Appendix – NORD Drivesystems B1050 User Manual

Page 25

6. Appendix

-26- B1050-GB-0213

www.nord.com

Check the oil level

Section 6.1 describes the versions and the corresponding oil level screws. With double gear

units, the oil level must be checked on both units. The pressure vent must be at the position

marked in Section 6.1.

Gear unit types that are not supplied full of oil must be filled before the oil level is checked. (See

“Changing the oil”)

Checking the oil level:

1. The oil level may only be checked when the gear unit is at a standstill and has cooled

down. The gear unit must be secured to prevent accidental switch-on.

2. Gear units with oil level screw: The oil level screw corresponding to the version must be

screwed out. (See Section 6.1) The oil level in the gear unit must be checked and corrected

with the correct type of oil if necessary. The correct oil level is the middle of the inspection

glass.

3. Gear units with oil inspection glass or oil level glass: The oil level in the gear unit can be

seen directly in the viewing window. Correct with the correct type of oil if necessary.

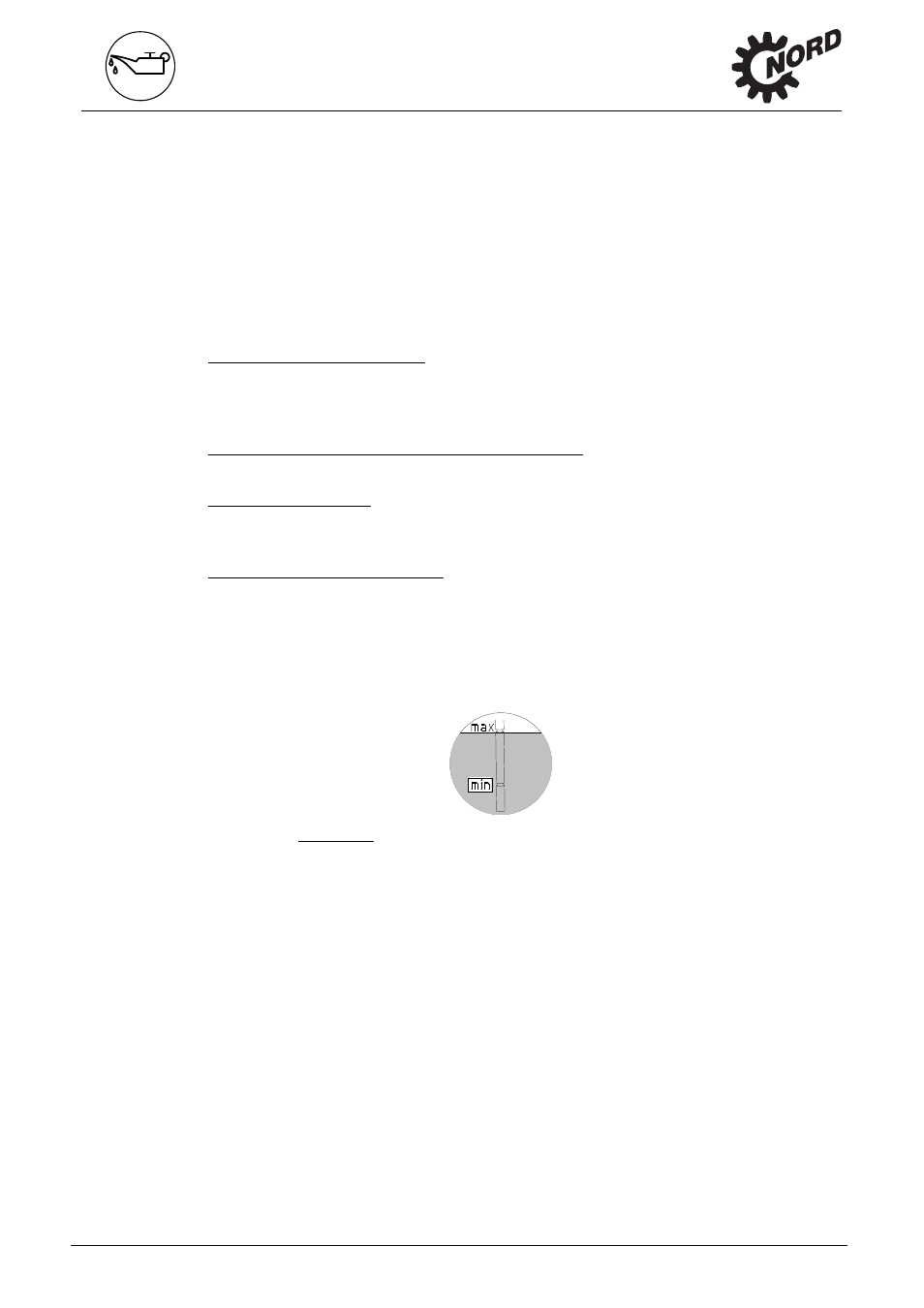

4. Gear units with dipstick: The oil level in the gear unit must be between the upper and lower

mark when the dipstick is completely screwed in (see Fig. 5-1). The oil level must be

corrected with the correct type of oil if necessary.

5. Gear units with an oil level vessel: The oil level must be checked in the oil level vessel with

the aid of the dipstick plug (thread G1 1/4). The oil level must be between the upper and

lower mark when the dipstick is completely screwed in (see Fig. 5-1). The oil level must be

corrected with the correct type of oil if necessary. These gearboxes may only be operated in

the configuration stated in Section 6.1.

6. The oil level screw or the cap screw with dipstick and all other loosened screws must be

correctly re-tightened.

Figure 5-1: Checking the oil level with a dipstick

Regreasing

Some gear unit designs (agitator designs VLII and VLIII) are equipped with a regreasing device.

Via the grease nipple, the external roller bearing is regreased with approx. 20-25g of grease.

Recommended grease: Petamo GHY 133N (see Section 6.2: Klüber Lubrication).

Checking the oil filter

The oil filters are quipped with a visual or electro-mechanical contamination indicator. If

contamination is indicated, the oil filter must be replaced according to the operating instructions

for the particular cooling system.