Actron CP8203 User Manual

Precautions, Installation, Troubleshooting

1

VACUUM / ECONOMETER / BOOST GAUGE INSTRUCTIONS

INDICADOR DE VACIO / DE ECONOMIA/DE REFUERZO INSTRUCCIONES TENSIÓN 12 V

VACUOMÈTRE / ÉCONOMÈTRE / MANOMÈTRE DE PRESSION DE TURBO INSTRUCTIONS

These types of gauges measure the vacuum

and/or pressure existing within the intake mani-

fold of the vehicle. Different ranges or markings

cover different needs and applications. A vacuum

or econometer gauge measures the vacuum cre-

ated as the engine draws air into its cylinders. A

boost gauge measures the same vacuum as well

as the pressure when an external turbocharger

or supercharger pushes air into the engine. An

engine that is not supercharged or turbocharged

will generally have a vacuum reading between 12

and 18 Hg (inches of mercury) at idle. Check the

manufacturers specifications for more exact read-

ings for your engine at idle speed and other RPM.

All of these gauges can aid you in monitoring en-

gine efficiency, achieving the best fuel economy

and noticing engine malfunctions immediately.

PRECAUTIONS

1. Be sure the source of vacuum you pick is a

direct source and not in the brake booster or

other accessory line, otherwise the reading may

be inaccurate or unsteady.

2. Be sure your tubing and fitting connections are

complete and sealed, for a vacuum leak will

cause rough engine operation at idle, and in-

accurate readings.

INSTALLATION

For Gauges with a Barbed Fitting:

1. Find a location on your intake manifold where

you can either unscrew a plug in the manifold

or find a vacuum hose you can cut to splice in

a barbed T-Fitting.

2. From the tubing kit, either screw in the barbed

manifold fitting or splice the barbed T-Fitting

into a suitable vacuum line. This is done by

cleanly cutting the tubing and then pressing

each cut end of the tubing tightly into the op-

posing barbs of the T-Fitting.

3. Unroll a few feet of vacuum tubing and press

the end tightly into the remaining barb of the

T-Fitting.

4. Route the remaining tubing through the fire wall

into the gauge, leaving at least one 3 or larger

loop in the tubing before it enters the fire wall

and protect the tubing from any rough edges

of the fire wall. Press the tubing tightly onto

the barb on the back of the gauge.

5. Start the engine and check for proper gauge

operation. Refer to the How To Use section

on the next page.

For Gauges with 1/8 NPT (threaded) Fitting:

1. Find a location on your intake manifold where

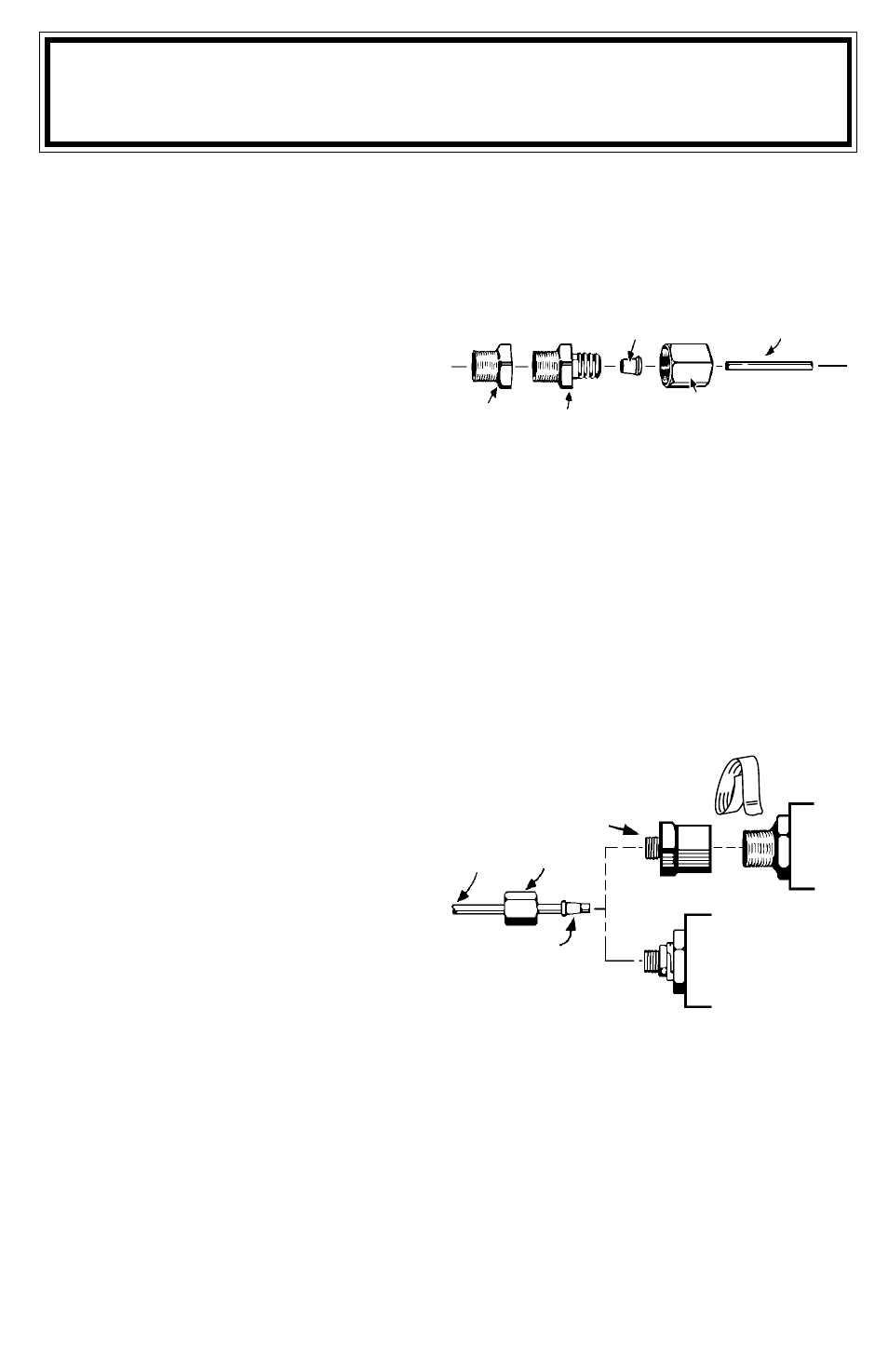

and ferrule over the end of the tubing as show

in Diagram 1.

4. Insert the tubing into the engine fitting and then

tighten the hex nut into the engine fitting.

5. Route the remaining tubing through the fire wall

to the gauge, leaving at least one 3 or larger

loop in the tubing before it enters the fire wall

and protecting the tubing from any rough edges

of the fire wall.

6. If the hex nut adapter is not attached to the

gauge, then wrap Teflon tape around the

adapters threads and attach the hex nut

adapter. Attach the tubbing as in Steps 3 and 4.

Refer to Diagram 2.

7. Complete the mounting of the gauge.

8. Start the engine and check for proper gauge

operation. Refer to the How To Use section

on the next page. For boost gauges, you will

need to consult manufacturers specifications

for the RPM and pressure values that provide

the maximum boost and for the RPM value

that transfers to boost from vacuum.

TROUBLESHOOTING

1. If your engine idles roughly, check the tubing

and fittings for leaks. Sealing tape or compound

can usually be used to solve these leaks.

2. If the gauge vacuum readings changes when

you can screw in the engine fitting directly or

using the adapter included with the gauge.

Manifolds often have removable plugs.

2. Screw in the adapter (if needed) and engine

fitting into the manifold at the location you se-

lected.

3. Uncoil a few feet of tubing and slide a hex nut

Diagram 1

FERRULE

TUBING

ADAPTER

ENGINE

FITTING

HEX NUT

PARA NOMBRE, DOMICILIO Y TELEFONO DE IMPORTADOR: VER EMPAQUE.

Diagram 2

HEX NUT ADAPTER

HEX NUT

TUBING

FERRULE

1/8 NPT

GAUGE

COMPRESSION

FITTING GAUGE

TEFLON TAPE