ididit Repair of an Unseated ididit Steering Column User Manual

ididit For the car

PROPERTY OF

ididi

T, inc

PROPERTY OF

ididi

T, inc

PROPERTY OF

ididi

T, inc

PROPERTY OF

ididi

T, inc

PROPERTY OF

ididi

T, inc

PROPERTY OF

ididi

T, inc

ididit inc. 610 S. Maumee St. 49286 Tecumseh, MI PH: 517-424-0577 FAX: 517-424-7293

www.ididitinc.com

Repair of an Unseated ididit Steering Column

For Part Number’s 2620100010

Instruction #: 8000010055

REV 12/12

Disassembly:

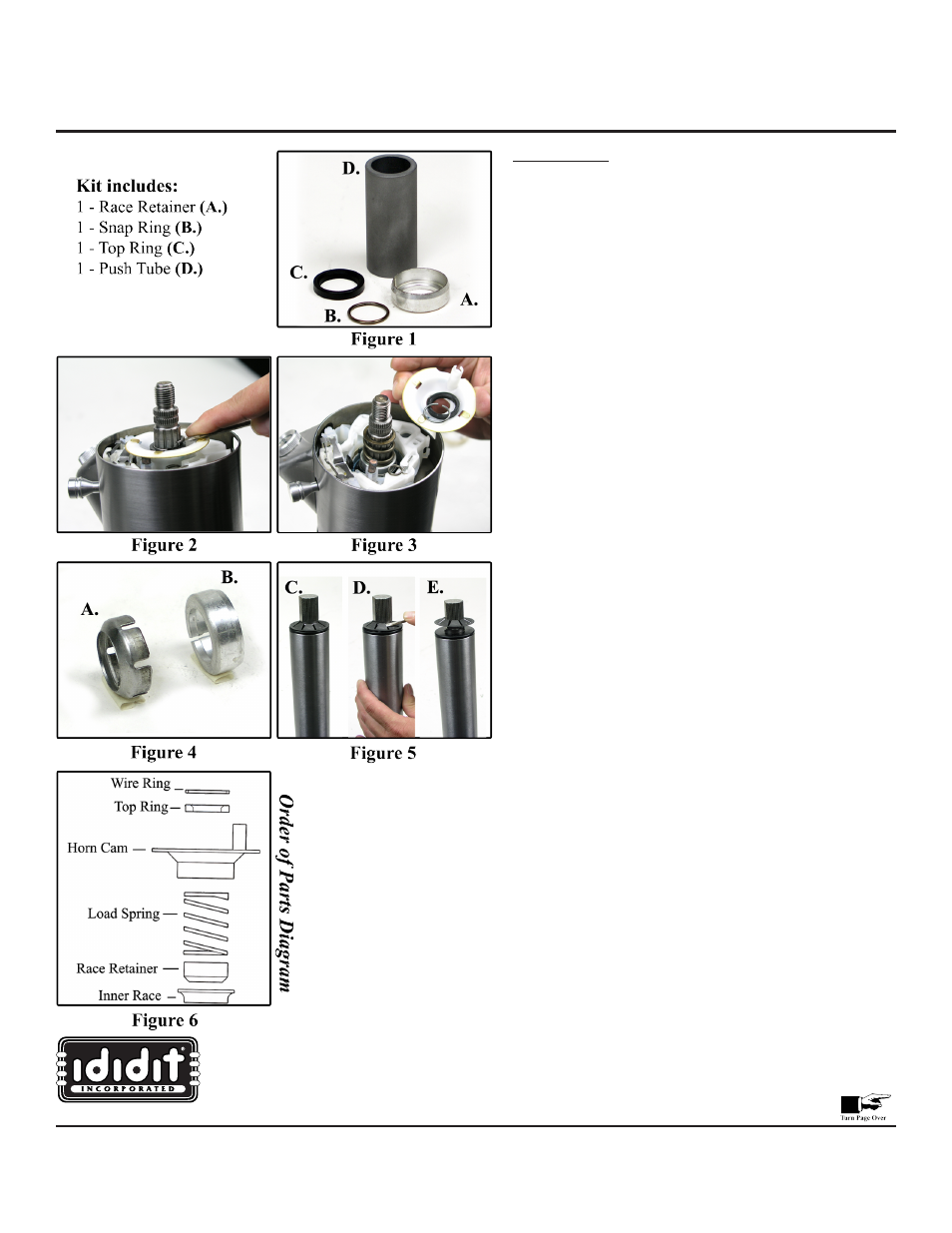

This kit is used to repair and re-assemble a tilt steering

column. The only tools necessary to do this job is a #1

regular screwdriver and a pair of needle nose pliers.

We will assume your column is fully assembled as we

will start these instructions at the beginning steps.

1. Remove steering wheel and adaptor (if equipped).

2. Before removing the snap ring, you should be aware

there is a strong spring that sets the preload on the

bearings. This spring has a stroke of ¼ inch. So be

prepared for the horn cam to jump at you!!

3. Use the #1 screwdriver to pry the snap ring out of its

groove. If necessary you can destroy the ring, as a

new one is included with the kit.

(Figure 2)

4. Now with the tension released, you can pull the horn

cam up and off the column, then you will see (and can

remove) the spring.

(Figure 3)

5. Under the spring is the race retainer. Use the

screwdriver to remove this. It may be easier to use

two screwdrivers like chop sticks to pull this item

out.

(Figure 3)

6. There are two types of race retainers: Version one was

tin and loosely looks like a bottle cap. The second

version is a billet aluminum item. We will be using

the billet aluminum one.

(Figure 4 A. & B.)

We are constantly looking for improvements to our

products and there is one more that you should know

about. Please look at the bottom of your column. There

may be a push nut on the bottom of your column. If your

column is equipped with this item it must be moved

down the shaft away from the bushing at the bottom of

the column. This push nut will prevent the shaft of the

column from rising into contact with the bearings at the

top of the column. The easiest way to do this is to spin the

nut down. You could also work each of the fingers with

the screwdriver or a strong knife blade. Normally, if you

walk the nut down until it is sitting against the u-joint

or rag joint, this will be enough. It is not necessary to

remove the joint. When finished with this repair you can

push this nut back up till it loosely touches the bushing.

(Figure 5 C., D. & E.)