Wiring connections, Installation, Application – Red Lion IAMA0006 User Manual

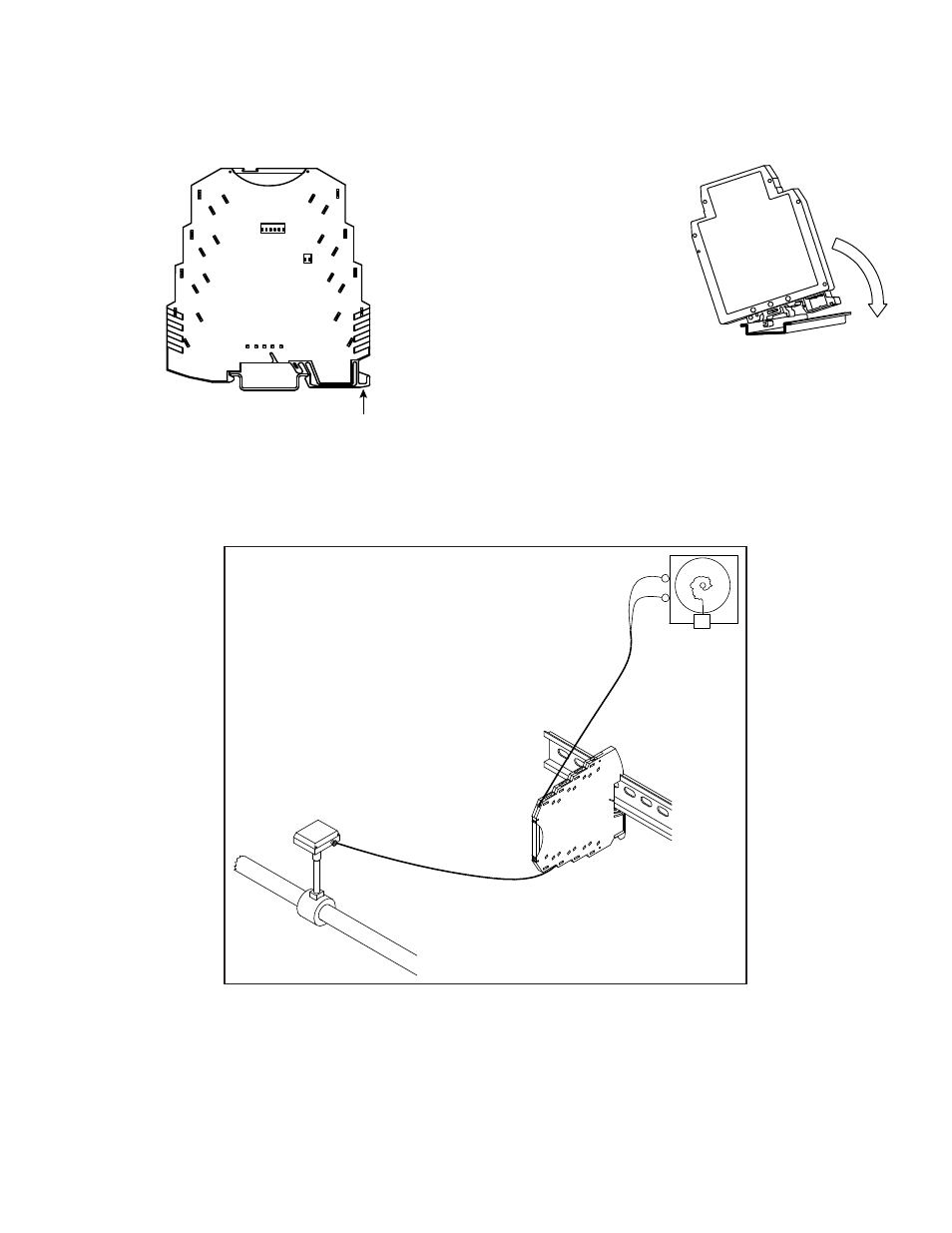

Page 3: T rail installation, Din rail release latch

3

WIRING CONNECTIONS

Primary power is connected to terminals 7 or 3 (19.2 – 30 VDC) and 8 or 4

(GND 3). For best results, the power should be relatively “clean” and within the

specified variation limits. Drawing power from heavily loaded circuits or from

circuits that also power loads that cycle on and off, should be avoided.

The input signal is connected to pins 1 (In U,I) and 2 (GND 1). Connections

for the output signal are made on pins 5 (Out U,I) and 6 (GND 2).

INSTALLATION

The unit is equipped with a universal mounting foot for attachment to

standard DIN style top hat (T) profile rail according to EN50022 - 35 x 7.5 and

35 x 15. The unit should be installed in a location that does not exceed the

maximum operating temperature and provides good air circulation. Placing the

unit near devices that generate excessive heat should be avoided.

T Rail Installation

To install the IAMA on a “T”

style rail, angle the module so that

the top groove of the “foot” is

located over the lip of the top rail.

Push the module toward the rail

until it snaps into place. To

remove a module from the rail,

insert a screwdriver into the slot

on the bottom of the “foot”, and

pry upwards on the module until it

releases from the rail.

APPLICATION

Cost efficiency measurements of a printing company included the reduction

of bulk stock of the various inks used in their printing processes. The

company currently had various ink flow and level devices with different

current and voltage outputs and wanted to record these measurements into a

control room PC. Several IAMA Universal Signal Conditioning Modules

were the answer. The IAMA’s universal input allowed for easy signal

conditioning of the various output signals to the required PC’s Bus Board

0 to 10 VDC input signal. In this case, the IAMA’s re-transmitted 0 to 10

VDC output was field calibrated, negating the expense and time

required to rewrite the PC’s software parameters. In addition to

accepting multiple signal types, the IAMA also provides the

necessary electrical isolation between the control room PC

and the hazards of the printing floor electrical noise.

5

6

7

8

-

+

RECORDER

CHART

FLOW

SENSOR

0-5 VDC

IAMA6

1

6

1 2

off

S1

on

S2

on

off

3 19.2...30VDC

1 IN UI

2 GND1

OUT UI 5

GND2 6

4 GND3

19.2...30VDC 7

GND3 8

DIN rail release latch