NORD Drivesystems B1091 User Manual

Page 17

www.nord.com

B1091-GB-4613

-17-

7. Motors for use in Zone 21 and Zone 22

according to EN 60079-0 and IEC 60079

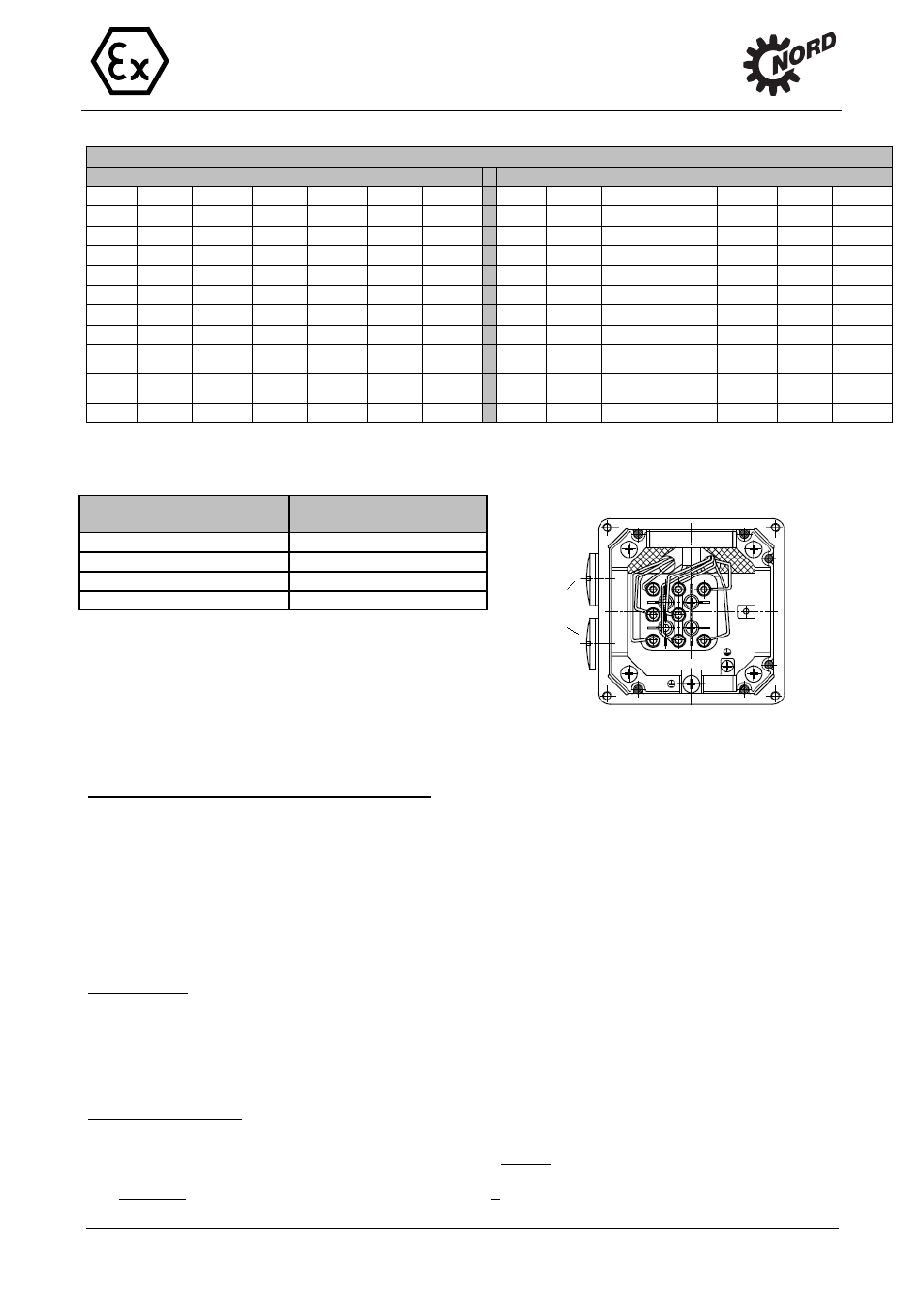

Assignment of Cable Glands to Motor Size

Cable glands for standard motors

Cable glands for brake motors

Type

Number Thread

Number Thread

Number Thread

Type

Number Thread

Number Thread

Number Thread

63

2

M20x1.5

63

4

M20x1.5

2

M12x1.5

71

2

M20x1.5

71

4

M20x1.5

2

M12x1.5

80

2

M25x1.5

80

4

M25x1.5

2

M12x1.5

90

2

M25x1.5

90

4

M25x1.5

2

M12x1.5

100

2

M32x1.5

100

4

M32x1.5

2

M12x1.5

112

2

M32x1.5

112

4

M32x1.5

2

M12x1.5

132

2

M32x1.5

132

4

M32x1.5

2

M12x1.5

2

M16x1.5

160/

180/..X

2

M40x1.5

2

M12x1.5

2

M16x1.5

160/

180/..X

2

M40x1.5

2

M12x1.5

2

M16x1.5

180/

200/..X

2

M40x1.5

2

M12x1.5

2

M16x1.5

180/

200/..X

2

M40x1.5

2

M12x1.5

2

M16x1.5

200

2

M40x1.5

2

M12x1.5

2

M16x1.5

200

2

M40x1.5

2

M12x1.5

2

M16x1.5

If the motor is supplied with a certified cable gland, the clamping nuts of the cable gland must be tightened to

the torque specified in the following table.

Cable gland

Clamping nut

tightening torque [Nm]

Cabl

e gland

M20x1.5 6

M25x1.5 8

M32x1.5 12

M40x1.5 16

7.3.3 Permissible Ambient Temperature Range

The permissible ambient temperature range for all motors is -20°C...+40°C. A greater ambient temperature

range of -20°C...+60°C is permissible with motors for operation in Zones 21 and 22. However, this does not

apply for the option brake and external fan! The rated power must however be reduced to 72% of the

catalogue value.

If the maximum ambient temperature is between +40°C and +60°C, the power output should be inversely

linearly interpolated between 100% and 72%. In this case thermal protection of the motor by means of a

thermistor sensor is mandatory. The motor connection cables and the cable glands must be suitable for

temperatures of at least 80°C.

7.3.4 Painting

Motors for Zone 21 and Zone 22 are provided with suitable painting ex-works.

Subsequent painting may only be carried out after consultation with Getriebebau NORD or with a workshop

which is approved for the repair of explosion protected motors. Compliance with the valid standards and

regulations is mandatory.

7.3.5 IEC-B14 Motors

The B14 flanged bearing cover must be covered with a protective foil which must be removed before the

motor is fastened in place. Even if they are not required, All four fixing screws must be screwed into the

flanged bearing cover! The fixing screw threads must be inserted with a sealant, e.g. Loctite 242.

The maximum depth for screwing into the bearing cover is 2 x d.