Pump station installation – State Standard Systems User Manual

Page 22

22

safetY equipment

For protection against excessive pressures in the collector

loop a pressure relief valve is integrated into the solar

pump station. Drain tubing must be installed in the valve

outlet so that any discharge will exit only within 6 inches

above, or at any distance below the structural floor. Be

certain that no contact is made with any live electrical part.

The discharge opening must not be blocked or reduced in

size under any circumstances. Excessive length, over 15

feet, or use of more than two elbows can cause restriction

and reduce the discharge capacity of the valve.

Do not connect tubing directly to discharge drain unless a

6” air gap is provided. To prevent bodily injury, hazard to

life, or damage to property, the relief valve must be allowed

to discharge fluid in quantities should circumstances

demand. If the discharge pipe is not connected to a drain

or other suitable means, the fluid may cause property

damage.

Wall mountinG the solar pump station

attention: TO PREVENT DAMAGE TO PROPERTY,

THE LOCATION OF INSTALLATION MUST BE DRY,

LOAD-CARRYING AND FROST-PROOF TO PREVENT

MATERIAL DAMAGE TO THE INSTALLATION.

1. Choose the position to install the solar pump station

next to the storage tank (noting that the tank solar loop

inlet (from collector) and outlet (to pump) are on the

right side of the tank)

2. Remove the temperature gauges (C,E) by grasping the

frame and pulling straight forward.

3. Remove the front cover (D) of the solar station.

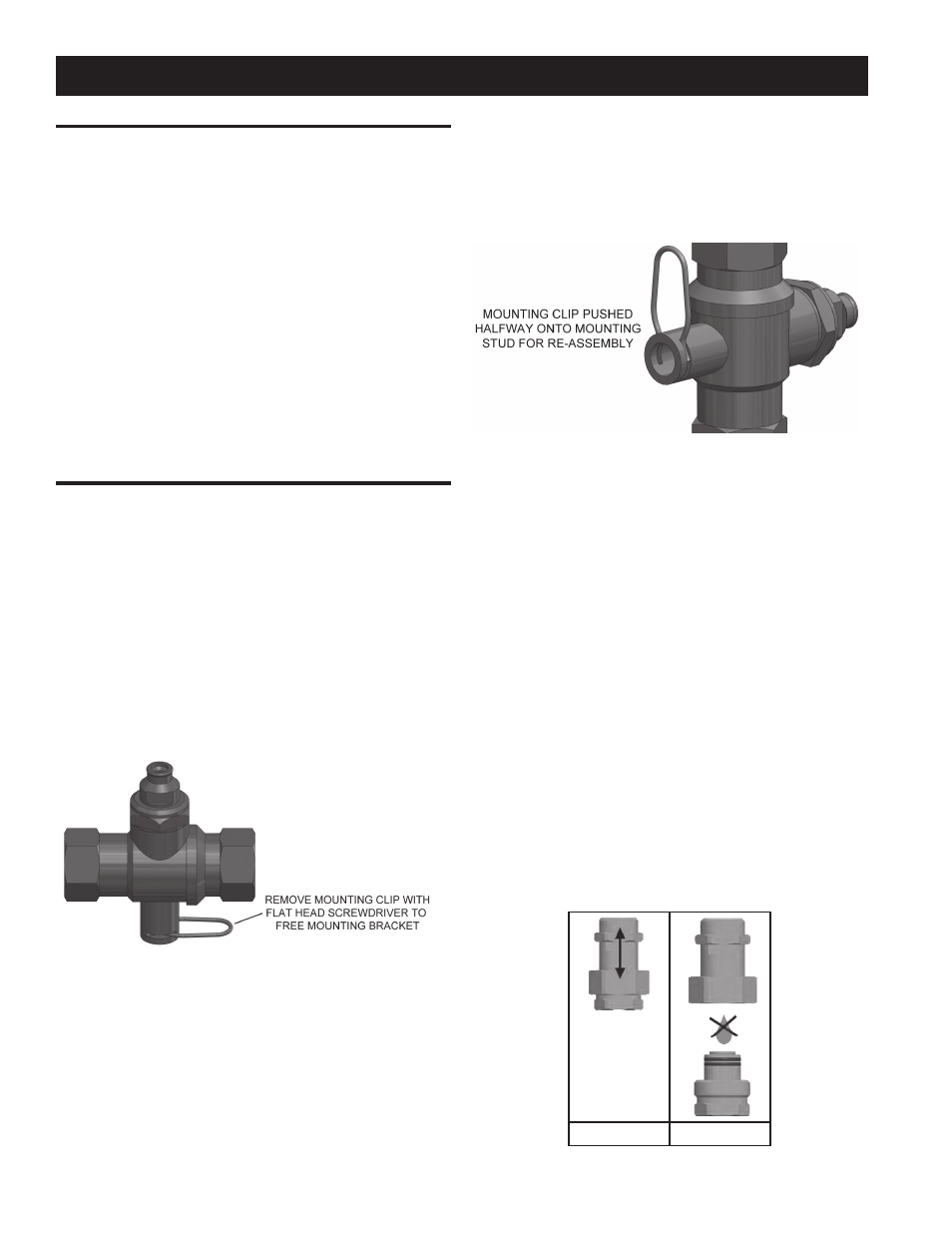

4. Remove the retainer clips behind the isolation ball

valves (J, Q) with a flat head screw driver to free the

mounting plate from the station (see Figure 22).

Figure 22.

Note: To aid in later assembly, while each leg of the station

assembly is removed from the bracket, an extension leg of

¾” copper tubing can be attached to the bottom threaded

connector using the ¾” female NPT sweat adaptor provided.

5. Line the mounting plate up level on the wall and mark

the drill holes. (Holes will be 5 ¾” (146 mm) apart). Drill

the two holes with a 3/8” drill bit and mount the plate

with either the masonry mounting hardware or drywall

hardware provided.

6. After the mounting plate is secured to the wall replace

the solar pump station back cover, insert the retaining

clips half way onto the mounting retaining stud (see

Figure 23) behind the isolation ball valves (J, Q), push

the assembly onto the bracket mounting stud and push

the clip down into place. Ensure assembly is properly

locked into place.

Figure 23.

7. Connect the stainless steel corrugated hose to the

safety group (N). Do not forget to insert the seal.

8. Choose the position for the expansion tank bracket

on the wall beside the solar pump station. Fasten the

bracket to the wall with the enclosed hardware (masonry

or drywall).

9. Unscrew the tank connector to separate the two halves.

The top half should be pushed onto the mounting

bracket and the lock ring tightened. The bottom half

should be attached to the ¾” threads on the expansion

tank. Do not forget to insert the seal.

10. Make sure that you are able to reach the drain valve

and all access panels when the solar station is in place.

This will make it easy to service the solar station.

NOTE: The tank connector allows you to isolate the

expansion tank from the solar circuit (Figure 24). When

the nut is unscrewed the valves in each half of the tank

connector are automatically closed tightly by the integrated

springs. Each side remains closed until the two halves are

screwed back together and the valves are forced open.

The expansion tank should not be connected to the system

until it has been flushed and charged.

FLOW

CLOSED

Figure 24.

pump station installation