Pypes Performance Exhaust HDR76SK User Manual

Hdr76s/ hdr76sk

Thanks again for purchasing your new stainless steel Pypes Performance Ex-

haust Long tube headers. Please be sure to confirm all the components in the

kit were received in your shipment before beginning installation. If you find any

components missing, please contact our office at 800-421-3890 for replace-

ment. Technical assistance is available both on line at www.pypesexhaust.com

or by calling 800-421-3890

Pypes exhaust are designed for the savvy home installer but highly recommends hiring a professional, one that is familiar with the

installation of high performance exhaust products. Headers are designed to increase the performance of your vehicle, and as such

are designed differently than your stock exhaust system. Extra care must be taken to ensure that hoses, cables, electrical lines,

fuel lines, hydraulic lines, or any other objects are not in contact with, or located too close to your installed system.

Work Safe: When supporting a vehicle on jack stands, be sure the ground surface

is level and solid, hot asphalt will not support jack stands. Double check your place-

ment before sliding under the vehicle.

Note: Many factors may affect the installation: broken, worn or aftermarket motor

mounts, aftermarket suspension components, bent frame or chassis components

from accidents, different engines or cylinder heads.

Attention: These items have a highly polished finished which can be marred or

scratched during installation. If these products need to be returned and are dam-

aged in any way, you will be charged a 20% restock/polish fee.

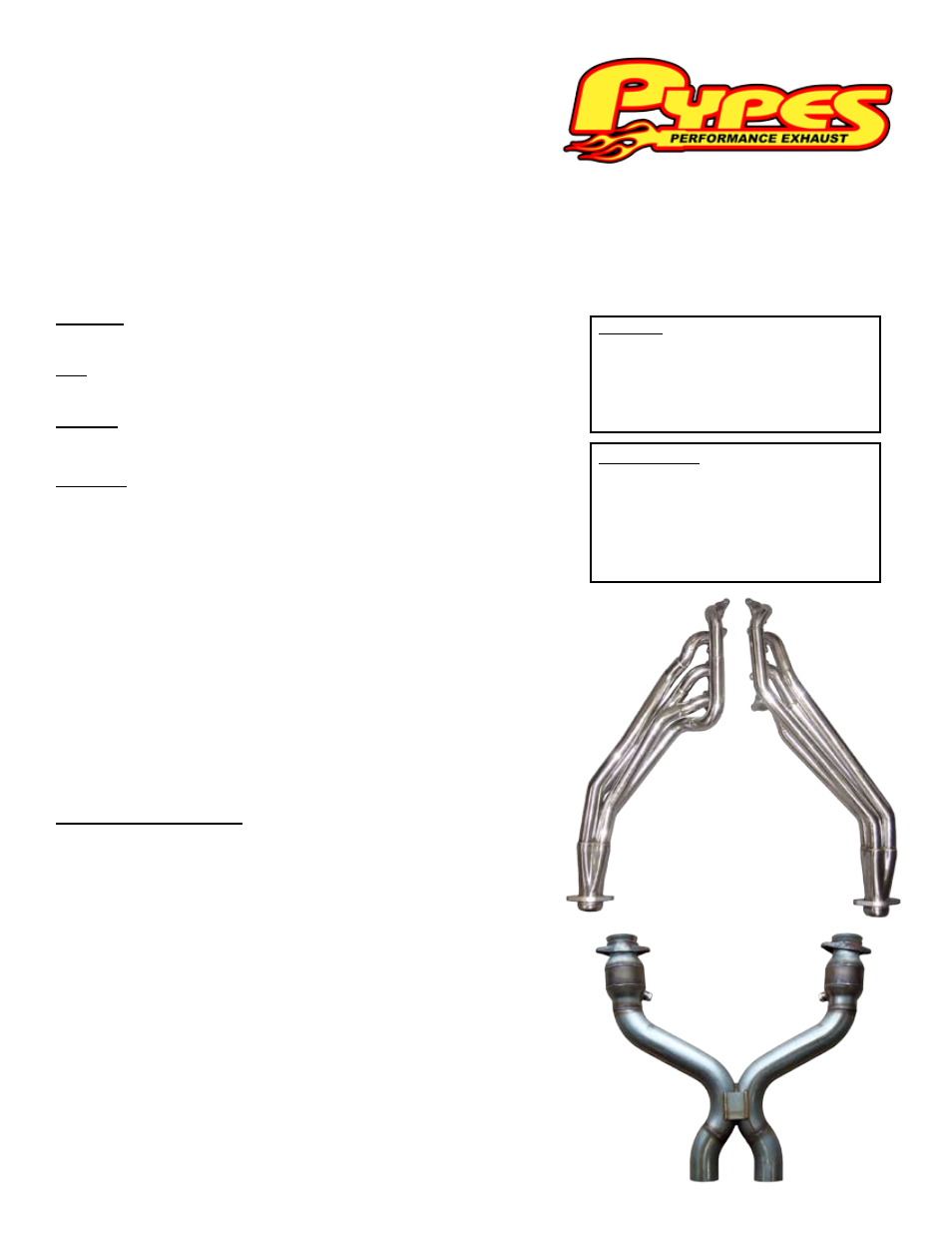

HDR76S/ HDR76SK

2011-12 Mustang Long tube Header Kits

HDR76S: 2011-12 Mustang Long tube Header

HDR76SK: 2011-12 Mustang Long tube Header & X-pipe/H-pipe Kit

Pypes Performance Exhaust

2705 Clemens Road Bldg 105A Hatfield, PA 19440

800-421-3890 (voice) 267-638-3507 (fax)

www.pypesexhaust.com

Disclaimer: By installing any PPE products, you indicate that you have read

the following and agree to these terms:

The purchaser is responsible for following the instructions and safety guide-

lines set by PPE.

PPE assumes no responsibility for any damages from improper installation,

abuse, lack of care or incompatibility with other manufacturers products.

The purchaser is responsible for any damage to the products if returned.

These products are manufactured using 304 polished stainless steel. Ex-

haust heat will turn the finish to a bluish/gold color. This is normal and not a

cause for a warranty claim or return.

Warranty: PPE will repair or replace the product at no charge (See en-

closed warranty card). We are not responsible any labor charges or shipping

fees.

•

•

•

•

•

Requires Tools:

7/8” open end wrench or O2 sensor socket

Assorted metric sockets and wrenches

Ratchet and extensions

Miscellaneous hand tools

Floor jack and jack stand or hydraulic lift

Anti-seize

While this installation can be done on the floor with the use of jack stands we

strongly recommend that this job be completed utilizing a hydraulic lift. You will

need 24 to 30 inches of ground clearance to slip the header into position from

the bottom of the vehicle. Please allow the engine to cool for a minimum of 90

minutes before starting the removal and installation steps. The use of safety

goggles will protect you from falling debris that may be dislodged from the bot-

tom of the vehicle during the removal and installation process.

Stock system removal:

Begin by locking the steering column in place so it cannot rotate once the

steering shaft is disconnected in a later step. Failure to do so may result in

damage to the steering wheel controls if your vehicle is so equipped.

Remove the battery terminals by starting with the negative cable first fol-

lowed by the positive. We have found no need to remove the battery and tray

but if you choose to it will give you more room to remove and install the top

side manifold bolts.

Remove the strut tower brace bar if your car is so equipped along with the

engine cover.

Loosen the clamp that holds the air inlet tube to the mass air sensor and

remove the tube from the mass air. Again we found no need to remove the

factory air box but if you feel the need it will gain you better access to the

manifold bolts.

Remove the driver and passenger side O2 connector where it’s secured on

the back of the block at the bell housing stud to allow the sensor to be relo-

cated further back.

Remove the outside nuts holding the cats to the manifolds on both sides as

well as the nuts on top of the engine mounts.

At this time you can raise the car with either jack stands of a hydraulic lift.

Again we strongly recommend the use of a lift for the following steps.

Loosen and remove the 2 rear O2 sensors in the H-pipe and mark their

locations so they can be reinstalled in the same positions in your new x-pipe.

•

•

•

•

•

•

•

•

Parts List:

1 Set Pypes long tube headers

1 Set (16) header bolts with washers

4 each collector bolts with washers and nuts

2 each O2 extension cables

1 X-pipe or H-pipe (HDR76SK only)

HDR76S

XFM76