JELD-WEN JII031 Aluminum Windows without Nailing Fin User Manual

Page 3

INSTALLATION INSTRUCTIONS

for Aluminum Windows without Nailing Fin (JII031)

3

REMOVE PACKAGING

Remove shipping materials such as corner covers, shipping blocks or

pads. If there is a protective film on the glass, do not remove it until

installation and construction are complete.

INSPECT WINDOW

• Cosmetic damage

• Product squareness (diagonal measurements not more than 1/8"

different)

1

2

3

REMOVE PACKAGING AND INSPECT WINDOW

INSPECT ROUGH OPENING

PREPARE MASONRY/BLOCK WALL

• Correct product (size, color, grid pattern, handing, glazing, energy-

efficiency requirements, etc.)

If any of the above conditions represent a concern, or if you expect

environmental conditions to exceed the window's performance rating,

do not install the window. Contact your dealer or distributor for

recommendations.

• Verify the width

and height of the

window are each

1/2" smaller than

the rough opening

width and height.

• Verify the rough

opening is square.

The (A) and (B)

measurements

above should be

the same. Maximum

allowable deviation

from square for

windows over 20 sq.

ft. is 1/4" and for

windows under 20

sq. ft. is 1/8".

• Verify the rough opening is level and plumb (C) and (D). The

maximum allowable deviation is 1/8".

• The rough opening sill must not be crowned or sagged (D). A 5

degree

sloped sill is recommended.

• Verify the exterior face of the rough opening is a single plane (E) with

less than 1/8" twist from corner to corner.

• Verify the rough opening is structurally sound.

• Correct any deviations before installing the window.

Installation into masonry begins with section 3 “PREPARE MASONRY/

BLOCK WALL”; installation into a stud-framed wall begins with section

4 “PREPARE STUD-FRAMED WALL.”

Verify Square, Level, and Plumb

A

B

D

C

E

Note!

This section

applies to installations

into a masonry wall

only. For installations

into a stud-framed

wall, begin with

section 4, “PREPARE

STUD-FRAMED WALL.”

If installing a window

into a masonry wall

without a buck, cover

the entire rough

opening surface with

liquid applied flashing

or self-adhesive

flashing in the same

manner as the following instructions for a buck.

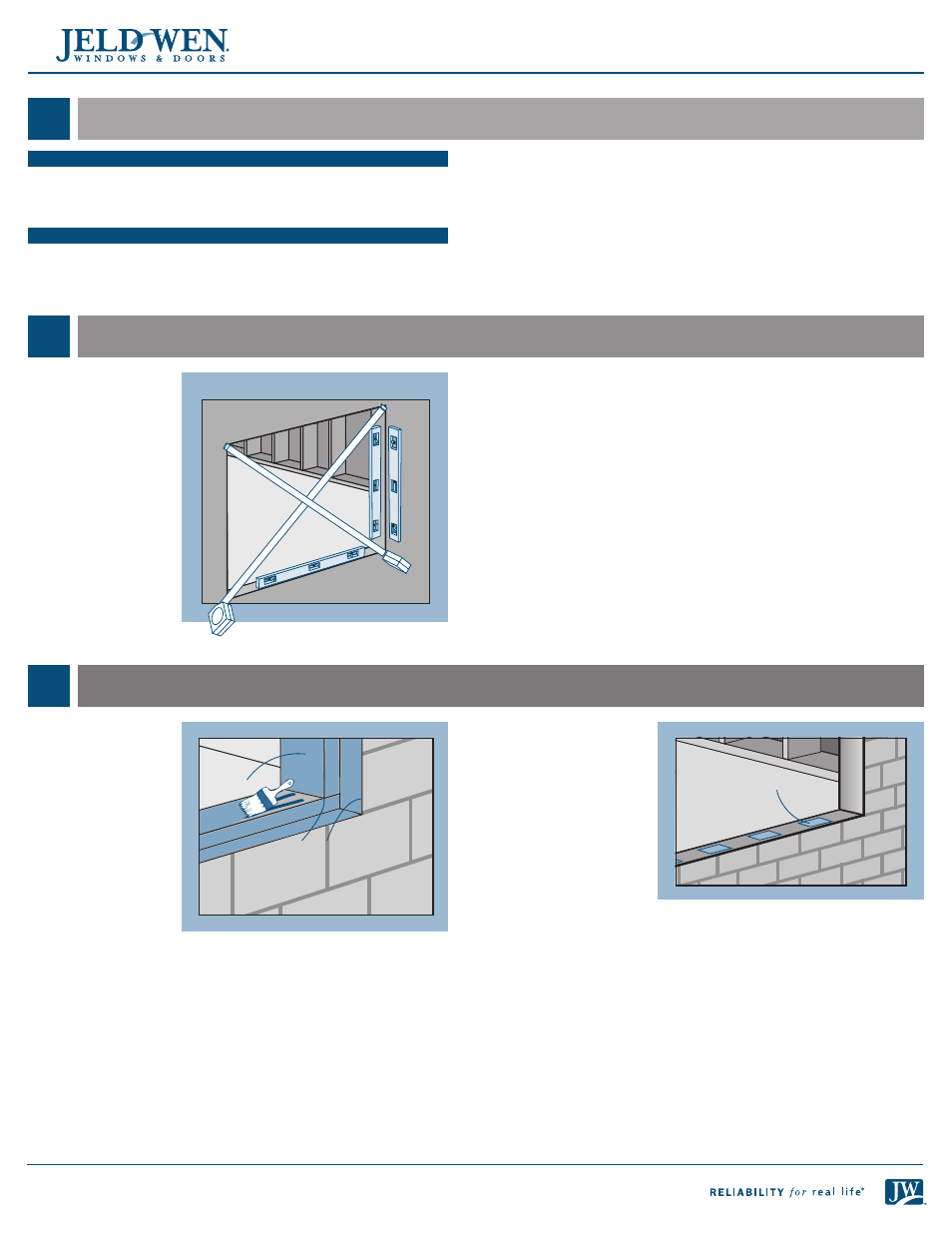

1. Seal any joint larger than 1/16" in the buck and between the buck

and the concrete/masonry with sealant.

2. Cover the buck and the surrounding concrete/masonry at the head

and jambs with liquid applied flashing as shown.

3. If installing into a four-sided buck, seal the sill in a similar manner.

Note!

Shims must be

at least 1/2" shorter

than the depth of the

window sill, should

level the rough

opening sill and be no

more than 1/4" thick.

4. Shim the sill 4"

from each corner,

at 8" intervals,

and on both sides

of mull joints

with non water-

degradable or compressible shims. Secure shims with sealant.

End of masonry instructions, SKIP TO SECTION 5, “INSTALL WINDOW.”

Liquid

applied

flashing

Sealant joints

Shim