Calibration – Setra System 264 User Manual

Page 2

2

4.0. CALIBRATION

The 264 transducer is factory calibrated and should require no field adjust-

ment. Generally, the mounting position will have a zero shift effect on ranges

below 1” WC. Whenever possible, any zero and/or span offsets should be

corrected by software adjustment in the user’s control system. However, both

zero and span adjustments are accessible either on the front of the unit or by

removing the optional conduit enclosure. The 264 transducer is calibrated in

the vertical position at the factory.

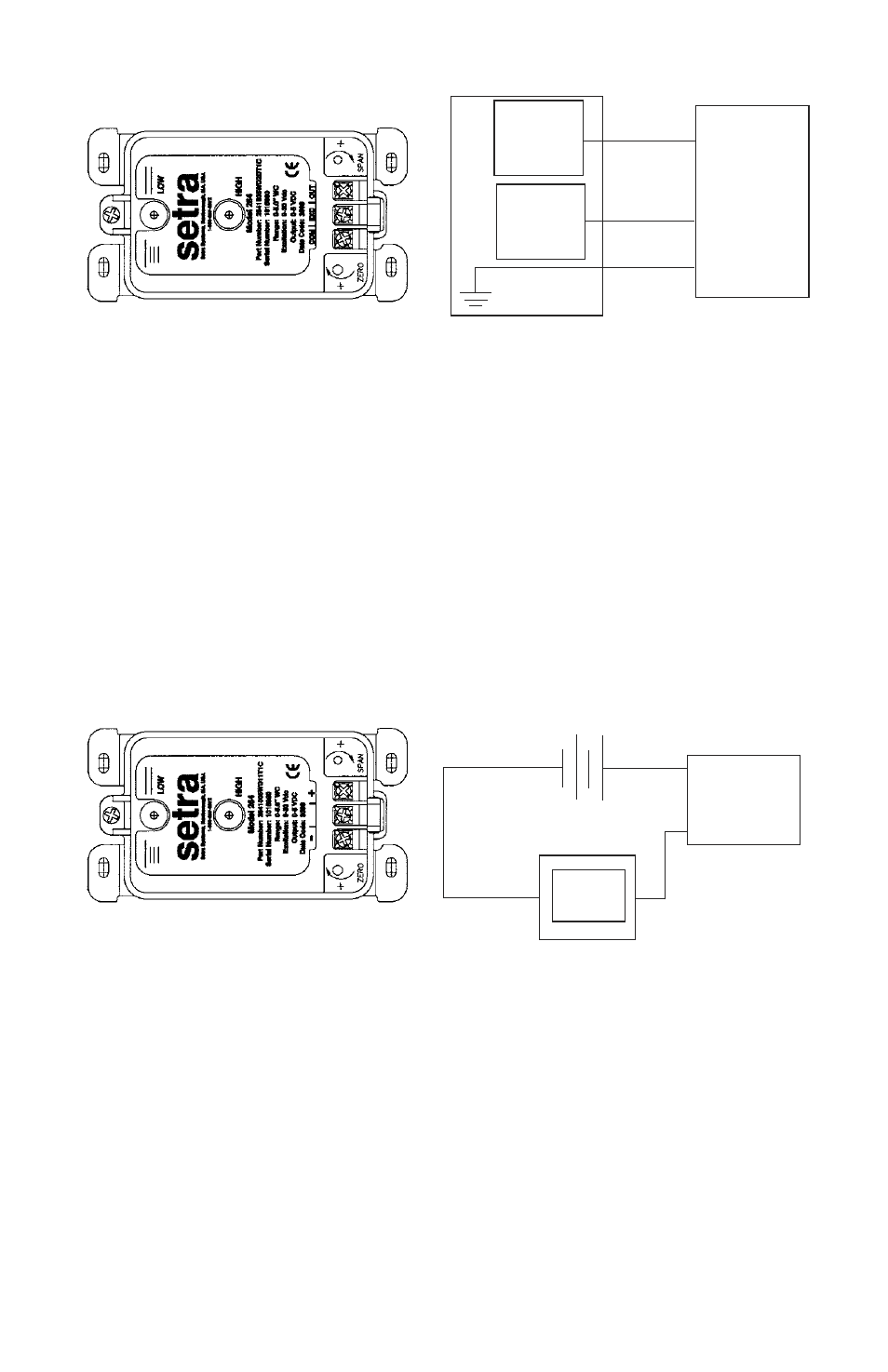

4.1 Voltage Output Zero Adjustment

While monitoring the voltage between the positive output (OUT) and

common (COM), and with both pressure ports open to atmosphere, the zero

may be adjusted by turning the zero adjustment screw. (See Diagram 1 for

Diagram 4

264

Current

Monitoring

Device

9 to 30 VDC

+

_

Diagram 2

Current Circuit Diagram

3.2 Current Output Units

The Model 264 is a two-wire loop-powered 4 to 20mA current output unit and

delivers rated current into any external load of 0 to 800 ohms. These terminals

have the designation of + and - (See Diagram 3). The current flows into the +

terminal and returns back to the power supply through the - terminal (See

Diagram 4). The power supply must be a DC voltage source with a voltage

range between 9 and 30 measured between the + and - terminals. The

unit is calibrated at the factory with a 24 VDC loop supply voltage and a 250

ohm load.

Diagram 1

Diagram 3

+ OUT

Connect to positive terminal

of control or pressure

monitor

+EXC

Connected to positive terminal of DC power supply

COM

Connect as the reference for power supply and

output signal

COM

OUT

Power

Supply

Readout

or

DAS

EXC

Model

264

Voltage Circuit Diagram