A.R.I. D-070 EN User Manual

Page 3

A.R.I. FLOW CONTROL ACCESSORIES Ltd.

www.arivalves.com [email protected] Tel: 972-4-6761899

MAINTENANCE INSTRUCTIONS D-070

EnM-D070-10

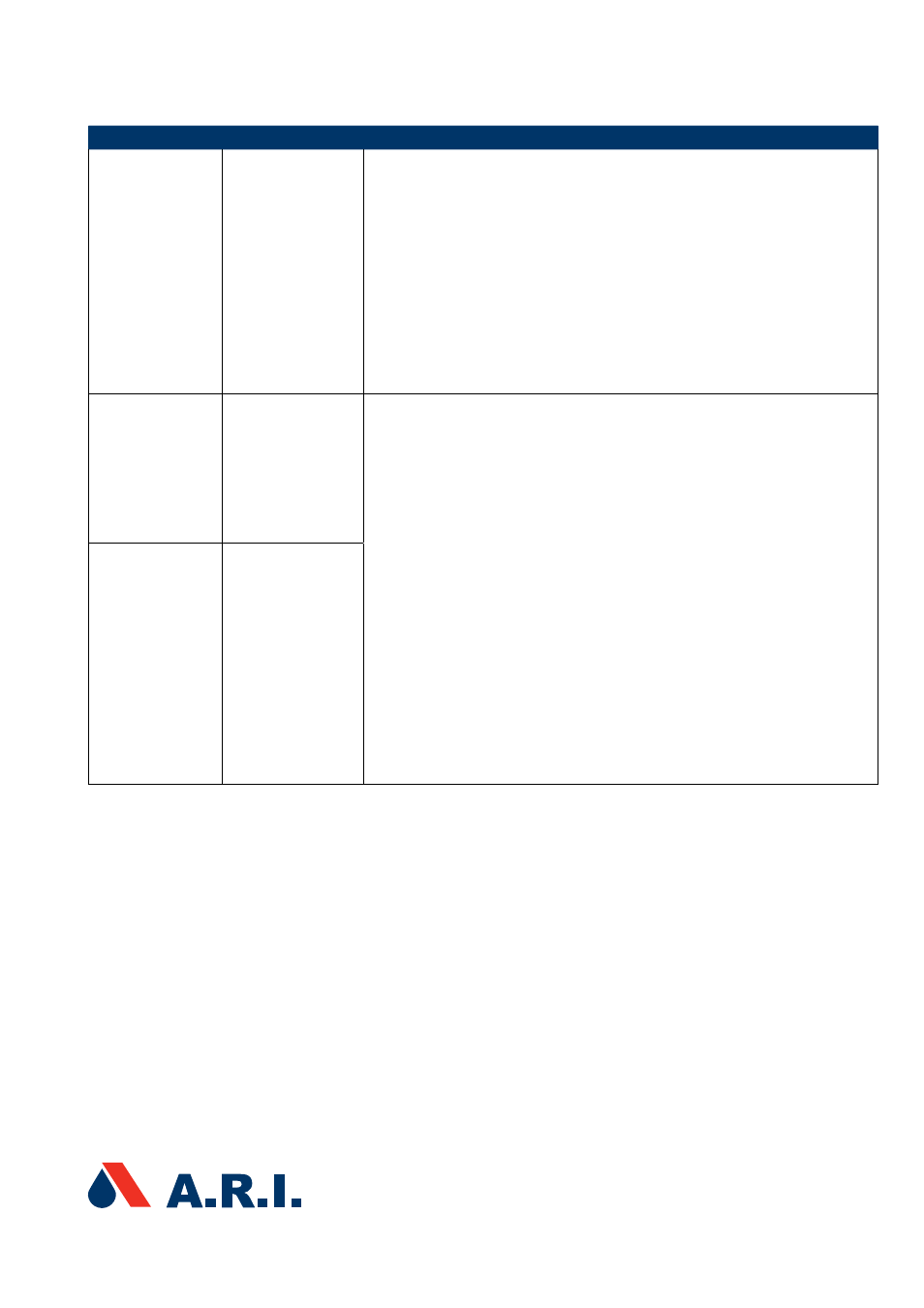

PROBLEM

REASON

SOLUTION

1. Leaking from

the DRAIN

PORT #1(2).

Debris or scale

build-up on the

Rolling Seal (2).

1. Shut off the isolating valve on the riser below the air valve . Unscrew the

Operating Valve Body (1).

2. Remove the Clamping Stem (3) and the Operating Assembly (4). Wash the

inside of the body, the Clamping Stem, the Operating Assembly, the Rolling

Seal (2), and the O-ring (6) with clean water.

3. Gently wash and clean the sealing area inside the valve body.

4. Check the O-ring (6) visually for any defects. Replace if needed .

5. Check and make sure that the Rolling Seal (2) is intact (not torn or cracked)

and is positioned precisely in the middle of its groove in the Operating

Assembly. Replace if needed. The disc at the bottom of the Operating

Assembly (Fig 4) should be loose and move freely.

Do not tighten the holding screw.

2.1. Leaking

from the DRAIN

PORT #2 (2).

Debris or

unwanted object

caught in the

Diaphragm

Assembly (9).

1. Shut off the isolating valve on the riser below the air valve .

2. Unscrew the bolts (8) (with the aid of 2 hex keys, size 19 mm) that connect

the main valve cover (7) to its body (10).

3. Remove the Air & Vacuum Sealing Assembly (9) from the body .

4. Wash the Body (10) and the Cover (7) in clean water in order to remove

coarse grime or accumulated scale.

5. Wash the Air & Vacuum Sealing Assembly (9) and check the rubber parts

for any tears .

6. Make sure that the Drill Hole (D-070 sizes 3", 4") is clean and the passage

(D-070 all sizes) is open.

7. Make sure the lower sealing assembly is intact and not torn.

8. Replace the whole Air & Vacuum Sealing Assembly (9) if any of the above

parts are torn or damaged .

9. Do not open screws of the assembly under any circumstances.

10. Make sure that there is no dirt or debris around the sealing area of the

dynamic valve body.

11. Replace the assembly in the body, reassemble in reverse order, then fasten

and tighten all bolts .

12. Open the isolating valve beneath the air valve, making sure that there are no

leaks.

2.2. Leaking

from the DRAIN

PORT #2 (2).

Torn Sealing

Assembly (Fig 5)

or Diaphragm (9).

TROUBLESHOOTING GUIDE