State Standard Systems User Manual

Page 23

23

11. Check and set the pressure of the air bladder in the

expansion tank to 25 psi. If the pressure is higher bleed

pressure out until it is correct. If the pressure is too low

add air by use of a compressor or bicycle pump until

the pressure is correct.

12. Plumb the solar pump station to the storage tank

and to the collector: The tank connections should

use ¾” copper pipe and can be connected using

the threaded adaptors provided. The collector

connections should use ½” copper pipe and can be

connected with the compression fittings provided.

The total piping run in the solar loop should not exceed

200 equivalent feet. Failure to limit the line length may

cause poor system performance and lead to premature

pump failure.

13. Add the supplied copper drain valve to the lowest point

in the collector loop (near the tank by the bottom coil

outlet labeled “to pump” in most cases)

14. Install a discharge pipe to the pump station relief valve

that must terminate a maximum of six inches above a

floor drain or external to the building.

installing the ½” copper to and from the collector using

the compression fittings.

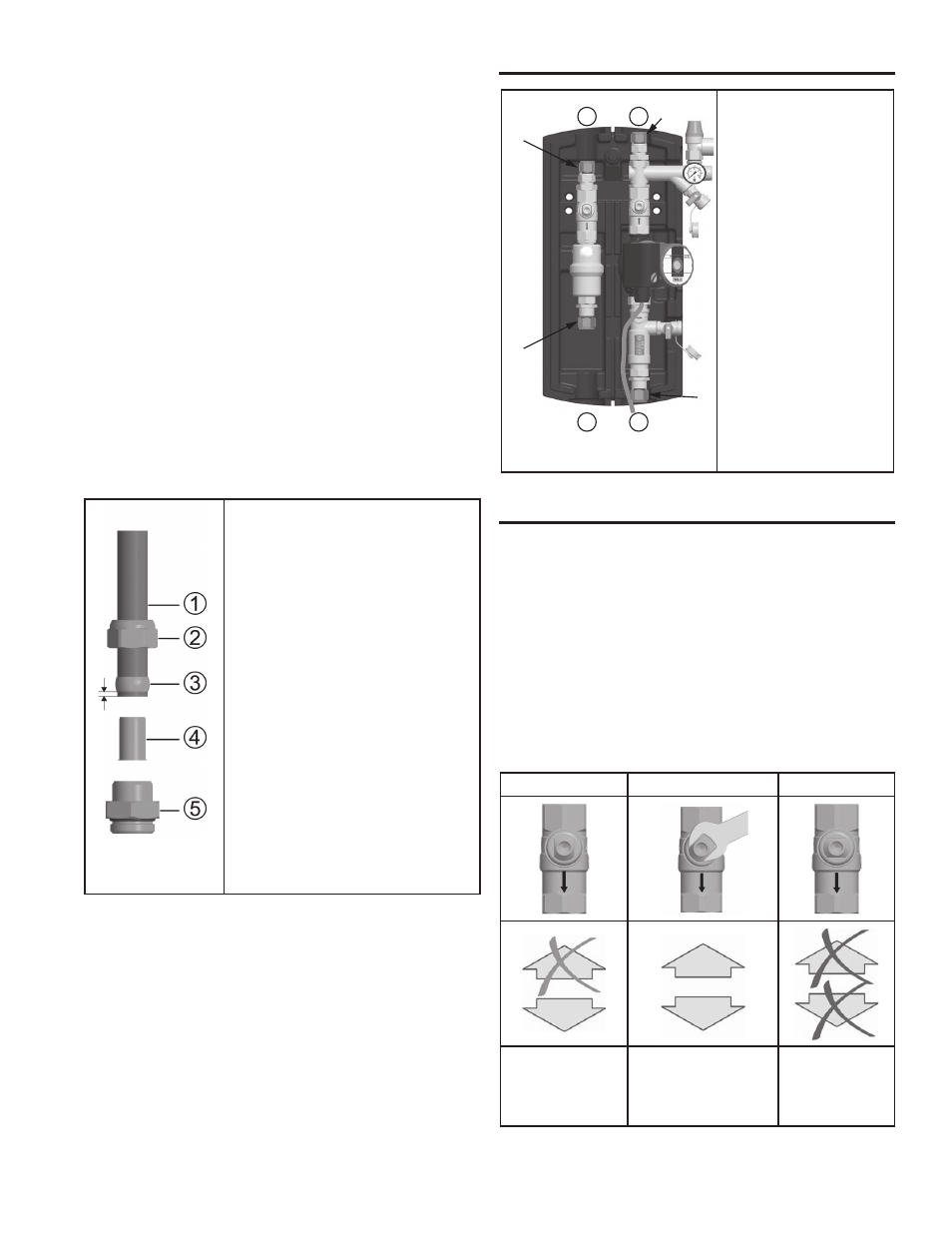

1. Push the union nut

and

the cutting ring

onto the

copper pipe

. The pipe

must protrude at least 3/8”

(3 mm) from the cutting ring

in order to ensure the force

transmission and the sealing.

2. Insert the support sleeve

into

the copper pipe.

3. Insert the copper pipe with the

plugged-on individual parts (

,

and

) all the way into the

housing of the compression

fitting

.

4. First screw the union nut

manually.

5. Tighten the union nut

by

rotating one full turn. Hold the

housing of the compression

fitting

to avoid rotation in order

to avoid damaging the sealing

ring.

Figure 25.

plumBinG confiGuration

V

L

H

K

1

2

3

4

1. ½” copper tube - from

the collector outlet

(top) to the collector

return compression

fitting (K)

2. ½” copper tube – from

the collector inlet

(bottom) to the collector

supply compression

fitting (L)

3. ¾” copper tube – from

the upper tank coil

inlet marked “from

collector” to the tank

supply threaded fitting

(H)

4. ¾” copper tube –

from the lower tank

coil outlet marked

“to pump” to the tank

return threaded fitting

(V)

Figure 26.

function

check valves

The solar station is equipped with check valves in the supply

and the return ball valve (J, Q).

For filling, venting and flushing of the installation the check

valves must be turned to the correct position. To set the

proper position for the check valves take off the temperature

gauges (C, E), remove the top cover (D) and turn the ball

valves into the proper position using a wrench. See Figure

27. In the 45° position the balls in the ball valves push the

check valves open.

During operation the ball valves must be in 0° position.

0°

45°

90°

Check valve is

operating, flow

only in flow

direction

Check valve is not

operating, flow in

both directions.

Ball valve

closed,

no flow.

Figure 27.