NORD Drivesystems B1091 User Manual

Page 8

-8-

B1091-GB-4613

www.nord.com

5. Motors with ignition protection

class "increased safety Exe"

The following supplementary or the following specific information applies for these motors.

The motors are suitable for use in Zone 1 and conform to equipment group II, category 2G, and may be used

at an ambient temperature between -20°C and +40°C.

Type supplement: 2G e.g.: 80 L/4 2G TF

The marking is

0102 II 2G Ex e IIC T3 Gb with details of the temperature class.

If the motor is attached to a gear unit, the EX labelling of the gear unit must also be observed!

Explosive gas mixtures or concentrations of dust in conjunction with hot, live and moving parts on electrical

machinery can cause severe or fatal injuries.

The increased hazard in explosive areas calls for particularly careful compliance with the general safety and

commissioning instructions. The staff responsible must be trained regarding correct use of motors in

explosive areas.

Explosion-protected electrical machines comply with the standards in series EN 60034 (VDE 0530) as well

as EN 60079-0:2009 and EN 60079-7:2007. The degree of explosion risk determines the zone classification.

DIN EN 60079, Part 10, provides information on this. The user is responsible for the zone classification. It is

prohibited to use motors which are not certified for explosive areas in explosive areas.

Cable glands must be approved for explosive atmospheres. Openings which are not used must be closed off

with approved blind plugs. When connecting installation lines, the connections to the motor terminals and the

earth lead must be bent into a U-shape under the respective terminals so that the terminal clamps and studs

are subjected to uniform loading and are not deformed under any circumstances. Alternatively, the

connections can be made with a cable lug.

The use of aluminium connecting cables is not permissible.

All motors with the protection class Ex e are supplied with certified cable glands.

Cables with a circular cross-section must be used with the cable glands which are supplied. The clamping

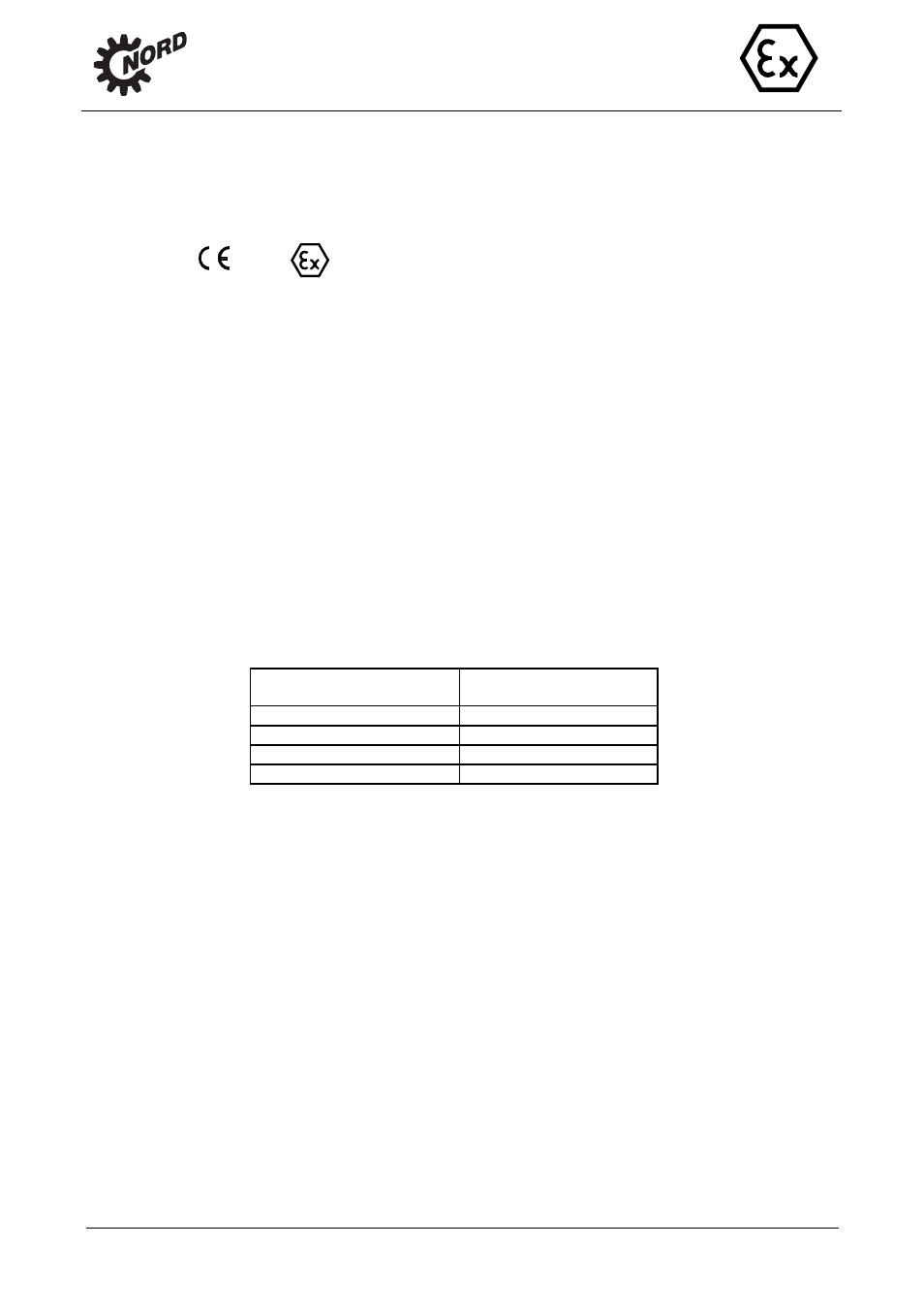

nuts of the cable gland must be tightened to the torque specified in the following table.

Cable gland

Clamping nut

tightening torque [Nm]

M20x1.5 6

M25x1.5 8

M32x1.5 12

M40x1.5 16

When connecting, always ensure that the permissible clearance distances of 10 mm and the permissible

creepage distances of 12 mm between live components and components with the housing potential or

between individual live components are observed.

Before the terminal box is closed, ensure that all the nuts on the terminals and the screw on the protective

earth terminal are tight. The terminal box seals and the seals on the cable gland must be fitted properly and

must not be damaged in any way.

If the shaft end is at the top, e.g. versions IMV3 or IMV6, and the motor has Exe protection, the user/installer

must fit a cover which prevents foreign bodies from falling into the motor fan cover (see DIN EN 60079-0).

This must not obstruct the fan from cooling the motor. If the shaft end is at the bottom, e.g. versions IMV1 or

IMV5, the motors are generally provided with a protective shield on the fan cover. A handwheel at the

second shaft end is not permitted.

The motors are designed for continuous operation and normal, non-recurring start-ups in which no

substantial start-up heat develops.

Section A in EN 60034-1 (VDE 0530 Part 1) - voltage ± 5%, frequency ± 2%, characteristic, mains

symmetry - must be complied with, so that the development of heat remains within the limits permitted.

Any major deviations from the rated values can cause an impermissible increase in the development of

heat in the motor.

The motor temperature class stated on the type plate must at least conform to the temperature class of any

combustible gas that may occur.