Storage, transport, preparation, installation – NORD Drivesystems B1050 User Manual

Page 15

3. Storage, Transport,

Preparation, Installation

-16- B1050-GB-0213

www.nord.com

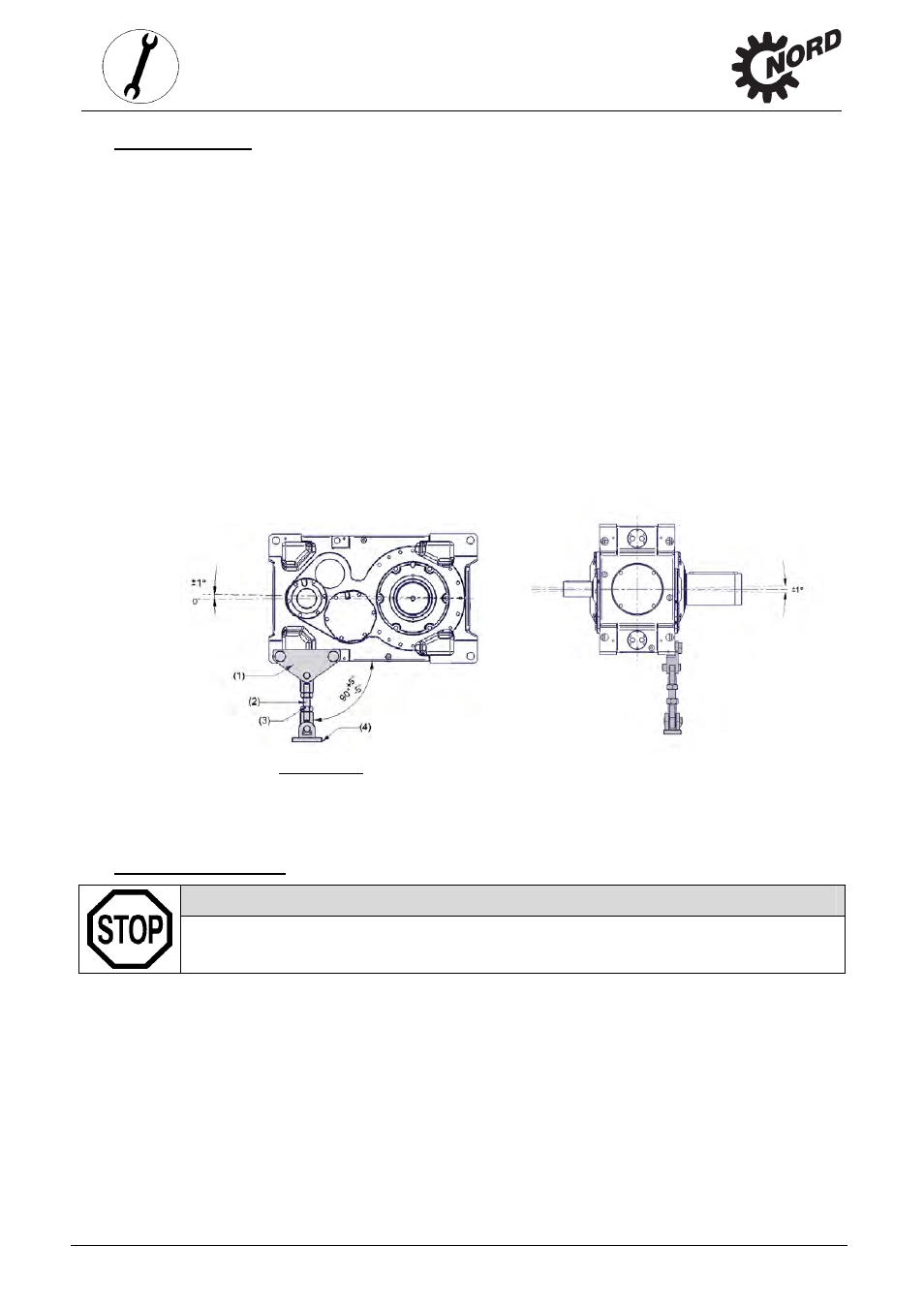

3.8 Torque support

The length of the torque support can be adjusted within a certain range. The torque support

consists of a fork head with a bolt (1), a threaded bolt (2), a maintenance-free joint head (3) and

a fork plate with a bolt (4).

Assembly should be carried out from the side of the machine, in order to reduce the bending

moment on the machine shaft. Tension and pressure and installation upwards or downwards are

not permissible.

Distortion of the torque support during assembly or operation must be avoided, as otherwise the

service life of the output shaft bearings may be reduced. Torque supports are not suitable for the

transfer of radial forces, therefore they may only be used in combination with motor mounts or

couplings which do not transfer radial forces.

For helical gear units with motor mounts, the torque support is located opposite to the motor

mount.

The gear unit is aligned horizontally with the threaded bolt and the nuts of the torque support

and must be secured with lock-nuts.

Figure 3-10: Permissible installation deviations of the torque support

3.9 Fitting shrink discs

Attention!

The operating instructions for the shrink disc must be observed.