Shift light lamp replacement, Green wire connection, Shift light rpm trip point set-up – Actron CP7905 User Manual

Page 2: Backlighting lamp substitution or replacement

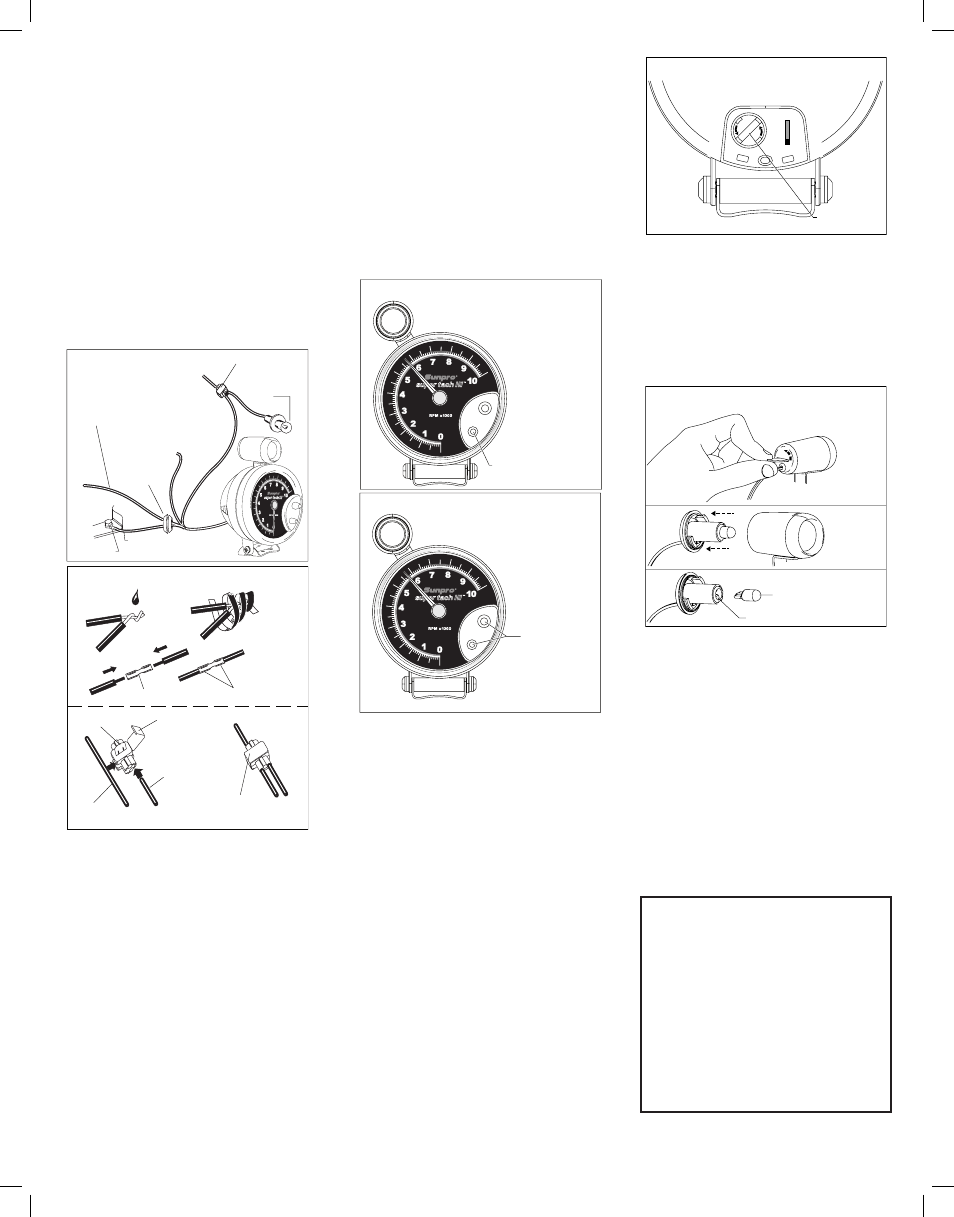

Fig. 10

STEP 1

Press and turn coin

counter clockwise to

unlock rear cap

STEP 3

Pull lamp

straight out

STEP 2

Pull rear

cap out

LAMP SOCKET

LAMP

Fig. 9

BACKLIGHTING

LAMP SOCKET

4

2

CYL.

8

6

FULL ONE (1) YEAR WARRANTY

Sunpro, a business unit of SPX Corporation, 15825 Industrial Parkway,

Cleveland, Ohio 44135, warrants to the user that this unit will be free from

defects in materials and workmanship for a period of one (1) year from the

date of original purchase.

Any unit that fails within this period will be repaired or replaced at Sunpro’s

option and without charge when returned to the Factory. Sunpro requests

that a copy of the original, dated sales receipt be returned with the unit to

determine if the warranty period is still in effect.

This warranty does not apply to damages caused by accident, alterations, or

improper or unreasonable use. Expendable items, such as batteries, fuses,

lamp bulbs, flash tubes are also excluded from this warranty.

Sunpro, a business unit of SPX Corporation DISCLAIMS ANY LIABILITY

FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES FOR BREACH OF

ANY WRITTEN WARRANTY ON THE UNIT. Some states do not allow the

disclaimer of liability for incidental or consequential damages, so the above

disclaimer may or may not apply to you. This warranty gives specific legal

rights, and you may also have rights, which vary from state to state.

SHIFT LIGHT LAMP REPLACEMENT

The External Shift Light also uses a wedge base lamp

for illumination.

To replace the Shift Light lamp, follow steps to open

the shift light (see figure 10). Remove the lamp from

its socket by pulling it straight out. Replace the lamp

with a #168 automotive lamp. If light is too bright,

replace with a lamp of less intensity such as #194 or #161.

Reassemble the shift light by reversing the steps.

BLACK, RED, AND WHITE WIRE CONNECTIONS

– ALL SYSTEMS

1. Connect the BLACK wire to the negative (-) battery

terminal, or a clean unpainted chassis ground using a

ring terminal or other suitable means (see figure 5.)

Make the following connections with wire splices, or

by an alternative method if desired (see figure 6.)

2. Connect the RED wire to any vehicle harness wire

which is energized with battery voltage, ONLY when the

ignition key is in the ON (RUN) position, NOT OFF OR

ACCESSORIES (see figure 5.)

3. Connect the WHITE wire to the instrument panel

lighting circuit that is controlled by the instrument panel

dimmer control (see figure 5.)

Some vehicles (typically imported) wire the dimmer control

into the ground side of the instrument panel lighting

circuit, as opposed to the more conventional “hot” or 12-volt

side. In vehicles which use this circuit, connect the WHITE

wire to a circuit which is energized by the headlamp switch.

VEHICLE

HARNESS WIRE

PIERCING

CLIP

Fig. 6

CONNECTOR

WIRE SPLICE

LIP UNLOCKED

TACHOMETER

WIRE

WIRE SPLICE

LOCKED

ELECTRICAL

TAPE

CRIMP ENDS

SOLDER

Fig. 5

RED WIRE

TO BATTERY

VOLTAGE

GROMMET

RING

TERMINAL

WHITE

WIRE

BLACK

WIRE TO GROUND

SEE THE

GREEN

WIRE CONNECTION

SECTION OF

THIS MANUAL

INSTRUMENT

LAMP

WIRE

SPLICE

TO DIMMER

SWITCH

GREEN WIRE CONNECTION

The GREEN wire provides the tachometer with the engine

RPM (speed) signal.

DISTRIBUTOR EQUIPPED ENGINES

Connect the GREEN wire to the negative (-) side of the

ignition coil. This terminal may also be referred to as the

TACH, TACH TEST, DEC, or ECU terminal.

DISTRIBUTORLESS IGNITION SYSTEM EQUIPPED

ENGINES

If your vehicle’s DIS ignition system has a tachometer

output lead set the switch to the 4 Cylinder position for the

4 cylinder engines and to the 6 Cylinder position for the

6 cylinder engines. Connect the tachometer GREEN wire

to the vehicle’s tachometer output lead.

If your vehicle’s DIS ignition system does not have a

tachometer output lead but allows access to the driver

wires from the vehicle computer to the ignition module,

set the switch to the 2 Cylinder position regardless of the

number of cylinders in the engine. Connect the tachometer

GREEN wire to either of the driver wires.

MULTIPLE SPARK DISCHARGE IGNITION

SYSTEM EQUIPPED ENGINES

For Multiple Spark Discharge ignition systems, connect

the GREEN wire only to the tachometer output terminal on

the ignition module. Do NOT connect to the ignition coil.

SHIFT LIGHT RPM TRIP POINT SET-UP

Some possible uses for the Shift Light are:

Engine RED LINE (maximum safe operating speed of

the engine)

Engine maximum torque RPM (for maximum

performance shifting) and desired shift speed.

NOTE: You will need both hands free to set the

tachometer (see figures 7 and 8).

•

•

Fig. 8

1. Push and hold

lower knob

To set Shift Light

trip point

2. At the same time

push and rotate

upper knob

To view Shift Light trip point

Push and hold lower knob

Fig. 7

1. Turn the ignition key to the ON position. The engine does

not have to be running.

2. Push and keep the LOWER knob depressed.

3. Push in and rotate the UPPER control knob until the

tachometer pointer indicates the RPM trip point at

which the Shift Light should turn ON.

4. Release both the LOWER knob and the UPPER

control knob.

Note: If at any time the tach pointer appears to freeze

beyond the 10,000 RPM marker: 1) Turn on the ignition

2) Push and hold both knobs 3) Turn the UPPER knob

fully clockwise and then return to the desired trip point.

BACKLIGHTING LAMP

SUBSTITUTION OR REPLACEMENT

The tachometer is supplied with a #168 wedge base

lamp. If the light is too bright, replace with a lamp of less

intensity such as a #194 or #161.

The lamp socket is located in the rear of the housing

of the tachometer (see figure 9). To remove the lamp, gently

grasp the black lamp socket (use pliers if necessary)

and twist it counterclockwise approximately 1/8 turn

until it stops. Pull the socket with lamp straight out of the

tachometer housing. Remove the lamp from its socket

by pulling it straight out. Replace the lamp. Reinstall the

socketed lamp by rotating it against the tachometer’s

internal PC board until it drops into place, and then rotate

it approximately 1/8 turn clockwise until it reaches its

mechanical stop.

0002-000-2861

Sunpro, a business unit of SPX Corporation

1-800-228-7667