System component part storage tank installation – State Standard Systems User Manual

Page 7

7

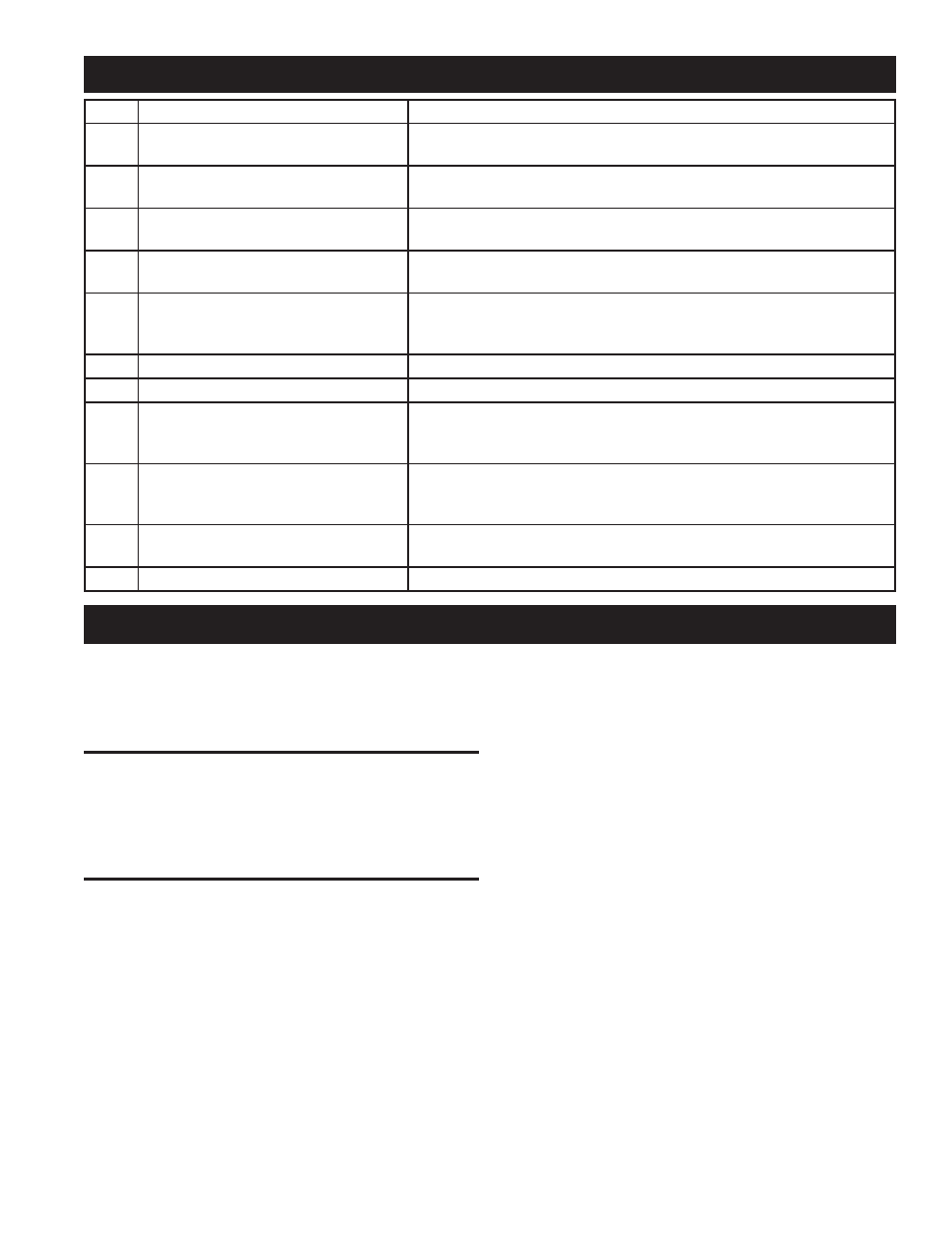

item

component

function

1

Solar collector

Absorbs the sun’s heat energy and transfers this to the heat transfer

fluid circulating through the collector.

2

Solar storage tank

Stores potable water heated by solar generated heat or installed

back-up electric resistance element.

3

Heat exchanger (Not Shown)

Transfers the heat from the collector loop to the potable water in the

solar storage tank.

4

Solar Loop Expansion tank

Allows for the expansion and contraction of the heat transfer fluid as

it heat and cools.

5

Temperature and Pressure relief

valve

Required by plumbing code to automatically open and dump water if

the storage tank exceeds 150 PSI of pressure or 210° F in tempera-

ture.

6

Air vent

Purges air from the collector loop fluid during the installation.

7

Drain valve

Used to drain the heat transfer fluid from the collector loop.

8

Mixing valve

Used to temper hot water from the solar storage tank with cold inlet

water to maintain appropriate temperature hot water delivered from

the system.

9

Solar pump station

Controls the flow of heat transfer fluid from the collectors to the tank/

heat exchanger. For a detailed description of the solar pump station

see page 20.

10

Temperature sensor

Tank and collector sensor work together to turn the circulating

pump(s) on and off at preset temperature differentials.

11

Cold Water Cut-Off Valve

Isolates the tank from incoming water supply.

sYstem component part

storaGe tanK installation

Never operate the electrical heating element without being

certain the solar water heater is completely filled with water.

If any air is left in the top of the tank, the heating element

will burn out.

local codes

The installation of this solar water heater must be in

accordance with these instructions and all applicable local

codes and electric utility requirements. In the absence of

local codes, install in accordance with the latest edition of the

National Electrical Code (NFPA-70).

temperature-pressure relief valve

For protection against excessive pressures and temperatures

in this water heater, install temperature-pressure protective

equipment required by local codes, but not less than a

combination temperature-pressure relief valve certified by

a nationally recognized testing laboratory that maintains

periodic inspection of production of listed equipment or

materials, as meeting the requirements for Relief Valves for

Hot Water Supply Systems, the latest edition of ANSI Z21.22.

This valve must be marked with a maximum set pressure not

to exceed the marked hydrostatic working pressure of the

water heater (150 lbs./sq. in.).

Install the temperature-pressure relief valve directly into the

fitting of the water heater. Position the valve downward and

provide a discharge pipe that must terminate a maximum

of six inches above a floor drain or external to the building.

In cold climates, it is recommended that the discharge pipe

be terminated at an adequate drain inside the building. Be

certain that no contact is made with any live electrical part.

The discharge opening must not be blocked or reduced in size

under any circumstances. Excessive length, over 15 feet, or

use of more than two elbows can cause restriction and reduce

the discharge capacity of the valve.

No valve or other obstruction is to be placed between the

temperature-pressure relief valve and the tank. Do not

connect tubing directly to discharge drain unless a 6” air

gap is provided. To prevent bodily injury, hazard to life

or damage to property, the temperature-pressure relief

valve must be allowed to discharge water in quantities

should circumstances demand. If the discharge pipe is not

connected to a drain or other suitable means, the water flow

may cause property damage.

The Discharge Pipe:

• Shall not be smaller in size than the outlet pipe size of the

temperature-pressure relief valve, or have any reducing

couplings or other restrictions.

• Shall not be plugged or blocked.

• Shall be of material listed for hot water distribution.

• Shall be installed so as to allow complete drainage of both the

temperature-pressure relief valve, and the discharge pipe.

• Must terminate a maximum of six inches above a floor drain

or external to the building. In cold climates, it is recommended

that the discharge pipe be terminated at an adequate drain

inside the building.