NORD Drivesystems B1091 User Manual

Page 18

-18-

B1091-GB-4613

www.nord.com

7. Motors for use in Zone 21 and Zone 22

according to EN 60079-0 and IEC 60079

If the end of the shaft faces upwards, e.g. version IMV3, IMV6, a cover must be provided by the operator /

installer, which prevents foreign bodies from falling into the fan cover of the motor (see DIN EN 60079-0,

Item 17, or IEC 60079). This must not obstruct the fan from cooling the motor. If the end of the shaft faces

downwards, e.g. versions IMV1, IMV5, motors for Zone 21 and Zone 22 are provided with a protective cover

on the fan cover. A handwheel on the second end of the shaft is not permitted for versions with the "shaft

end downwards".

Unless otherwise specified for operating modes and tolerances in the test certificate, the power rating plate

or in IECEx CoC, electrical machinery is designed for continuous operation and normal infrequent start-ups

where insignificant start-up heating occurs. The motors may only be used for the operating mode specified

on the type plate.

The installation instructions must be strictly observed.

7.4 Structure and method of use

The motors are self-cooling. Rotary shaft seals are fitted both on the drive side (DS) and on the ventilation

side (VS). Motors for Zone 21 and Zone 22 have metal fans. Motors with brakes for Zone 22 (Category 3D,

non-conducting dust) have a special plastic fan. The motors are produced with protection class IP55,

optionally protection class IP 66, (Zone 22 - non-conductive dust, EPL Dc) or IP66 (Zone 21, EPL Db). Under

normal operating conditions, the surface temperature does not exceed the surface temperature stated on the

type plate.

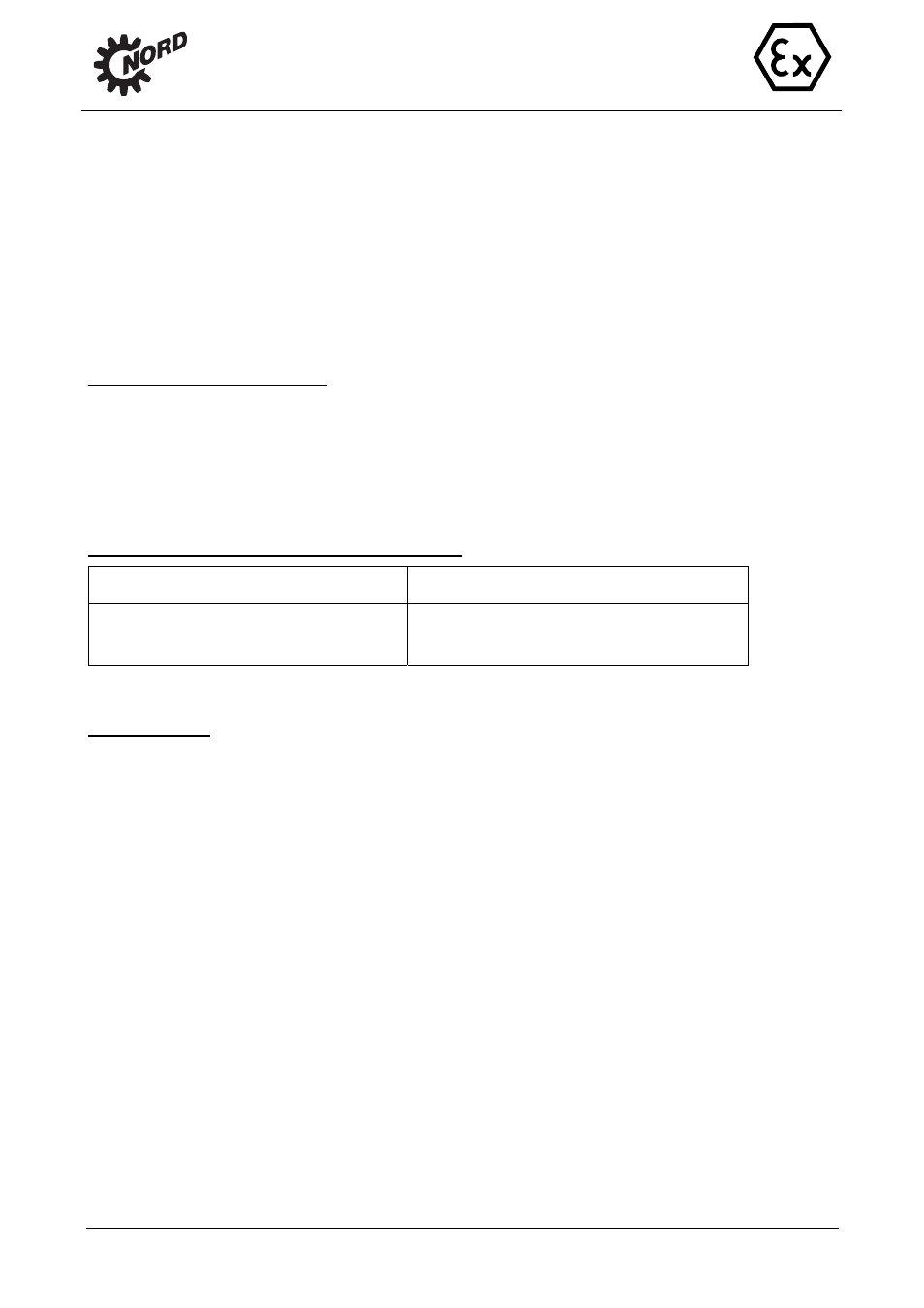

7.5 Minimum cross section of bonding conductors

Cross-section of phase conductor

of the installation S in mm

2

Minimum cross-section of the associated

earth lead S

P

in mm

2

S

≤ 16

16 < S

≤ 35

S > 35

S

16

0.5 S

When connecting a lead to the external earth, the minimum cross-section must be 4 mm

2

.

7.6 Maintenance

The voltage must always be switched off and secured against being switched on again before

opening the motor!

Notice ! Higher temperatures than the maximum permitted surface temperature of the housing may

be present inside the motor. The motor must therefore never be opened in hazardous dust

atmospheres! The motors must be checked and tested regularly for functional safety! The applicable

national standards and regulations must be complied with!

Impermissibly thick dust deposits > 5 mm must not be allowed to accumulate! If functional safety cannot be

ensured, the motor may not be operated! When the ball bearings are replaced, the rotary shaft seals must

also be replaced. FKM rotary shaft seals as specified by Getriebebau NORD must be used. Ensure that they

are fitted correctly! The rotary shaft seals must be lubricated on the external rings and on the seal lips. If an

explosion protected gear unit is flanged dust-tight to the motor, an NBR rotary shaft seal can be used on the

drive side of the motor if the gear oil temperature does not exceed 85°C. Only original parts may be used as

spare parts with the exception of standardised, commercially available and equivalent parts. This also

applies in particular to seals and connection components. Parts for terminal boxes or spare parts for external

earthing must be ordered according to the spare parts list in the operating instructions.

The functionality of seals, rotary shaft seals and cable glands must be regularly checked!

Maintenance of the dust protection is of paramount importance for explosion protection. Maintenance

must only be performed in a specialist workshop by qualified personnel. We urgently recommend that the

general overhaul is carried out by NORD Service.