JELD-WEN JII020 Premium Aluminum (A-500) and Premium Atlantic Aluminum Sliding Patio Doors User Manual

Page 3

ASSEMBLY AND INSTALLATION INSTRUCTIONS

for Premium Aluminum (A-500) and Premium Atlantic Aluminum Sliding Patio Doors (JII020)

3

MATERIALS AND TOOLS

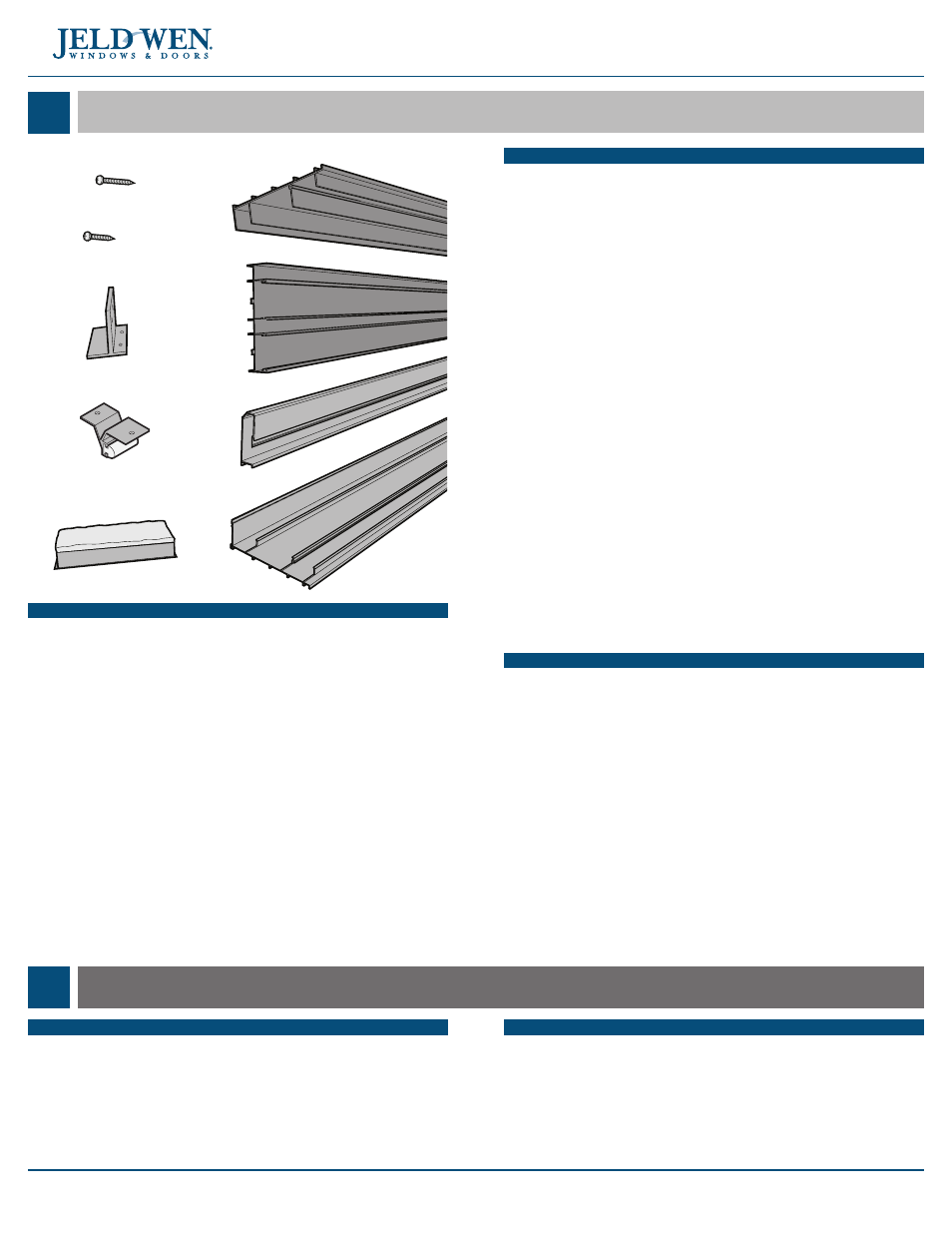

PARTS (INCLUDED WITH PATIO DOOR)

A #8 x 1" Phillips pan head sheet metal screw

B #8 X 3/4" Phillips pan head screw

C Offset T clip (DP50 / DP80 doors only)

D Panel bumper

E Adhesive weather strip pad

F Head frame

G Left and right side frame

H Sill riser (DP 65/80 doors, only)

I Sill track

Items not shown:

- Handle package

- Door panel(s)

- Screen – (optional, on some configurations)

NEEDED MATERIALS

Note!

Follow all material manufacturers’ instructions for proper use

and compatibility. When using flashing, spray adhesive/primer, sealant

and foam products, we recommend using the same manufacturer and

verifying compatibility.

• Sealant: We recommend OSI

®

QUAD

®

Max Sealant or equivalent. This

can be used in any application and can be painted or ordered in a

color matched product, if desired.

• Non-compressible or water degradable shims, such as high-density

plastic or composite.

• Backer rod 1/8" larger than the widest portion of the gap (used in

conjunction with sealant bead).

• Liquid applied flashing (Protecto Wrap LWM 200 or equivalent).

• 4", 6", or 9" (as required by local code and window configuration)

wide self-adhesive flashing: We recommend OSI

®

QUAD

®

Butyl

Flashing Tape or equivalent.

For installation in sheathed wall or open stud construction:

• #8 x 1 1/4" corrosion-resistant, flat-head screws; (length of screw must

penetrate at least 1" into the framing).

For buck framing in a concrete (masonry) structure:

• 3/16" diameter self-tapping concrete screws (Tapcon

®

, or equivalent);

length of screw must penetrate at least 1 1/4" into the concrete

For step-down and Continuous Slab landings:

• Sill pan: It is best practice to use a pre-formed, rigid, positively sloped,

pvc pan that provides continuous support. We recommend using

SureSill™ Sloped Sill Pan™ , manufactured by SureSill™, Ltd. An

alternative would be a non-sloped pre-formed sill pan or one can be

fabricated on site from self adhesive flashing, metal or vinyl sheet

material with the proper tools and materials.

NEEDED TOOLS

• Cutting shears (sill pan)

• Tape measure

• Utility knife

• Level (4' minimum

recommended)

• J-roller

• Caulking gun

• Drill with bits (assembly)

• Construction stapler

• Putty knife

• Phillips screwdriver

• Hammer drill and masonry bits

for masonry applications

A

D

E

F

G

H

I

REMOVE PACKAGING

Remove packaging materials.

1

REMOVE PACKAGING AND INSPECT DOOR

C

B

INSPECT DOOR

• Cosmetic damage

• Included parts (See Parts List above)

• Correct product (size, color, number of panels, grid pattern, glass type,

etc.)

If any of the above represents a concern, BEFORE installing, contact

your dealer or distributor for recommendations.