Storage, transport, preparation, installation – NORD Drivesystems B1050 User Manual

Page 17

3. Storage, Transport,

Preparation, Installation

-18- B1050-GB-0213

www.nord.com

Assembly procedure to attach a standard motor to the IEC adapter (Option IEC)/NEMA adapter

1. Clean motor shaft and flange surfaces of motor and adapter and check for damage.

Mounting dimensions and tolerances of the motor must conform to DIN EN 50347/NEMA

MG1 Part 4.

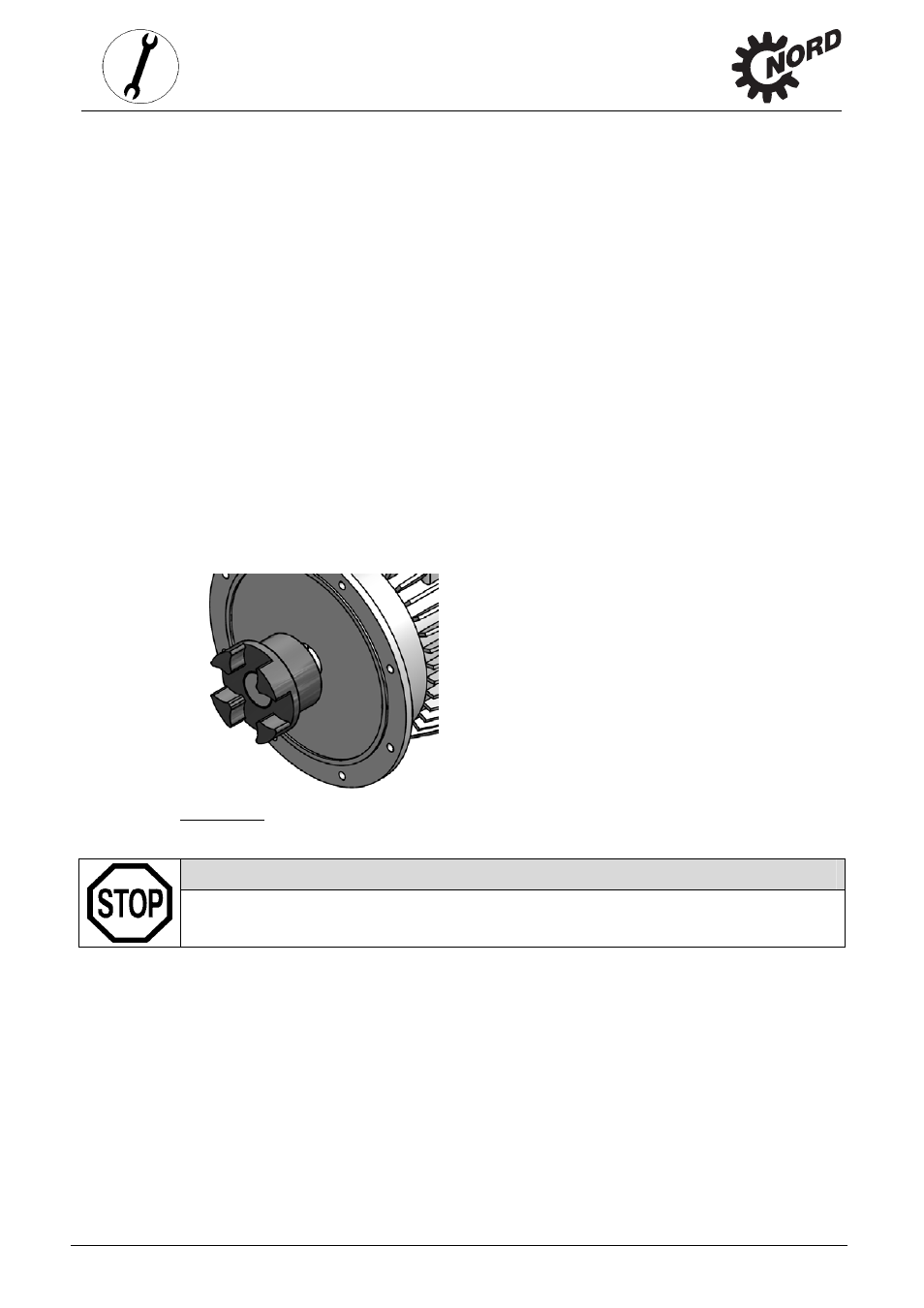

2. Push the coupling sleeve onto the motor shaft so that the motor parallel key engages into

the groove in the sleeve on tightening.

3. Pull the coupling sleeve onto the motor shaft according to the instructions of the motor

manufacturer. The shaft end of the motor must be adjusted so that it is parallel with the face

of the coupling. (See Figure 3-11)

4. Secure the coupling half with the threaded pin. The threaded pin must be coated prior to use

with a securing lubricant e.g. Loctite 242, Loxeal 54-03 and tightened to the correct torque.

(See Chapter 6.4 for torque values)

5. Sealing of the flange surfaces of the motor and the adapter is recommended if the motor is

installed outdoors or in a humid environment. The flange surfaces of motor and adapter

must be completely coated with surface sealant Loctite 574 or Loxeal 58-14 prior to

mounting so that the flange seals after mounting.

6. Mount the motor to the adapter; do not forget to fit the gear rim or the sleeve.

7. Tighten the adapter bolts to the correct torque. (See Chapter 6.4 for torque values)

Figure 3-11: Fitting the coupling to the motor shaft

Attention!

The operating instructions for the coupling must be observed.