Nordisc, Adjustable speed drives, Warning – NORD Drivesystems U21010 User Manual

Page 2: Nord gear corporation, Nord gear limited

5. Friction disc replacement

A. Separate the driven disc assembly from the driving disc

assembly (See Separate Instructions).

B. Once the friction disc (Item 409), is exposed remove the

socket head cap screws (Item 410) that hold the friction

disc or friction ring (Item 409) to the friction disc carrier

(Item

407).

C. Clean the contact surface between the friction disc and

friction disc carrier.

D. Vacuum or brush out the NORDISC™ drive housing to

remove accumulated friction material dust. Be careful

not to ingest dust while cleaning.

E. Inspect main housing for damaged parts while

disassembled.

F. Attach the new friction disc to the carrier using the

socket head cap screws. Permissible tightening torques

are per the table below:

Type

Screw

Size

Material

Grade

Tightening

Torque

RV10

M5 X 12

8.8

6 N-m / 53 lb-in

RV20

M5 X 16

8.8

6 N-m / 53 lb-in

RV30

M6 x 16

8.8

10 N-m / 88 lb-in

RV40

M6 x 20

8.8

10 N-m / 88 lb-in

G. Re-assemble intermediate housing or “RV” housing

(Item 447) to output bearing housing (Item 402). To

re-assemble, apply Steps 1-4 in reverse order. Use a

thread-locking compound to secure the hex head

screws.

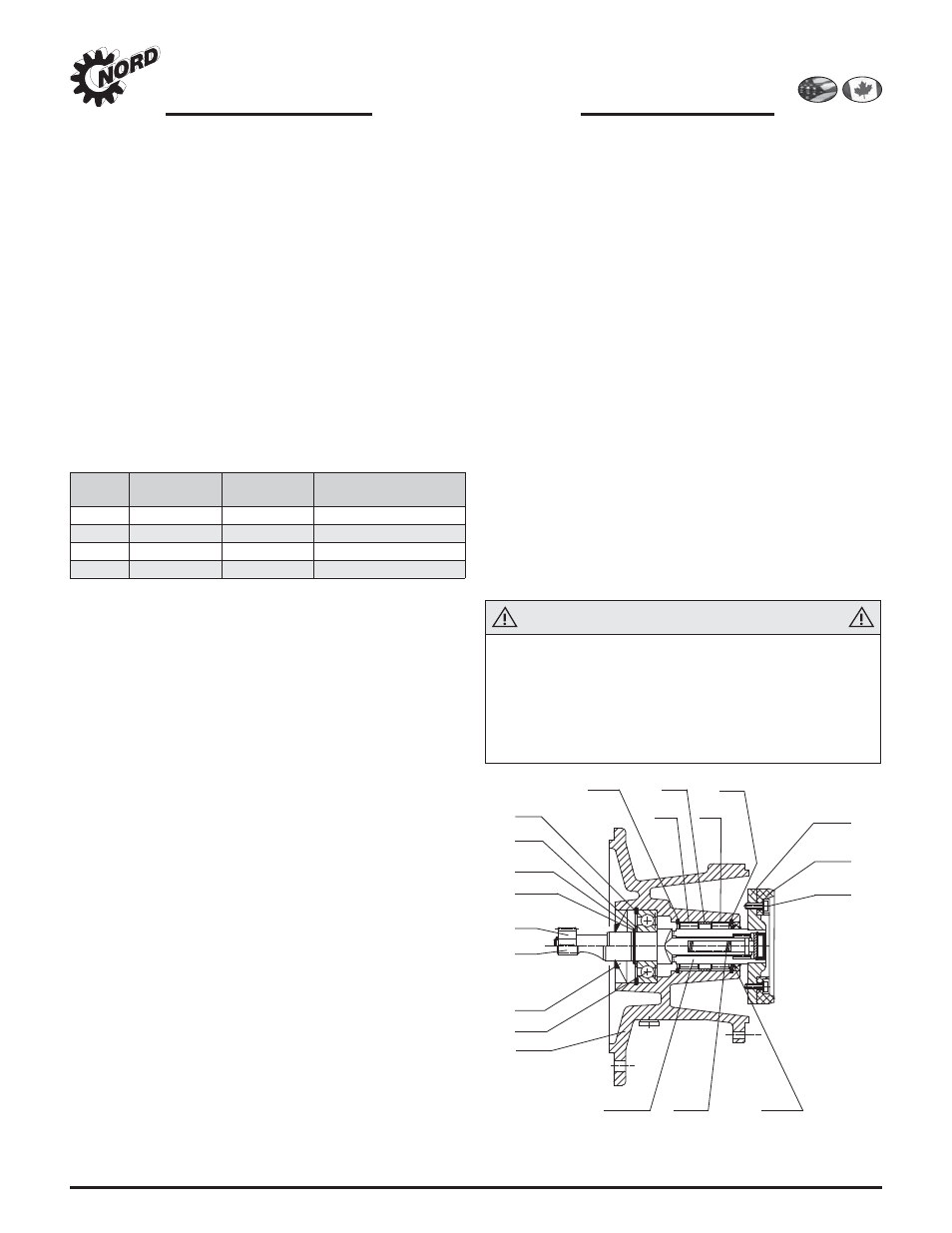

6. Bearing and seal replacement - NORDISC™ output

A. Separate the driven disc assembly from the driving disc

assembly (See Separate Instructions).

B. Slide the intermediate housing (Item 447) away from

the output housing (Item 402) and remove the shaft oil

seal (Item 439).

C. Remove circlips/snap-rings (Item 437 and 438).

D. Remove shims and supporting disc (Items 434 & 436).

E. Slide the hollow shaft/friction disc carrier assembly

(Item 404) away from output housing (Item 402).

F. Press output gear-shaft (Item 424 or 425) and bearing

(Item 435) out of output housing. Shaft and bearing

come out on the output or gear-shaft side.

G. Remove oil seal (Item 421) from output housing.

H. Remove two circlips/snap-rings (Items 418) from output

housing and remove needle bearings and spacer (Items

419 and 420).

I. Re-assemble in the reverse order, replacing ball bearing,

needle bearings, and oil seals (Items 435, 419, 421 and

439). If required, also replace any shims, spacers, or

circlips (Items 434, 436, 420, 437, 438, and 418).

During assembly, repack bearings with a lithium-based

NLGI #2 grease. Needle bearing cavity should be

approximately 1/3 full after re-greasing.

WARNING

• The output shaft compression spring (Item 430) does

not require maintenance. If the spring fractures the

complete shaft should be replaced as a complete

assembly or returned to NORD Gear for repair.

• Special fi xtures are required to remove and install the

spring. Personal injury can result if this repair is

attempted in the fi eld.

424

425

437

434

436

438

439

435

402

404

430

421

410

409

407

418

418

419

420

419

DRIVESYSTEMS

NORDISC

™

ADJUSTABLE SPEED DRIVES

RETAIN FOR FUTURE USE

U21010 - 2 of 6

www.nord.com/docs

06.09.09

NORD Gear Corporation

Toll Free in the United States: 888.314.6673

NORD Gear Limited

Toll Free in Canada: 800.668.4378