Assembly and installation instructions, Prepare rough opening – JELD-WEN JII020 Premium Aluminum (A-500) and Premium Atlantic Aluminum Sliding Patio Doors User Manual

Page 5

ASSEMBLY AND INSTALLATION INSTRUCTIONS

for Premium Aluminum (A-500) and Premium Atlantic Aluminum Sliding Patio Doors (JII020)

5

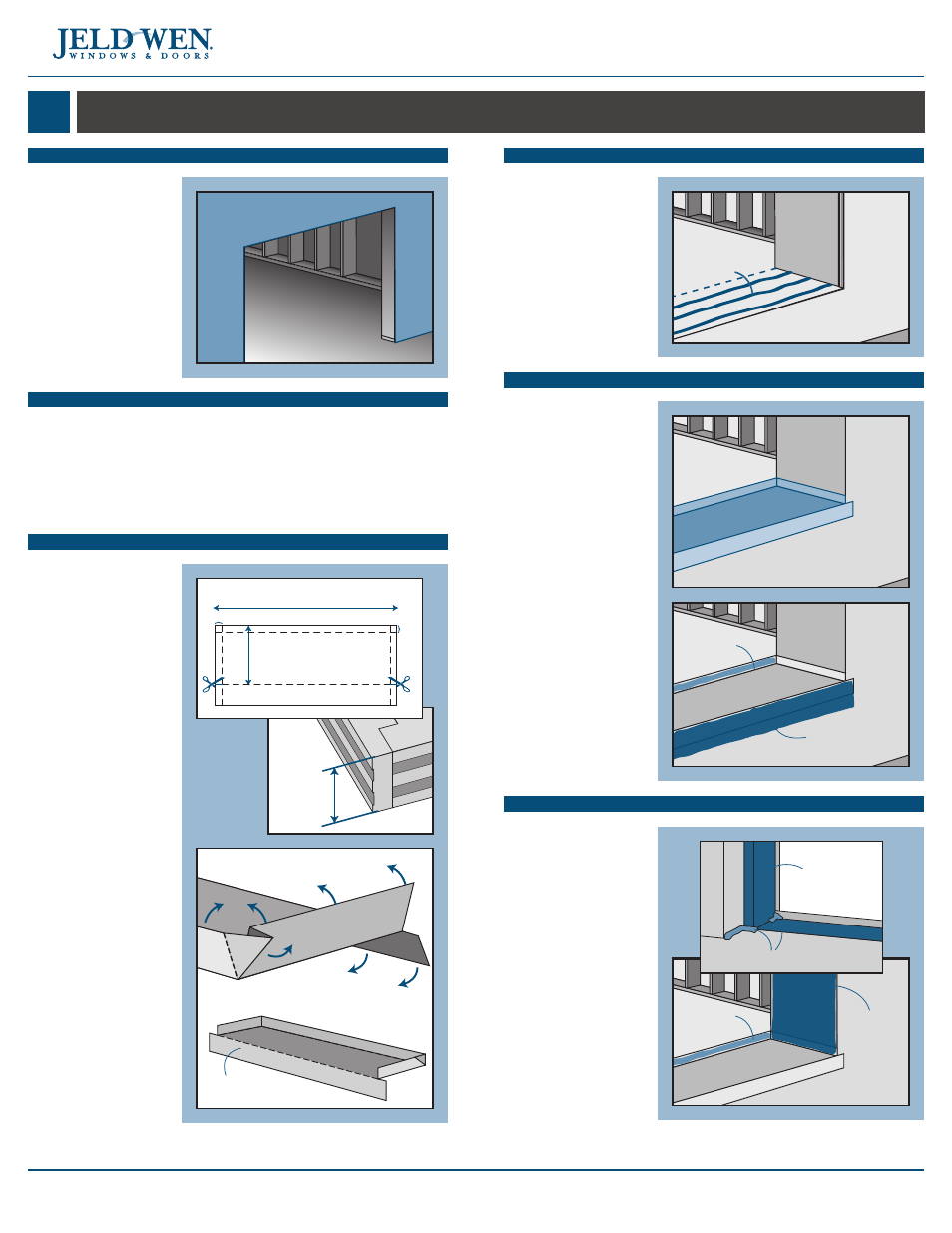

PREPARE BUILDING WRAP

(For masonry/block wall

construction, skip to SILL

PANS)

Trim building wrap flush

with the edge of the

rough opening at the

head and sides.

SILL PANS

(For a recessed sill pocket, skip to COMPLETE OPENING PREP)

The sill can be prepared using one of two methods: We recommend

SureSill™ Sloped Sill Pan™ available from SureSill at www.suresill.com,

building supply stores, and some manufacturing locations or fabricate

a sill pan on site. If installing a SureSill™ sill pan, follow SureSill™'s

instructions for installation and skip to section 5 “INSTALL FRAME“. If

fabricating a sill pan on the job site, follow the instructions below.

JOBSITE FABRICATED SILL PAN

(For a recessed

sill pocket, skip

to COMPLETE

OPENING PREP)

Note!

If using self-

adhesive flashing in

place of a metal pan,

the flashing must be a

minimum of 40 mils and

have a proper back dam,

such as a metal angle.

Use primer if adhering

to concrete.

• Cut a piece of sheet

material to the length

shown.

• Lightly crease folding

lines 1/2" in from the

two short sides and

one long side.

• Measure the width

of the exterior edge

of the frame and add

9/16".

• Take this distance from

the back edge of the

sheet material and

lightly crease a folding

line.

• Cut 1/2" in at this line

on both sides of the

sheet material.

• Fold the three back

sides up to make a

3-sided box.

• For step-down

landings, fold the

front flap down. For

continuous slabs, remove the front flap.

INSTALL SILL PAN

Note!

If installing

a metal sill pan on

concrete, the bottom

surface must be covered

with self-adhesive

flashing.

• Set the sill pan in place

pressing it down firmly

into the sealant. Use

a J-roller if necessary

to ensure a smooth,

secure seal.

• Apply a 3/8"

continuous bead of

sealant across the sill

pan back dam.

• For step-down landing

apply a layer of liquid

flashing across the

lower lip of the sill

pan, joining it to the

face of the foundation.

PREPARE ROUGH OPENING

4

Frame

width

+9/16"

Length of rough opening sill plus 1"

1/2"

1/2"

Fold sides and back up

Fold corner

forward

Fold front

flap down

PREPARE SILL

• Set the sill pan in place

and mark a line across

the back of the sill pan

with a pencil as shown.

Remove sill pan.

• Apply three 3/8" beads

of sealant between the

marked line and the

exterior edge of the

rough sill.

Sealant

Sealant

COMPLETE OPENING PREP

Waterproof the rough

opening with one of the

following methods:

• Wrap the buck or stud

completely with self-

adhesive flashing, then

seal the joint between

the flashing and the

structure, and at the

corners as shown.

OR

• Apply liquid applied

flashing in a smooth

1/16" thick layer

covering the exterior

face of the structure

in a 6" width. Apply

1/16" thick layer

to cover the entire

surface of the head and jambs, extending onto the sides of the sill

pan or across the entire surface of the sill pocket.

Liquid

flashing

For continuous

slab, remove flap

Sealant

Self-

adhesive

or liquid

flashing

Self-adhesive

flashing

Sealant

Measure

frame

width