Handle the su bstrate, 42 chapter 4 handle the substrate enww – HP Designjet L25500 Printer series User Manual

Page 46

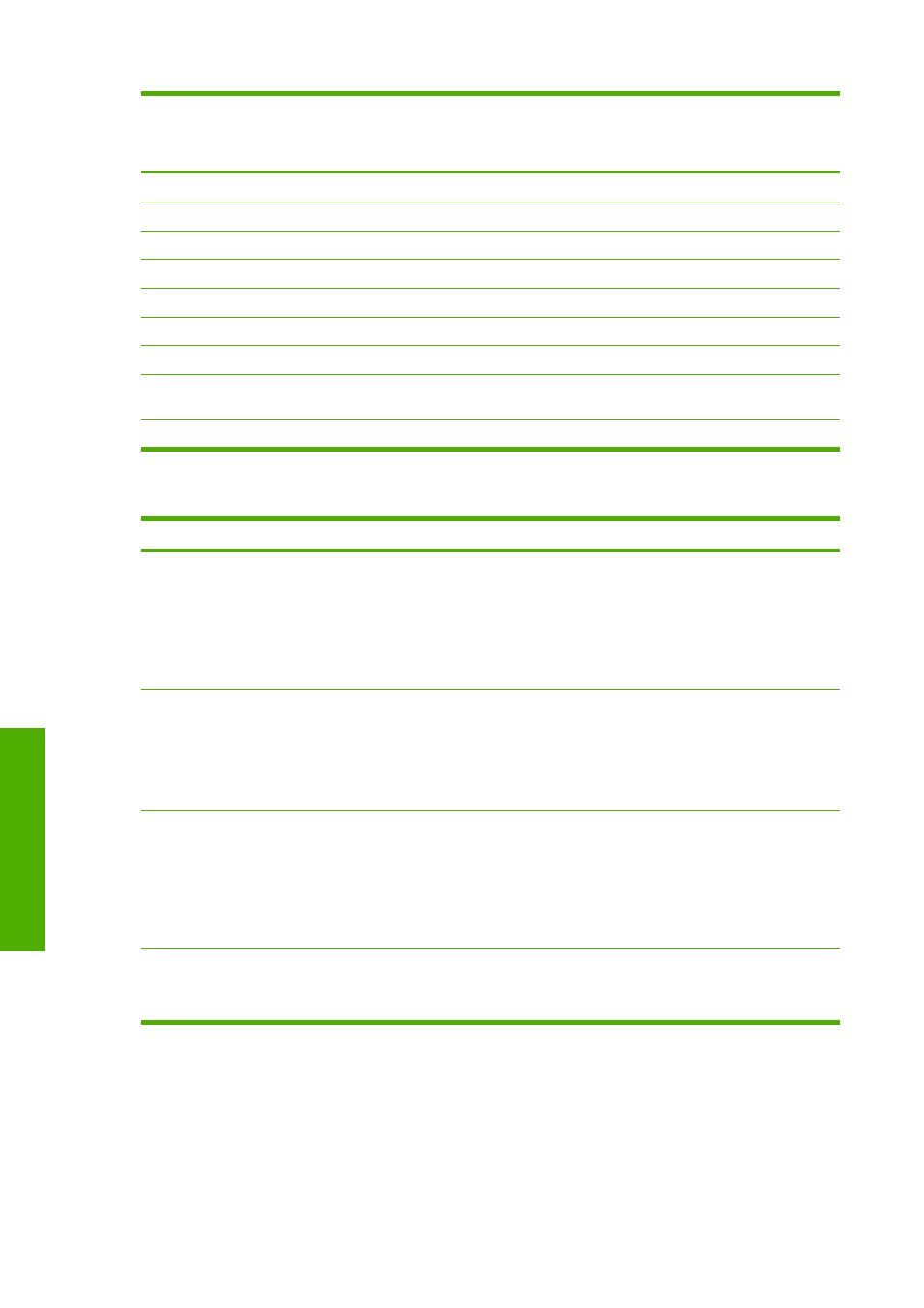

Substrate family

Drying

temp.

Curing

temp.

Heating

airflow

Auto-

tracking

(OMAS)

Cutter

Substrate

-advance

compens

ation

Input

tension

Vacuum

Self-adhesive vinyl

55

110

30

Yes

Yes

0

15

25

Banner

50

110

45

Yes

No

0

15

5

Film

55

95

30

Yes

Yes

0

15

25

Fabric

55

100

45

Yes

No

0

15

20

Mesh

50

95

30

Yes

Yes

0

15

30

Paper-Aqueous

45

70

30

Yes

Yes

0

15

20

Paper-Solvent

50

90

30

Yes

Yes

0

15

25

HP Photorealistic-Low

Temperature Substrate

50

80

30

Yes

Yes

0

15

40

Synthetic paper

50

80

30

Yes

Yes

0

15

40

The various settings mentioned above are described below.

Setting

Description

If too low

If too high

Passes

The number of passes specifies

how many times the printheads

will print over the same area of

the substrate.

The amount of ink fired per time

unit is larger and ink has less

time to dry on the substrate. This

may create coalescence and

banding. The boundaries

between passes may be more

visible. However, printing speed

is relatively high

Colors are vivid, print quality is

high. However, printing speed is

relatively low.

Drying temp.

The heat applied in the printing

zone removes water and fixes

the image to the substrate.

Print-quality defects such as

banding, bleeding and

coalescence may occur.

Thermal marks may be seen on

the substrate; they may appear

as vertical bands in some colors.

The substrate may wrinkle on the

platen, causing vertical banding,

ink smears or substrate jams.

Curing temp.

Curing is needed to coalesce the

latex, creating a polymeric film

which acts as a protective layer,

while at the same time removing

the remaining co-solvents from

the print. Curing is vital to ensure

the durability of the printed

images.

The print may emerge not fully

polymerized, so that the ink

smears when rubbed with a

finger. The print may appear wet,

after printing or later.

The substrate may wrinkle under

the curing module, causing

defects such as bubbles or liner

detachment. The substrate

wrinkles may also cause vertical

banding or ink smears at the

beginning of the following plot.

Heating Airflow

Airflow helps to remove the

evaporated water from the print

zone and thus allows more

efficient drying.

In general use the substrate family default value.

42

Chapter 4 Handle the substrate

ENWW

Handle the su

bstrate