ididit Steering Wheel Adaptor: Banjo Adaptor to Wheel Shoppe Banjo Wheel User Manual

ididit For the car

PROPERTY OF

ididi

T, inc

PROPERTY OF

ididi

T, inc

PROPERTY OF

ididi

T, inc

PROPERTY OF

ididi

T, inc

PROPERTY OF

ididi

T, inc

PROPERTY OF

ididi

T, inc

ididit inc. 610 S. Maumee St. 49286 Tecumseh, MI PH: 517-424-0577 FAX: 517-424-7293

www.ididitinc.com

ididit Banjo Adaptor to a Wheel Shoppe Banjo Wheel

For Part Number’s 2208310020, 2208310030, 2208310040, 2208310051

Instruction #: 8000010010

REV 12/12

How to install...

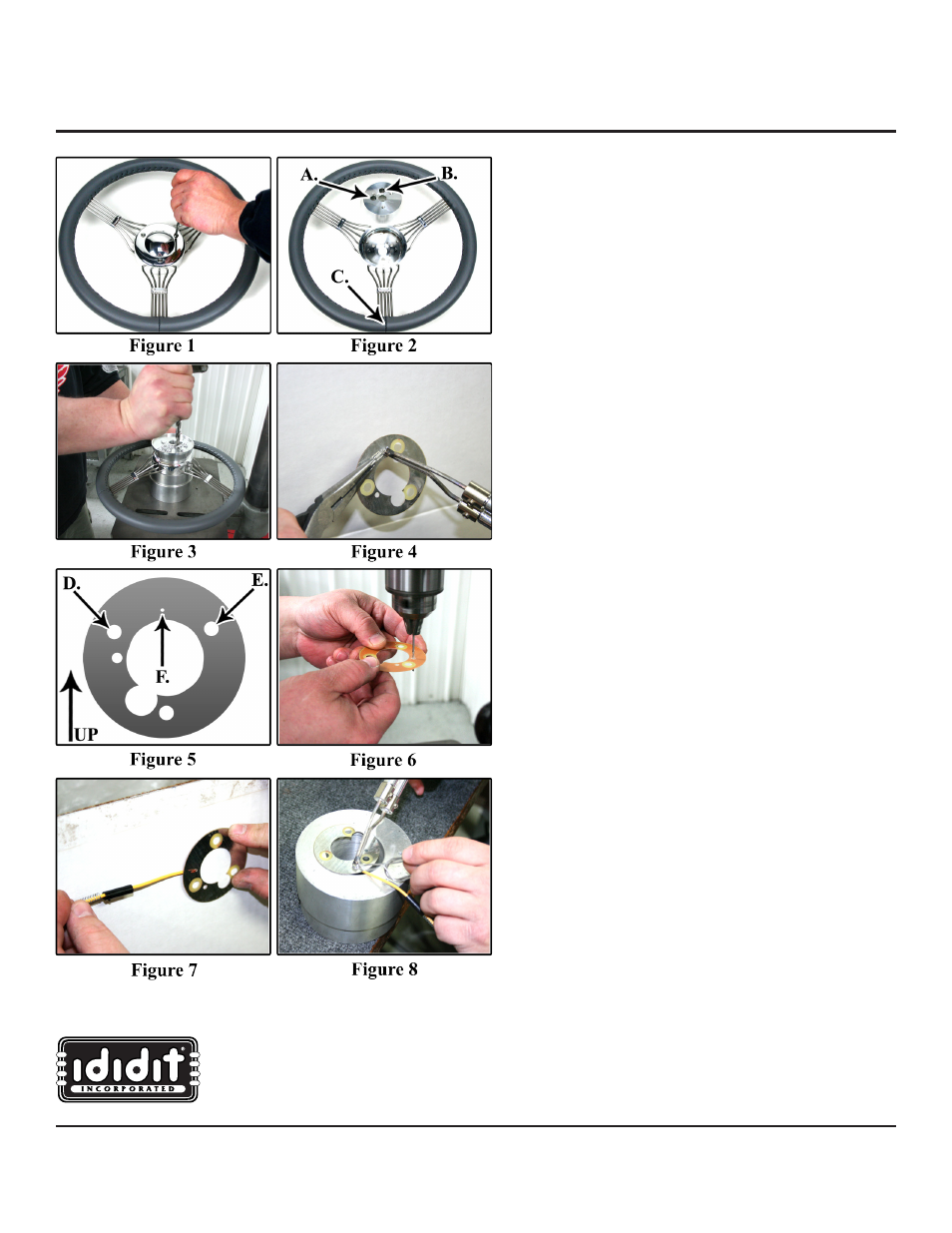

1. This hand wrapped Banjo Wheel is designed with

a seam in the leather, you will want the seam at

6:00 o’clock (straight down). This will give you a

clear view of the instruments. The manufacturer of

the wheel designed it to use a Grant 3 bolt pattern.

You will have to modify the wheel by drilling the

hole for the wire to pass through the wheel center

section and solder the wire onto the horn contact

plate. The operation goes like this….

2. Remove the 3 Allen screws from the front of the

wheel, along with the ring, horn assembly, and

contact plate.

(Figure 1)

3. Using the ¼”x28 thread button head screws, mount

the adaptor to the wheel so that hole B

(Figure 2

B.) is in the 10:30-12:00 O’clock position. The

seam in the leather must be in the 6:00 O’clock

position (straight down).

(Figure 2 C.)

4. Flip the wheel over. You will notice that the horn

wire hole needs to be drilled in the wheel.

5. Using a ½” drill and the adaptor as a guide, drill

through the wheel. You may want to put something

under the wheel to protect the leather. Once this is

done, you will need to debur both sides of the new

hole.

(Figure 3)

6. Unsolder the spade connector from the contact

plate.

(Figure 4)

7. Flip contact plate over and make a mark centered

between hole D and hole E 3/16”

(Figure 5 D. &

E.) from edge of the center I.D. Using a 5/64” drill

bit, pop a hole through the contact plate.

(Figure 5

F.)

8. Insert the stripped end of the wire through the

backside of contact plate using the new hole.

(Figure 7)

9. Bend bare wires over and resolder to the contact

plate.

(Figure 8)