State SBS100 76NE User Manual

Page 15

15

If the water heater is being installed as a replacement for an existing

heater in pre-existing venting, a thorough inspection of existing venting

system must be performed prior to any installation work.

VENT DAMPERS - Any vent damper, whether it is operated thermally

or otherwise must be removed if its use inhibits proper drafting of the

water heater.

Thermally Operated Vent Dampers: this gas-fired water heater has

a thermal efficiency at or above 80% which may produce a relatively

low flue gas temperature. Such temperatures may not be high enough

to properly open thermally operated vent dampers. This would cause

spillage of the flue gases and may cause carbon monoxide poisoning.

Vent dampers must bear evidence of certification as complying with

the current edition of the American National Standard ANSI Z21.66

CGA 6.14 (covering electrically and mechanically actuated vent

dampers). Before installation of any vent damper, consult the local

gas utility for further information.

To insure proper venting of this gas-fired water heater, the correct

vent pipe diameter must be utilized. Any additions or deletions of

other gas appliances on a common vent with this water heater may

adversely affect the operation of the water heater. Consult your gas

supplier if any such changes are planned.

For proper venting in certain installations, a larger diameter vent

pipe may be necessary. Consult your gas supplier to aid you in

determining the proper venting for your water heater from the vent

tables in the current edition of the National Fuel Gas Code ANSI

Z223.1/NFPA 54 or the Natural Gas and Propane Installation Code

cAN\cSA B 149.1.

Periodically check the venting system for signs of obstruction or

deterioration and replace if needed.

The combustion and ventilation air flow must not be obstructed.

The water heater with draft hood installed must be connected to a

chimney or listed vent pipe system, which terminates to the outdoors.

Never operate the water heater unless it is vented to the outdoors

and has adequate air supply to avoid risks of improper operation,

explosion or asphyxiation.

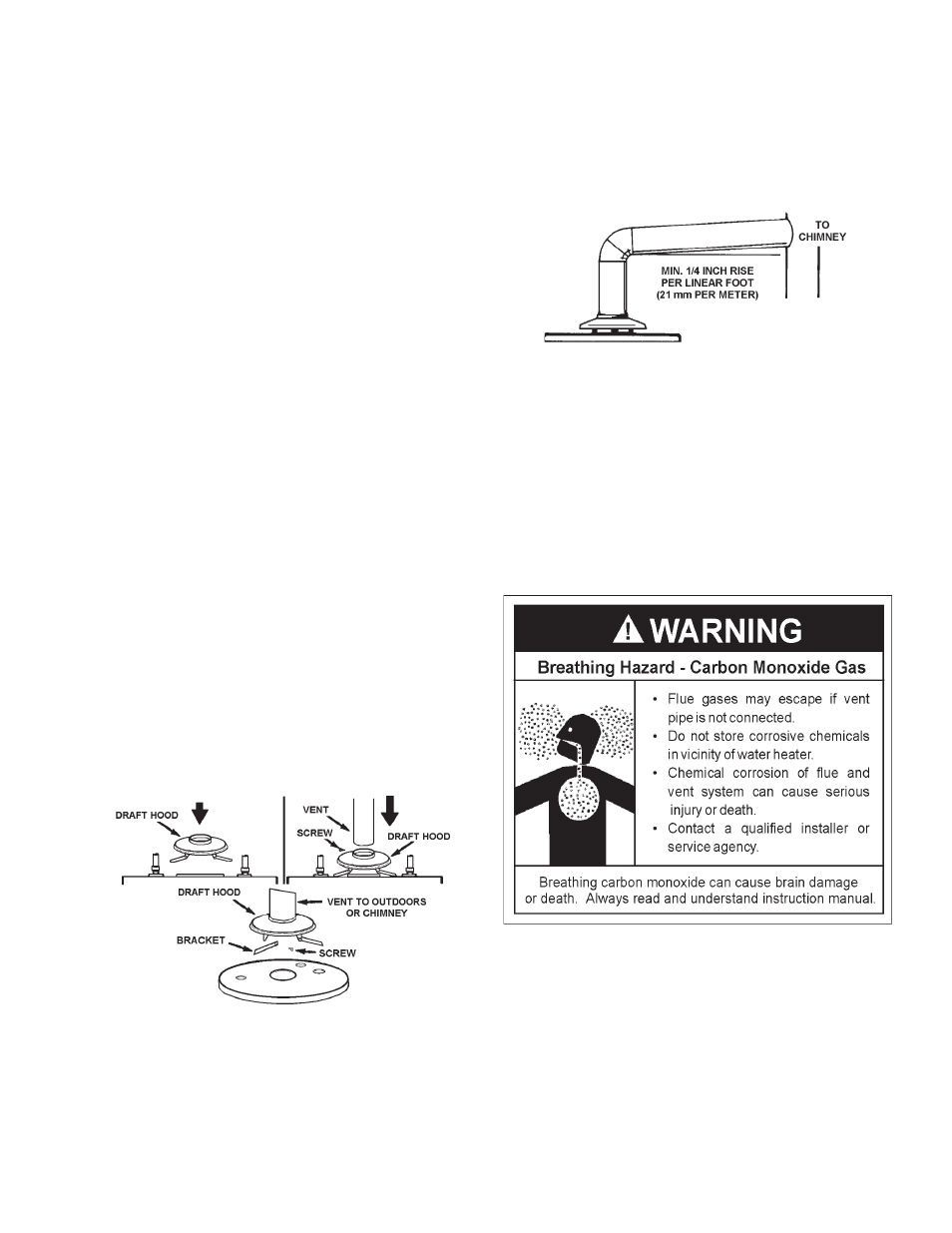

• For proper draft hood attachment, the draft hood legs may be

angled slightly inward.

• Place the draft hood legs in the receiving holes on the top of the

water heater. The legs will snap in the holes to give a tight fit.

Secure draft hood with the supplied brackets.

• Place the vent pipe over the draft hood. With the vent pipe in position,

drill a small hole through both the vent pipe and draft hood. Secure

them together with a sheet metal screw. See Figure 13.

Obstructed or deteriorated vent systems may present serious health

risk or asphyxiation.

fIGure 13.

The vent pipe from the water heater must be no less than the

diameter of the draft hood outlet on the water heater and must

slope upward at least 1/4 inch per linear foot (21 mm per meter).

See Figure 14.

All vent gases must be completely vented to the outdoors of the

structure (dwelling). Install only the draft hood provided with the

new water heater and no other draft hood.

Vent pipes must be secured at each joint with sheet metal screws.

fIGure 14.

There must be a minimum of 6” (153 mm) clearance between single

wall vent pipe and any combustible material. Fill and seal any

clearance between single wall vent pipe and combustible material

with mortar mix, cement, or other noncombustible substance. For

other than single wall, follow vent pipe manufacturer’s clearance

specifications. To insure a tight fit of the vent pipe in a brick chimney,

seal around the vent pipe with mortar mix cement.

Failure to have required clearances between vent piping and

combustible material will result in a fire hazard.

Be sure vent pipe is properly connected to prevent escape of

dangerous flue gases which could cause deadly asphyxiation.

Chemical vapor corrosion of the flue and vent system may occur

if air for combustion contains certain chemical vapors. Spray can

propellants, cleaning solvents, refrigerator and air conditioner

refrigerants, swimming pool chemicals, calcium and sodium

chloride, waxes, bleach and process chemicals are typical

compounds which are potentially corrosive.