Nitrous Express N-TERCOOLER SYSTEM User Manual

Page 2

2. The supplied wide-open throttle switch is univer-

sal in design and can be mounted in a variety of

positions. The mounting plate is designed to be

easily bent cut or twisted to work in any applica-

tion. The trigger arm on the micro switch may be

bent twisted or cut to aid in ease of installation.

3. The best power source for the system is the “Posi-

tive” post on the battery. Do not try to “Splice”

into the factory wiring harness for a power supply,

this will not have adequate amperage to operate

the solenoid.

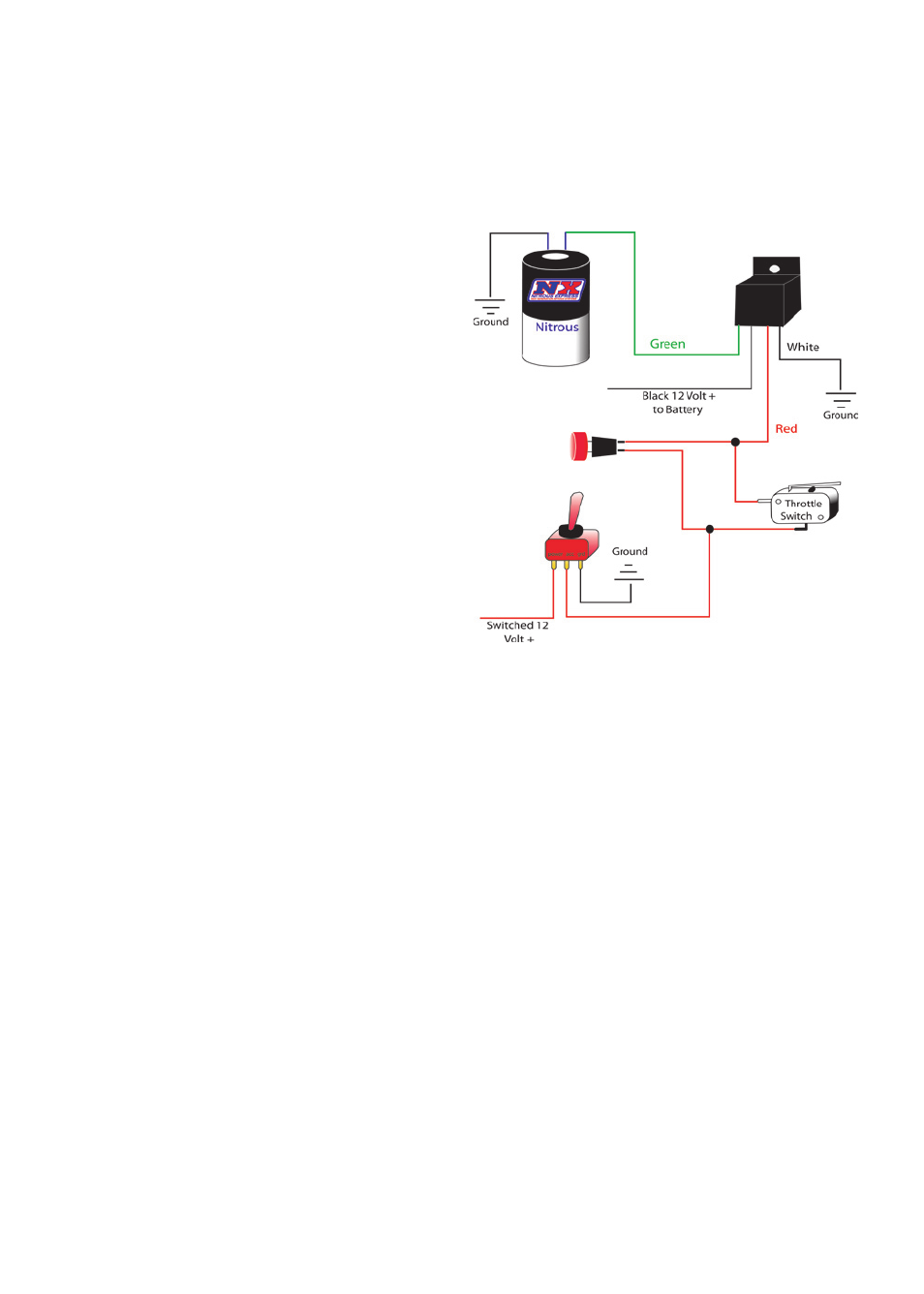

4. Follow diagram “C” when wiring the system, the

relay must be used in all applications.

5. Solder all connections for a permanent trouble

free installation.

6. The solenoid is rated only for intermittent duty.

Do not engage solenoid for more than 20 con-

tinuous seconds. Solenoids that have “burned or

scorched” electro-magnets will not be replaced

under warranty.

COMPLETING AND TESTING THE SYSTEM

1. After all components have been assembled on the

vehicle and each piece has been verified for cor-

rect installation and the wiring has been rechecked

and verified to be correct, it is time to test the

system.

2. Do not open the bottle valve at this time.

3. Reconnect the negative battery cable.

4. Using the red, lighted toggle switch “Arm” the

nitrous system.

5. Test the solenoid operation by “Engaging” the

activation or WOT switch. The solenoid should

“Click”. If it does not, re-verify all electrical con-

nections and wiring diagrams.

6. Open the bottle and check all connections for

leaks. If “ice” appears on any connection this

indicates a leak. Retighten any fitting or connec-

tion that leaks and recheck.

7. Choose a suitable testing area, your local racetrack

is the best choice. Drive the vehicle to verify all

operations are normal and the throttle linkage is

operating properly.

8. Pre-stage the vehicle, arm the system, purge the

air from the supply line, if an optional purge valve

is used, using 3 one-second bursts from the purge

button. Stage and launch the vehicle.

9. Make a full throttle pass and shut the engine off,

check all spark plugs to be sure the decrease in

inlet temperature has not resulted in a lean condi-

tion. If a lean condition is detected adjustments

must be made in the engine fuel curve.

WIRING DIAGRAM