3 connection of the rev-counter, Installation – NORD Drivesystems Berges-VG User Manual

Page 17

1

2

3

4

5

6

4.4.3

Connection of the rev-counter

The electrical rev-counter is an option and can be retrofitted at any time. The rev -

counter is supplied with a connection cable. This is connected user-specifically - if

using an indicator provided by the customer - or in accordance with the regulations

for the BERGES indicator.

Pulse encoder

The rotational speed is measured without physical contact using a rotating perforated

disc which simultaneously serves to secure the spring pulley and stationary pulse

encoder.

The pulse encoder generates a digital signal in conjunction with a NAMUR input.

Suitable BERGES indicators:

Technical Data pulse encoder:

Digital indicator unit DVM 120 D1

Housing

High-grade steel, stainless

- for supply voltage 24V-DC / 230V-AC

Connection -

2m PVC-cable 2x0.14

Digital indicator unit DA4 / EX- 40

cable *

2x 0,34mm

2

- for supply voltage 24V-DC / 230V-AC

Contr. circuits

DIN 19234 resp. Namur

in connection with a isolating transformer and

Rated voltage

10V

a frequency current transformer.

Sensing dist.

0......1,62 mm

Analogue indicator FFA 96

EMV to

EN 60947 - 5 - 2

- for supply voltage 24V-DC / 230V-AC

* with angle connector

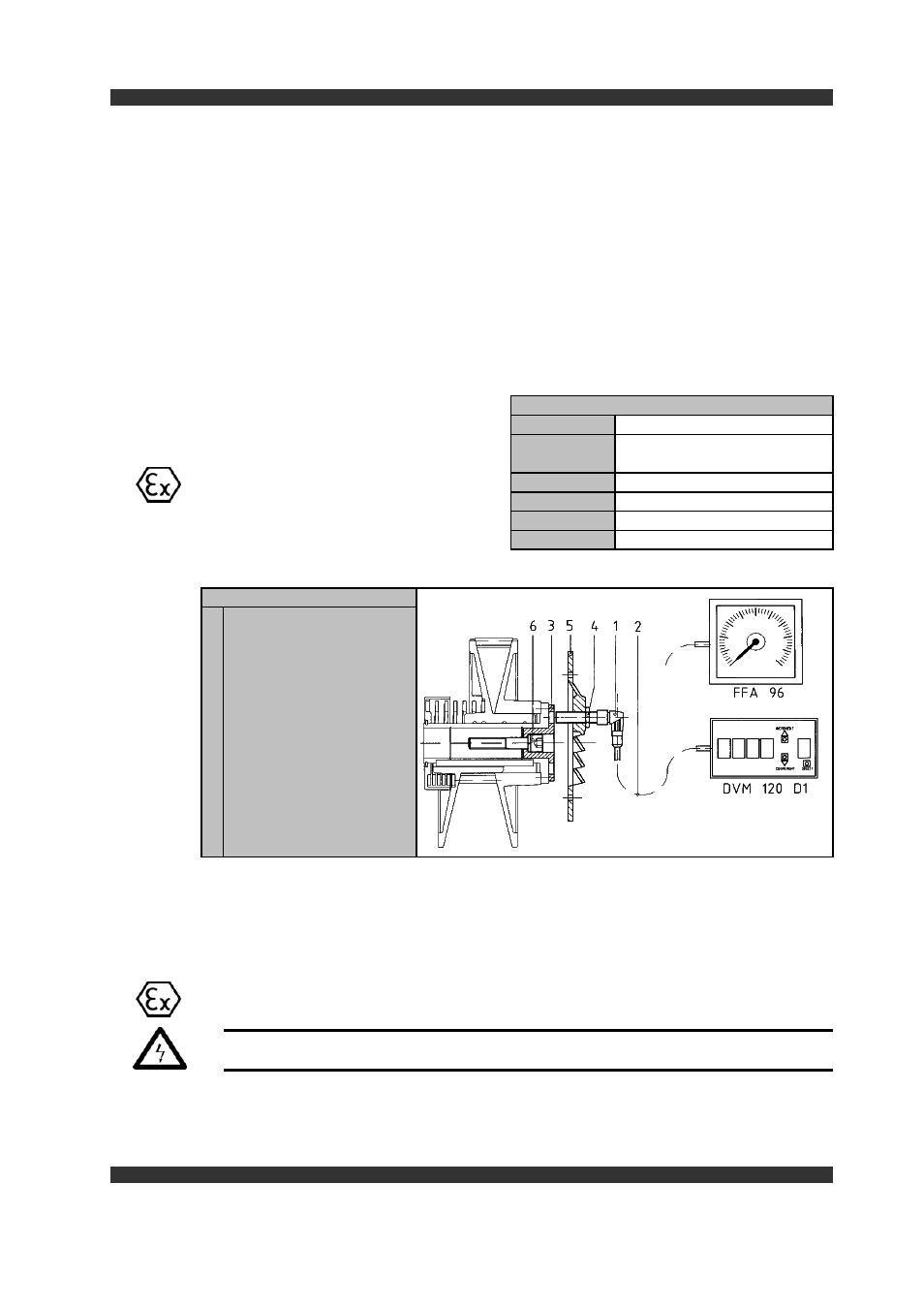

Figure 8 Pulse encoder

Pulse encoder

Connection cable 2m

( optionally 5m )

Perforated disc

Securing nut

( incremental encoder )

Fan cover

Securing screw

(perforated disc a.Fpulley )

1. Insert the collar of the perforated disc

( Item 3 )

into the bore of the spring pulley

and secure it with the securing screw ( Item 6 ) in the output shaft.

2. Screw the pulse encoder

( Item 1 )

into the ventilation cover

( Item 5 ).

3. Set the measuring gap: Screw the pulse encoder

( Item 1 )

fully against the per-

forated disc

( Item 3 ) ,

turn it back one turn ( sensing distance approx. 1 mm )

and lock with the nut ( Item 4 ) with respect to the ventilation cover ( Item 5 ).

4. Pulse meter to be turned back 2 revolutions (clearance distance about 2 mm)

Caution !

Ensure that the pulse encoder ( Item 1 ) is not screwed into a bore in the

perforated disc.

4. Install the indicator and connect it as shown in the connection diagram.

5. Adjust the reading: ( see separate Operating Instructions supplied with the

indictor ).

17

Installation