E 21, Table 4 co, Installation – Outback Power Systems GS4048A Installation Manual User Manual

Page 23

Installation

21

Table 4 DC Conductor Size and Torque Requirements

Inverter

Nominal DC Amps

(Minimum, per breaker)

(Derated 125%)

Conductor Size

(Minimum, per breaker)

Breaker Size

GS8048A

104

2/0 AWG 0.105 in²) or 70 mm²

175 Adc/AIC 10kA

GS4048A

104

2/0 AWG 0.105 in²) or 70 mm²

175 Adc/AIC 10kA

Terminal Location

Torque Requirements

Inverter DC Terminals

60 in-lb (6.9 Nm)

Battery Terminals

See battery manufacturer’s recommendations

When installing DC cables:

Make certain DC circuit breakers are turned to the off position, or fuses are removed, before proceeding.

Battery positive (+) and negative (–) cables should not exceed 10 feet (3 m) each to reduce voltage loss and other effects.

The modular construction of the GS8048A requires the use of two DC circuit breakers or fuses.

The cables for each overcurrent device must

each be sized appropriately. Alternately, a single cable or bus may be used

if sized to the minimum total ampacity. The cables listed above are for each inverter in a system. In a multiple-inverter

system, each inverter requires its own cables and overcurrent devices of the size indicated.

Install all overcurrent devices on the positive cable.

Tie, tape, or twist positive and negative cables together to reduce self–inductance. Run positive and negative cables

through the same knockouts and conduit.

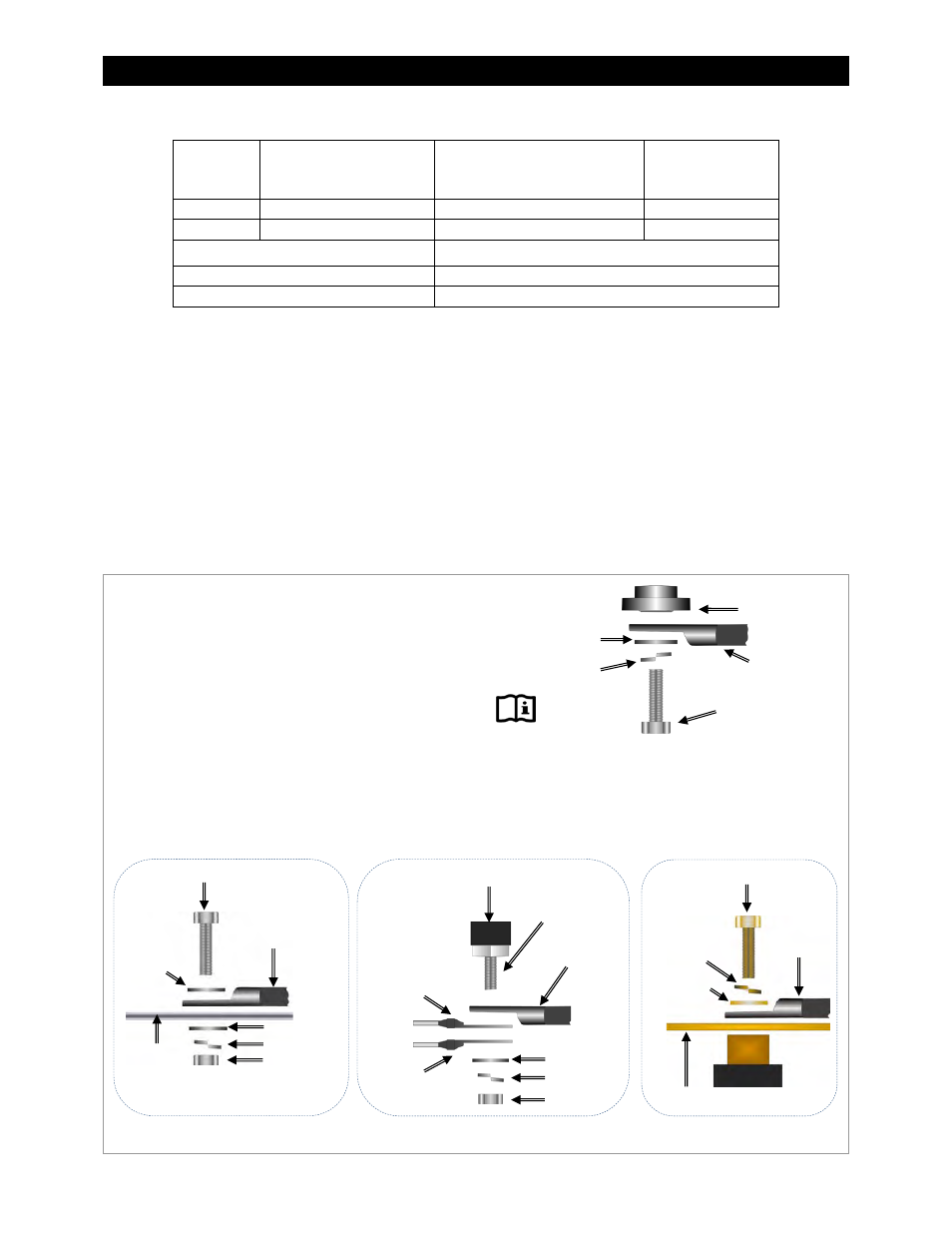

NOTE

: Do not install hardware in a different order from the illustrations shown in

Error! Reference source not found.. In

all cases the battery cable lug must be the first item installed. It must make solid contact with the surface.

Figure 16 DC Cable Hardware (Radian inverter)

If the battery cables are connected directly to the Radian

inverter, the hardware should be arranged as shown in image A.

The inverter’s battery terminal is a threaded hole which accepts

a hex bolt (provided). The battery cable lug must have a

0.79 cm (5/16") diameter hole.

If the inverter is installed with the GS Load Center (GSLC),

follow GSLC instructions for cable and hardware installation.

The hardware should be arranged according to the appropriate image below.

GSLC models used with the GS8048A inverter are equipped with a DC positive (+) plate. The plate accepts an M8 hex

bolt and nut. See image B.

GSLC models used with the GS4048A inverter do not use the DC positive plate. The cable lugs are connected to the

DC disconnect, which uses a threaded M8 stud. See image C.

All GSLC models connect the battery negative cables to the shunt, which is threaded for 3/8” bolts. See image D.

Battery Cable

Lug

Flat Washer

M8-1.25 Hex Bolt

Mounting

Surface

Lock Washer

Battery

Cable Lug

M8-1.25 Hex Bolt

Lock Washer

Flat

Washer

DC

Positive

(+) Plate

Nut

Flat Washer

GS-SBUS

Battery

Cable Lug

Flat Washer

Lock Washer

Shunt

B

DC Disconnect

Battery

Cable Lug

Battery Monitor

Ring Terminal

Charge

Controller Ring

Terminal

Flat Washer

Lock Washer

Nut

M8 Stud

C

D

A

3/8” Hex Bolt