Installation testing with the fuel system test kit, Disconnecting fuel pressure gauge, General fuel pressure diagnostics – Actron KM2529 User Manual

Page 2: Caution, Figure 2, Customer service

100

200

300

400

10

psi

40

60

kPa

50

30

20

INSTALLATION

TESTING WITH THE FUEL SYSTEM TEST KIT

NOTE: Before beginning any test-

ing, perform diagnostic procedures

described in vehicle service

manual to eliminate other possible

causes of driveability problem.

Compression and ignition prob-

lems may imitate fuel injection sys-

tem problems.

Before proceeding with fuel pres-

sure testing, read and understand

all safety guidelines and perform all

pre-testing checks.

1. Place end of 6-ft. bleed-off hose in

an approved fuel container. Bleed-

off hose must remain in container

until testing is complete.

2. Turn all accessories OFF (i.e. ra-

dio, A/C, blower fan, headlights,

windshield wipers, etc.)

3. Turn ignition key ON.

Perform the following checks:

Pressurize fuel system by cycling

ignition ON and OFF every ten

seconds until fuel pressure is at

manufacturers specifications

(check vehicle service manual for

your particular application).

Check fuel system for leaks. If

leaks are found, turn ignition key

OFF and clean up fuel immedi-

ately!

If fuel pressure is not within

manufacturers specifications,

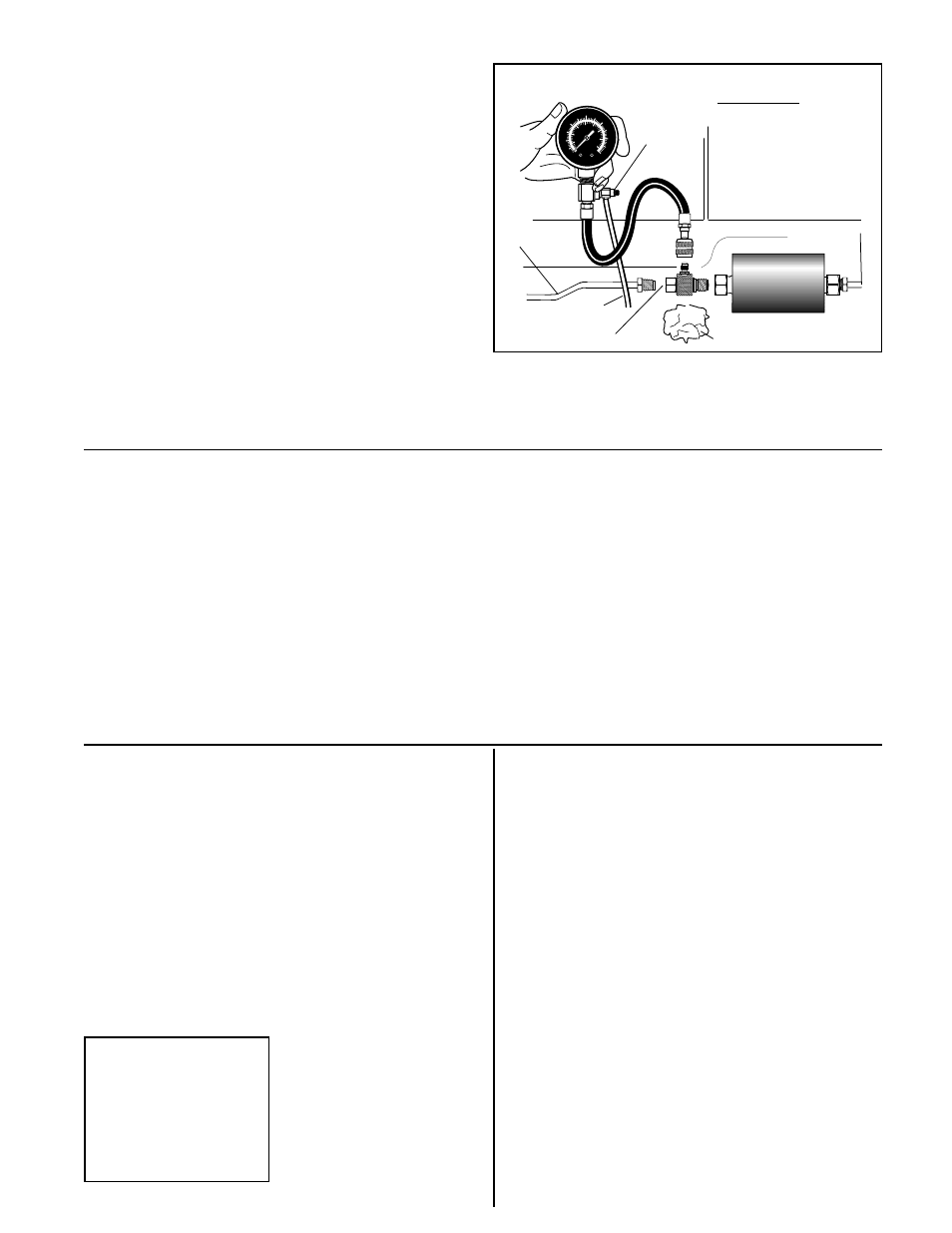

PRESSURE

RELIEF

BUTTON

BLEED-OFF

HOSE

FUEL LINE

from TANK

GM TBI ADAPTER

SHOP TOWEL

FUEL FILTER

CAUTION:

ALWAYS MAKE SURE

THAT BLEED-OFF HOSE

DRAINS INTO A

2-GALLON OR LARGER

APPROVED

CONTAINER!

Figure 2

WARNING: Some vehicles may

have more than one fuel pump.

Failure to deactivate all fuel

pumps can result in spilled fuel,

fire, or other hazardous condi-

tions that could cause vehicle

damage, personal injury, or

death.

CAUTION: The information pro-

vided here is not intended as a

substitute to the procedures

given in the vehicle service

manual. Always follow the

manufacturers instructions

when working on fuel systems.

2. At the location specified in vehicle

service manual, disconnect the fuel

line. Use a shop towel to catch any

released fuel. Figure 2 shows the

typical location at a fuel filter. If filter

is attached with a clamp, remove

the clamp and then remove the filter

if necessary. If the filter is dirty or is

suspect in any way, replace it.

3. Attach the special fuel tester

adapter to the fuel filter, and then

attach the fuel line to the adapter

as shown in Figure 2. Tighten all

fittings finger tight and then tighten

gently 1/2 turn with wrenches.

For GM vehicles without a

fuel access valve test port

on the fuel rail:

When working on fuel system lines

and components, always make sure

to keep a dry chemical fire extin-

guisher ready. Never put water on a

fuel or electrical fire. Keep a supply of

clean dry shop towels handy to absorb

leaks and spills when disconnecting

fittings, lines, and hoses. Also have a

2-gallon or larger approved fuel con-

tainer ready to collect fuel when test-

ing or bleeding the fuel lines.

Install the fuel pressure tester as fol-

lows:

1. Relieve fuel system pressure by

following the instructions given in

the vehicle service manual. On

most vehicles this is done by

removing

the

fuel

cap,

disconnecting or deactivating the

electric fuel pump(s), and running

the engine for about 30 seconds

until it stalls.

FUEL LINE to

ENGINE

cycle ignition key 2 or 3 more

times. If fuel pressure is still not

within specification, service ve-

hicle according to vehicle service

manual.

4. Start engine and let idle.

If test vehicles fuel system uses

a

vacuum

actuated

(compensated) fuel pressure

regulator, then fuel pressure

should drop 3-10 psi, depending

on manifold vacuum.

If test vehicles fuel system uses

a fuel pressure regulator without

a vacuum port, then fuel pressure

should remain constant during

both key-on-engine-off

and idle.

• Read fuel pressure from dial

face.

• If fuel pressure is not within

manufacturer ’s specification,

then service vehicle according to

vehicle service manual.

• When repair is complete and idle

fuel pressure is within

manufacturer ’s specification,

then proceed to Step 5.

5. Turn ignition key OFF.

6. Disconnect fuel pressure gauge as

described in the following section.

DISCONNECTING FUEL

PRESSURE GAUGE

1. Verify that 6-ft. bleed-off hose is still

in an approved container for fuel.

2. Fully DEPRESS and HOLD the

pressure relief button until dial face

pointer is resting on stop pin.

CAUTION: Pressurized fuel will

spray out of bleed-off hose and into

approved container.

3. Shake bleed-off hose to make sure

that all fuel has gone into approved

container.

4. Remove gauge hose from fuel line

adapter fitting:

Wrap a shop rag around fuel line

adapter fitting in case a small

amount of fuel drips out while

unscrewing test adapter.

Unscrew fuel pressure gauge

from fuel line adapter fitting.

Wrap a shop rag around end of

fuel pressure gauge hose to catch

any fuel dripping from hose.

Remove bleed-off hose from

approved fuel container and hold

gauge hose over container so any

remaining fuel will drip into

container.

5. After relieving fuel system pressure,

disconnect fuel line adapter and

reconnect fuel lines as described

in vehicle service manual. Use

correct fuel line fitting tools. Clean

up any spilled fuel immediately!

6. Store shop rags in an approved

container so they cannot cause

personal injury or a hazardous

situation.

7. Store fuel pressure gauge in a well-

ventilated area where it cannot

cause personal injury or a

hazardous situation.

GENERAL FUEL PRESSURE

DIAGNOSTICS

4. Attach the 42-inch hose and pres-

sure gauge assembly to adapter

top fitting and tighten fitting until fin-

ger tight.

Checking fuel pressure is an essen-

tial part of fuel injection system

troubleshooting. High fuel pressure

will make an engine run rich, while

low fuel pressure will make an en-

gine run lean or not at all. In some

cases, low fuel pressure can cause

additional damage such as burned

pistons, valves, spark plugs, or

blown head gaskets.

Fuel pressure readings which are

higher than manufacturers speci-

fications are generally caused by a

problem in the fuel return line com-

ponents. Conversely, fuel pressure

readings which are lower than

manufacturers specifications are

generally caused by a problem in

the fuel pressure line components.

If fuel pressure readings are not

within manufacturers specifications,

refer to a vehicle service manual for

step-by-step diagnostic procedures

which will pinpoint the faulty compo-

nent for each specific vehicle.

Customer Service

For product information or customer

service please call 1-800-ACTRON-7

(1-800-228-7667) or fax anytime at

(216) 651-2388.

For technical support call:

1-800-253-9880

Internet home page:

http://www.actron.com

Possible causes of high fuel

pressure readings may include:

Faulty fuel pressure regulator.

Restriction in fuel return line.

Faulty fuel line couplings at fuel

tank or fuel pickup.

Sticking or sluggish fuel

injectors.

Possible causes of low fuel pres-

sure readings may include:

Clogged or restricted fuel filter.

Restriction in pressure line.

Faulty fuel pump(s).

Faulty fuel pump relay.

Blown fuel pump fuse.

Faulty fuel pump wiring.

Clogged or restricted fuel pump

filter.

Faulty fuel pressure regulator.

Leaking fuel injectors.

Faulty fuel line couplings at fuel

tank or fuel pickup.

0002-002-2350