3 making a single-axis measurement, Making a single-axis measurement, Table 5-2: sam axis select bits – PNI RM3000-F Evaluation Board User Manual

Page 16

PNI Sensor Corporation

Doc #1016391 r04

RM3000-f Evaluation Board User Manual

Page 15

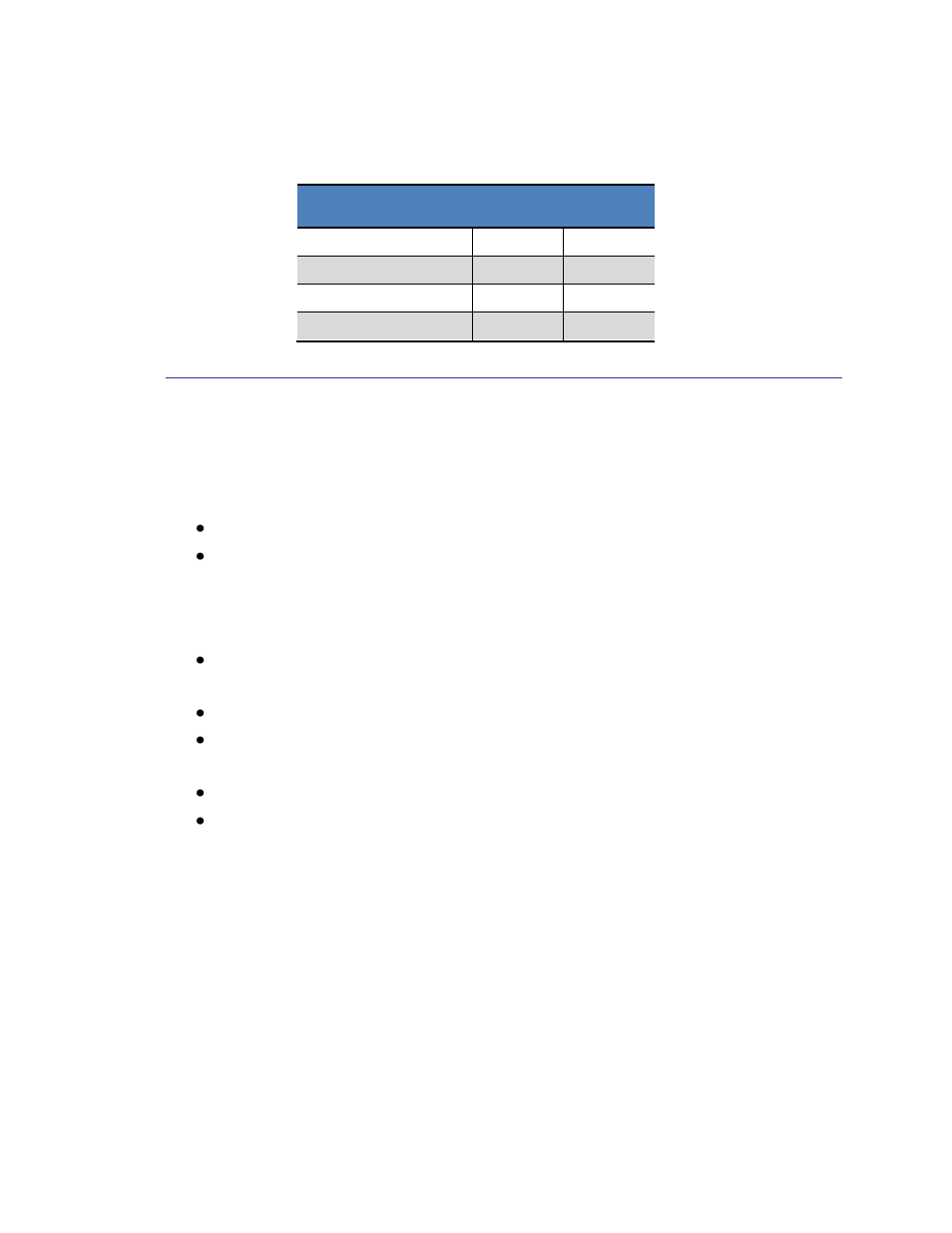

Table 5-2: SAM Axis Select Bits

Description

AS1

AS0

No axis measured

0

0

X axis (Channel 1)

0

1

Y axis (Channel 2)

1

0

Z axis (Channel 3)

1

1

5.2.3 Making a Single-Axis Measurement

The steps to make an interrupt-driven single-axis sensor measurement are given below.

The 3D MagIC will return the result of a complete forward-reverse measurement of the

sensor in a 24-bit 2’s complement format (range: -8388608 to 8388607).

SSN pin is set LOW. This enables communication with the master device.

The SAM Command Byte is clocked into the 3D MagIC on the MOSI pin.

Simultaneously, the 3D MagIC will present a fixed 0x9A on the MISO pin. Once

the 8 bits have clocked in, the 3D MagIC will execute the command (i.e. take a

measurement).

The SSN input may be returned HIGH at this point to free up host communication

with another device if desired. This will not affect the measurement process.

A measurement is taken.

At the end of the measurement, the DRDY pin is set HIGH, indicating data is

ready, and the 3D MagIC is placed in Idle Mode.

The SSN input should be set LOW, if it is not already, to read the data.

The data is clocked out on the MISO pin with the next 24 clock cycles.

If another measurement is immediately made, SSN can remain LOW and the process

repeated. Otherwise it is recommended that SSN is set HIGH to release the SPI bus.