Distributor vacuum advance mechanisms, Test results, Fuel pump testing – Actron KAL2512 User Manual

Page 4

3. Return idle screw and idle air bleed

screws to original positions, if required.

4. Re-enable the ignition system

5. Reconnect wire to idle stop solenoid.

6. Reconnect all hoses and vacuum lines.

7. Reinstall PCV valve.

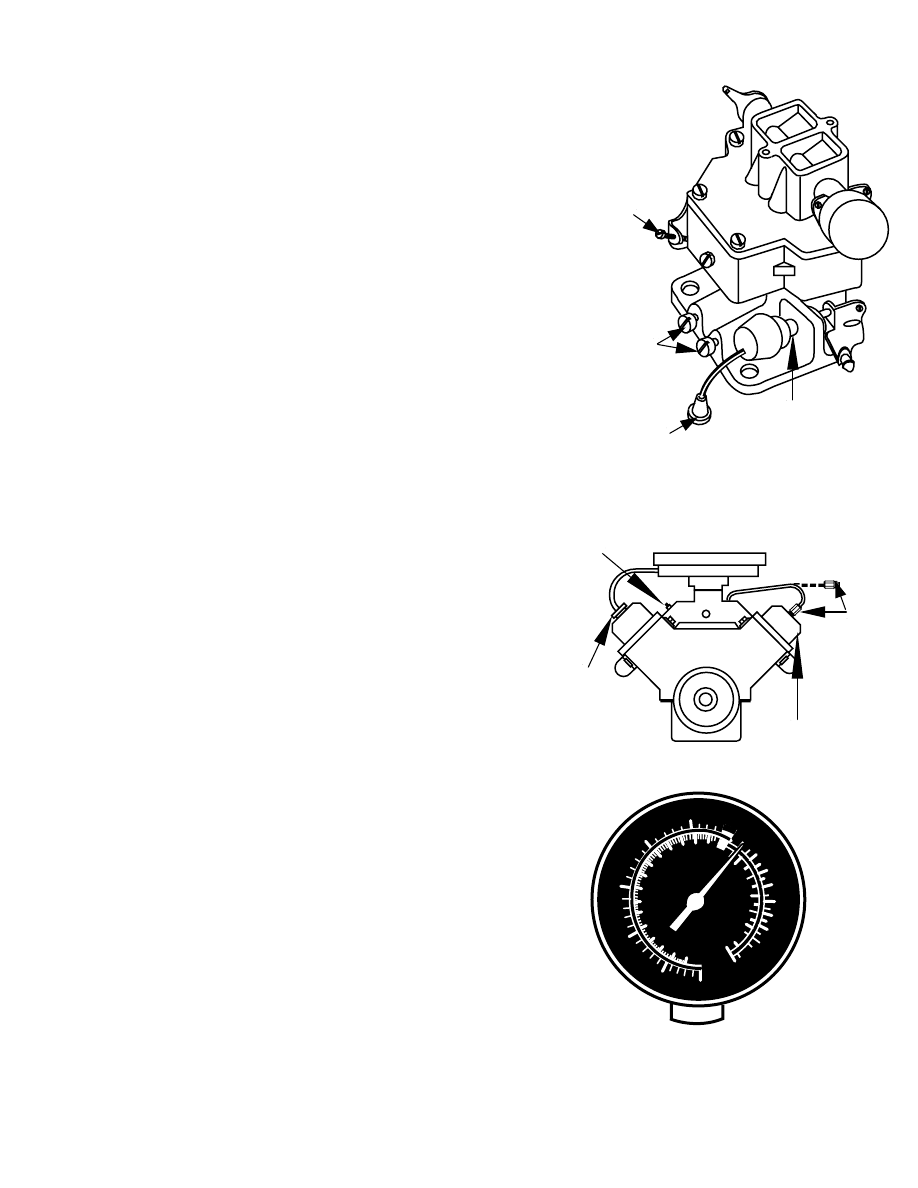

Distributor Vacuum Advance

Mechanisms

1. Disconnect hose from distributor

2. Insert a tee connector in line with

hose and another back to distributor.

3. Connect gauge to the tee connector.

4. Start engine and note vacuum at idle.

5. Slowly increase RPM noting vacuum

pressure.

Test Results

2 possible results are:

A. Vacuum manifold pressure should

drop as engine speed is increased

per vehicle manual

B. If vacuum manifold pressure does not

change or changes very little check for:

Vacuum hose being opened or

cracked

Diaphragm in advance mechanism

punctured.

NOTE: Vacuum reading can appear

normal during the above test but still

have a bad advance mechanism that is

frozen due to corrosion or dirt.

Fuel Pump Testing

Fuel Pump Testing can be done using

the 0-10 psi scale on the gauge. Make

sure to follow manufacturers

instructions exactly and follow all safety

precautions.

©2004 Actron

Manufacturing Company. All rights reserved.

0002-003-1862

0

Engine

Vacuum

5

10

15

20

25

30

10

9

8

7

6

5

4

3

2

1

0

1

2

3

4

5

6

7

Fuel

Pump

psi

Idle

Speed

Screw

Idle

Mixture

Screw

Electrical

Connector

Idle Stop

Solenoid

Air Cleaner

Manifold

Vacuum

Closed

Breather

Cap

Rocker Arm

Valve Cover

PCV Valve

Using Fuel Pump Scale