NORD Drivesystems U21010 User Manual

Nordisc, Adjustable speed drives, Harmful situation

DRIVESYSTEMS

NORDISC

™

ADJUSTABLE SPEED DRIVES

RETAIN FOR FUTURE USE

1. Basic operation and speed adjustment

The NORDISC™ Friction Drive will supply infi nite variable

speed adjustments over a fi xed speed range. The NORDISC™

Drive consists of a motor, dry traction drive, and main gear

drive. The motor is typically furnished as an integral mount

to the traction drive, however a NEMA C-face Input Adapter

(Flex-C-Input Adapter) is also available.

Attached to the output shaft of a constant speed motor, is

the driving disc portion of the traction drive. The driven disc

is angled approximately 2º, localizing the friction contact on

the disc pair. As the adjustment spindle is rotated, the input

side of the housing moves either up or down, changing the

effective pitch diameter of the driving disc. Speed is typically

adjusted by the handwheel.

STOP

HARMFUL SITUATION

STOP

Speed adjustments must be performed when the motor is

running to prevent possible damage to the traction drive

parts.

STOP

HARMFUL SITUATION

STOP

Initial adjustments of the speed stops located internal to

the traction drive are completed at the factory. Further

adjustments of the speed stops can cause damage to the

traction drive and/or main drive.

2. NORDISC™ Friction Drive

The variable speed drive requires only minimal maintenance.

However, the friction ring is a wear item.

STOP

HARMFUL SITUATION

STOP

The traction drive should be periodically operated through

its entire speed range, in order to prevent localized wear

patterns on the driving disc and/or possible damage to the

driving disc.

The friction drive does not require lubrication unless it is

disassembled for an overhaul. Units should be checked pe-

riodically for:

• Increased noise level.

• Increased operating temperatures.

• Increased

vibration.

• Increased motor amperage draw.

• Increased or excessive shaft movement.

Every 10,000 hours of operation, it is suggested that the

bearings be cleaned and re-greased with a lithium-based

NLGI #2 Grease.

The adjustment wheel and speed adjustment shaft should

also be cleaned periodically and coated with molybdenum-

based anti-seize compound.

3. Motor

WARNING

To prevent possible injury and/or damage to the electric

motor, the variable speed drive, or the driven equipment,

it is important to follow the motor manufacturer’s instruc-

tions pertaining to safe handling, installation, and mainte-

nance of the electric motor.

Connect the motor in accordance with the wiring informa-

tion supplied by the motor manufacturer and make sure the

motor nameplage voltage and frequency agree with the

available power supply. Use the proper protective motor

switches to help protect the motor windings from overload

and/or phase failure.

WARNING

Explosion proof motors should not be used on the friction

drive. The friction drive is not recommended for use in

explosion proof atmospheres.

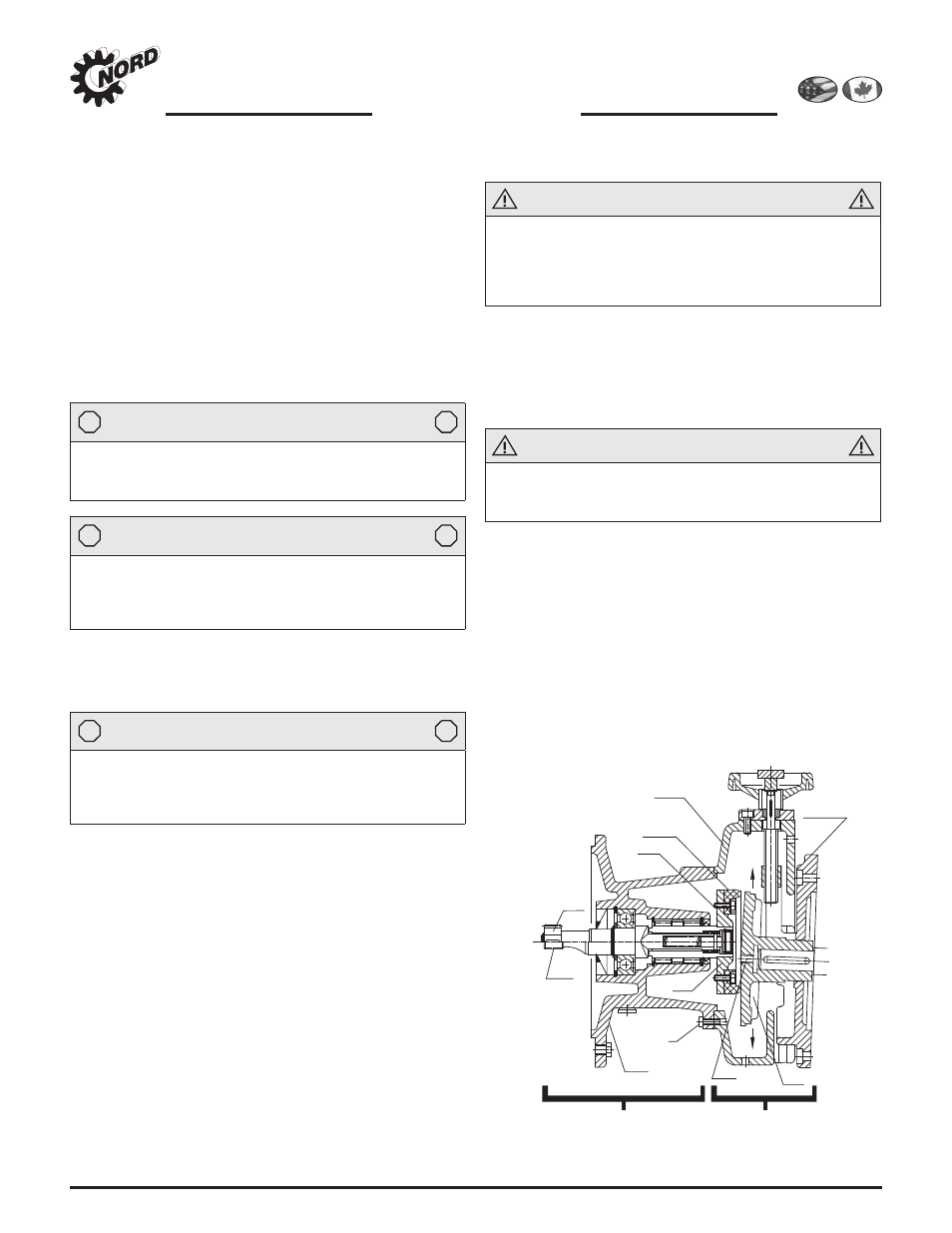

4. Seperating the driven disc assembly from the

driving disc assembly

A. Lockout the electric power to the motor and make sure

the wires are disconnected.

B. Support the intermediate housing (Item 447) and the

attached motor assembly.

C. Remove the four hex head screws that connect the

driving disc assembly (intermediate housing / Item 447)

to the driven disc assembly (output housing / Item 402).

D. Slide the intermediate housing (Item 447) away from the

output housing (Item 402).

489

409

447

Hex Head

Screws (4X)

410

493

407

472 (474)

402

424

425

DRIVE DISK ASSEMBLY

DRIVEN DISK ASSEMBLY

U21010 - 1 of 6

www.nord.com/docs

06.09.09

NORD Gear Corporation

Toll Free in the United States: 888.314.6673

NORD Gear Limited

Toll Free in Canada: 800.668.4378