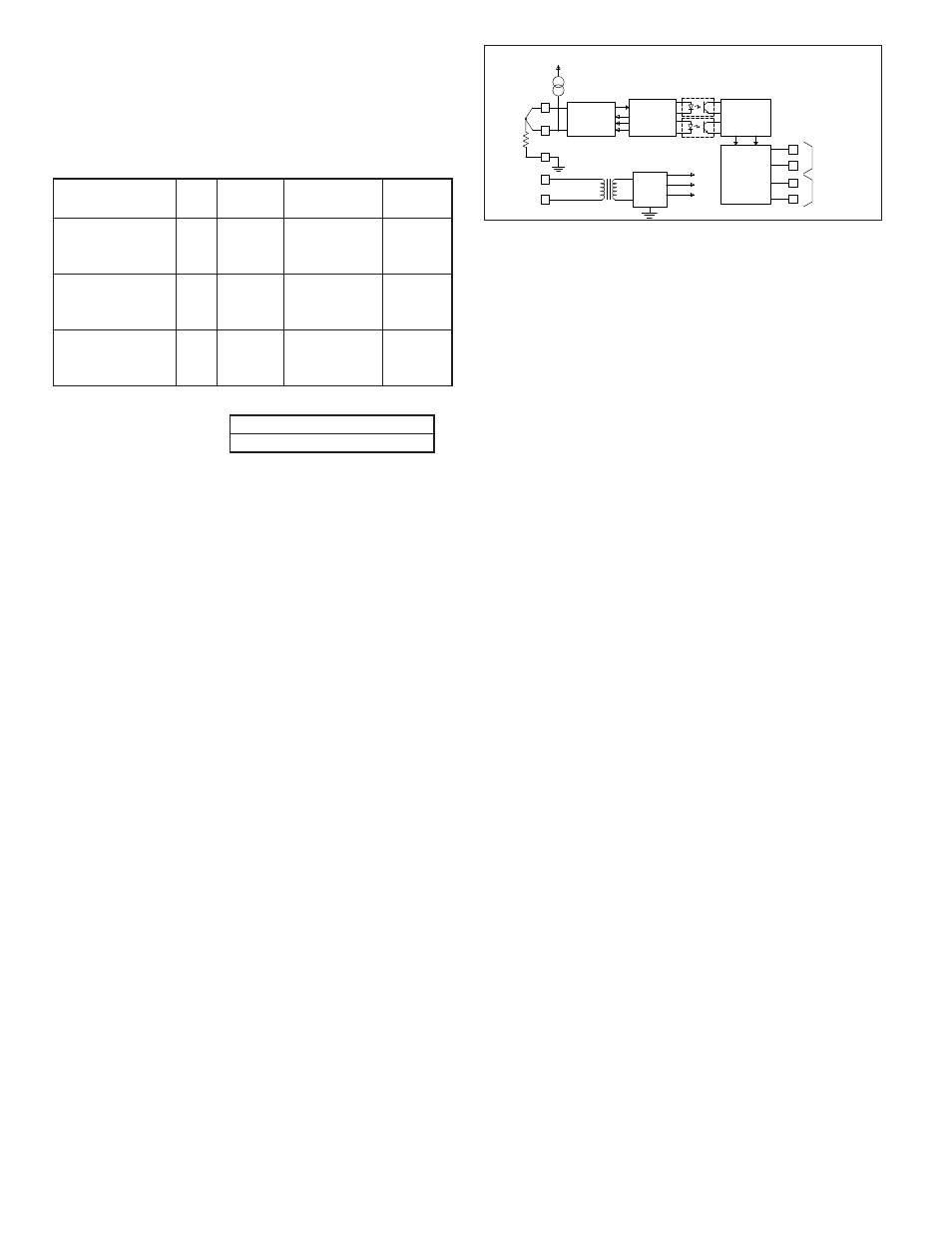

Page 2: Unit malfunction, Block diagram

2

8. RANGE & ACCURACY: (12 Bit resolution)

Accuracy:

( 0.075% Range + 0.1°C [Conformity]) at 23°C after 45 min.

warm-up, conforming to ITS-90.

Note: RTD Conformity does not apply to resistance input. For best accuracy,

calibration should be performed under operating conditions.

Relative Humidity: Less than 85% RH (non-condensing)

Span: The input span can be set to a min. of 1/8 of the full scale range,

anywhere within that range.

Range Accuracy

9. CERTIFICATIONS AND COMPLIANCES:

SAFETY

IEC 61010-1, EN 61010-1: Safety requirements for electrical equipment

for measurement, control, and laboratory use, Part 1.

ELECTROMAGNETIC COMPATIBILITY

Notes:

1. This device was designed for installation in an enclosure. To avoid

electrostatic discharge, precautions should be taken when the device is

mounted outside an enclosure. When working in an enclosure (ex. making

adjustments, setting switches etc.) typical anti-static precautions should be

observed before touching the unit.

2. Self-recoverable loss of performance during EMI disturbance at 10 V/m:

Analog output signal may deviate during EMI disturbance.

For operation without loss of performance:

Unit is mounted in a metal enclosure (Buckeye SM7013-0 or equivalent)

I/O and power cables are routed in metal conduit connected to earth ground.

Refer to the EMC Installation Guidelines section of this bulletin for additional

information.

10. ENVIRONMENTAL CONDITIONS:

Operating Temperature Range: -25°C to 75°C (-13°F to 167°F)

Storage Temperature Range: -40 to 85°C (-40°F to 185°F)

Operating and Storage Humidity: 85% max. relative humidity (non-

condensing) from -25°C to 75°C.

Vibration According to IEC 68-2-6: Operational 5 to 150 Hz, in X, Y, Z

direction for 1.5 hours, 2 g’s.

Shock According to IEC 68-2-27: Operational 30 g’s, 11 msec in 3 directions.

Altitude: Up to 2000 meters

11. MOUNTING: Universal mounting foot for attachment to standard DIN

style mounting rails, including top hat (T) profile rail according to EN50022

- 35

7.5 and 35

15, and G profile rail according to EN50035 - G32.

12. CONNECTION: Compression type terminal block

13. CONSTRUCTION: High impact black plastic case, Installation Category I,

Pollution Degree 2.

14. WEIGHT: 4.02 oz. (114.0 g)

FUNCTION DESCRIPTIONS

Open Sensor Detection

The output can be set to go Upscale or Downscale for the detection of an open

sensor. The nominal values for each output range are listed under RTD Break

Detection in the Specifications section. This setting is always active, so changes

to the setting are effective immediately.

Unit Malfunction

If the unit has scaling problems (output remains at -0.5 mA, 3.5 mA, or -0.5

VDC nominal), check the ERROR LED on the front of the unit. An E

2

PROM

problem is indicated when the ERROR LED is on. If the ERROR LED is on,

perform a Basic Calibration followed by a Field Calibration. Turn the power off

for 5 seconds. Turn power on and check if the ERROR LED is on. If the LED is

on, contact the factory.

EMC INSTALLATION GUIDELINES

Although this unit is designed with a high degree of immunity to

ElectroMagnetic Interference (EMI), proper installation and wiring methods

must be followed to ensure compatibility in each application. The type of the

electrical noise, source or coupling method into the unit may be different for

various installations. Cable length, routing and shield termination are very

important and can mean the difference between a successful or a troublesome

installation. Listed below are some EMC guidelines for successful installation in

an industrial environment.

1. Use shielded (screened) cables for all Signal and Control inputs. The shield

(screen) pigtail connection should be made as short as possible. The

connection point for the shield depends somewhat upon the application.

Listed below are the recommended methods of connecting the shield, in order

of their effectiveness.

a. Connect the shield only at the rail where the unit is mounted to earth ground

(protective earth).

b. Connect the shield to earth ground at both ends of the cable, usually when

the noise source frequency is above 1 MHz.

c. Connect the shield to common of the unit and leave the other end of the

shield unconnected and insulated from earth ground.

2. Never run Signal or Control cables in the same conduit or raceway with AC

power lines, conductors feeding motors, solenoids, SCR controls, and heaters,

etc. The cables should be run in metal conduit that is properly grounded. This

is especially useful in applications where cable runs are long and portable

two-way radios are used in close proximity or if the installation is near a

commercial radio transmitter.

3. Signal or Control cables within an enclosure should be routed as far away as

possible from contactors, control relays, transformers, and other noisy

components.

4. In extremely high EMI environments, the use of external EMI suppression

devices, such as ferrite suppression cores, is effective. Install them on Signal

and Control cables as close to the unit as possible. Loop the cable through the

core several times or use multiple cores on each cable for additional protection.

Install line filters on the power input cable to the unit to suppress power line

interference. Install them near the power entry point of the enclosure. The

following EMI suppression devices (or equivalent) are recommended:

Ferrite Suppression Cores for signal and control cables:

Fair-Rite # 0443167251 (RLC #FCOR0000)

TDK # ZCAT3035-1330A

Steward #28B2029-0A0

Line Filters for input power cables:

Schaffner # FN610-1/07 (RLC #LFIL0000)

Schaffner # FN670-1.8/07

Corcom #1VR3

Note: Reference manufacturer’s instructions when installing a line filter.

5. Long cable runs are more susceptible to EMI pickup than short cable runs.

Therefore, keep cable runs as short as possible.

ANALOG

OUTPUT

CIRCUITRY

1

3

CIRCUITRY

CONTROL

PWM

POWER

SUPPLY

22V

3V

CIRCUITRY

PROCESS

CONVERTER

A/D

CURRENT

OUTPUT

12

10

4V

POWER

DC

6

4

+

+

-

-

VOLTAGE

OUTPUT

3V

RTD

9

8

7

0.170mA

BLOCK DIAGRAM

Enclosure class B

Level 4; 30 A/m

Level 4; 2 kV I/O

Level 3; 2 kV power

150 KHz

80 MHz

Level 3; 10 V/rms

EN 55011

EN 61000-4-8

EN 61000-4-4

EN 61000-4-6

RF interference

Emission to EN 50081-2

Power frequency magnetic fields

Fast transients (burst)

RF conducted interference

80 MHz - 1 GHz

Level 3; 10 V/m

2

EN 61000-4-3

Electromagnetic RF fields

EN 61000-4-2

Immunity to EN 50082-2

Electrostatic discharge

Level 3; 8 kV air

Level 2; 4 kV contact

1

INPUT

RANGE

DIP SWITCH

TYPE RANGE

4 6 7 8

TEMPERATURE

& OHMS RANGE

RANGE

ACCURACY

0

0 0 0 0

-160 to 654°C

0.61°C

1

0 0 0 1

-108 to 207°C

0.24°C

2

0 0 1 0

-5 to 414°C

0.31°C

RTD alpha = 0.00385

3

0 0 1 1

194 to 608°C

0.31°C

0

1 0 0 0

-157 to 640°C

0.60°C

1

1 0 0 1

-106 to 203°C

0.23°C

2

1 0 1 0

-5 to 406°C

0.31°C

RTD alpha = 0.00392

3

1 0 1 1

190 to 596°C

0.30°C

0

0 1 0 0

35.5 to 331.0

0.222

1

0 1 0 1

57.0 to 178.5

0.091

2

0 1 1 0

98.0 to 252.0

0.116

OHMS

3

0 1 1 1

173.5 to 316.5

0.107

Total Error

( ±0.61°C +

±0.1°C)

=

±0.71°C

Accuracy Example:

RTD 385 Range “0”

-160°C to 654°C

Note: DIP switch settings

ON = 1

OFF = 0

Conformity

Range